HOME > Materials for small diameter tubes > NiTi Tubes (Nitinol, Nickel Titanium)

NiTi Tubes (Nitinol, Nickel Titanium)

NiTi Tubes (Nitinol, Nickel Titanium)

update :

Characteristics of NiTi Tubes

NiTi tube has the characteristics both of super-elastic alloy and of shape memory alloy. It has been employed especially in medical instruments for its excellent resiliency despite its difficulty in welding. (For welding parts, we recommend the use of β-titanium because it can complement NiTi tubes due to its excellent elasticity and weldability.)

Our super-elastic NiTi tubes feature excellent flexibility, kink-free, and shape memory property. They have been used for a variety of purposes such as cardiovascular translational operation and a catheter. About 40days will be necessary from receiving of a drawing to deliver of a product with your original specifications.

| type | Outer / Inner diameter (mm) |

|---|---|

| Superelastic Nitinol tube | 2.8 / 2.5 |

| Superelastic Nitinol tube | 2.5 / 2.2 |

| Superelastic Nitinol tube | 2.4 / 2.2 |

| Superelastic Nitinol tube | 3.0 / 2.0 |

| Spiral laser cut tube | 2.5 / 1.6 |

| Superelastic Nitinol tube | 1.8 / 1.6 |

| Superelastic Nitinol tube | 1.8 / 1.5 |

| Superelastic Nitinol tube | 1.2 / 1.1 |

| Superelastic Nitinol tube | 1.1 / 0.9 |

| Superelastic Nitinol tube | 1.0 / 0.8 |

| Superelastic Nitinol tube | 0.9 / 0.7 |

| Superelastic Nitinol tube | 0.9 / 0.6 |

| Superelastic Nitinol tube | 0.7 / 0.6 |

| Superelastic Nitinol tube | 0.5 / 0.4 |

| Superelastic Nitinol tube | 0.35 / 0.30 |

| Superelastic Nitinol tube | 0.4 / 0.2 |

| Superelastic Nitinol tube | 0.3 / 0.2 |

| Superelastic Nitinol tube | 0.20 / 0.14 |

| Superelastic Nitinol tube | 0.18 / 0.12 |

A series of options below can be included. Please feel free to contact us.

Optional Processes

Optional processes below are available. Please feel free to contact us.

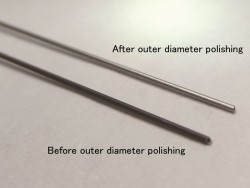

– Outer diameter polishing of tubes(Oxide film removal)

Centerless polishing and pickling can remove an oxide film on a tube surface with minimum intra-lot difference in the surface condition. You will recognize the beautiful surface even through a surgical camera.

Centerless polishing and pickling can remove an oxide film on a tube surface with minimum intra-lot difference in the surface condition. You will recognize the beautiful surface even through a surgical camera.

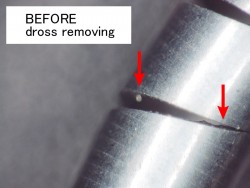

Laser processing

Generally, dross (burred dregs of melted metals) emerges inside a cutting surface after laser cutting. Our own dross removing technique can offer clean and smooth cutting surfaces by removing the dross.

[spiral groove processing]

Grooving a NiTi tube with fine laser processing, which is also used for making stents, gives further flexibility to the tube that has originally supper elasticity.

The flexibility and elasticity can be well-controlled in every portion by adjusting the slit width and pitches.

Grooving a NiTi tube with fine laser processing, which is also used for making stents, gives further flexibility to the tube that has originally supper elasticity.

The flexibility and elasticity can be well-controlled in every portion by adjusting the slit width and pitches.

[slit processing (flexible tubes)]

Slits on a tube designed by ourselves make even a NiTi tube with 6 mm inner diameter enable to bend freely. This is an epoch-making product which has excellent operability with its flexibility and pliability as well as strength of NiTi.

Slits on a tube designed by ourselves make even a NiTi tube with 6 mm inner diameter enable to bend freely. This is an epoch-making product which has excellent operability with its flexibility and pliability as well as strength of NiTi.

Bore polishing

Polishing the inside of a tube with 0.3 mm at minimum I.D, 700 mm at maximum length, and Ra 0.1 at minimum surface roughness is available.

(past performance: 0.3 mm I.D., Ra 0.05, and 300 mm long)

(» Click here to see more about bore polishing.)