HOME » Machinery Introduction » Online Factory Tour (Machining centers, CNC automatic lathes, etc.)

Online Factory Tour(Machining centers, CNC automatic lathes, etc.)

Online Factory Tour (Machining centers, CNC automatic lathes, etc.)

update :

Machining & measurement tools in Yage Factory

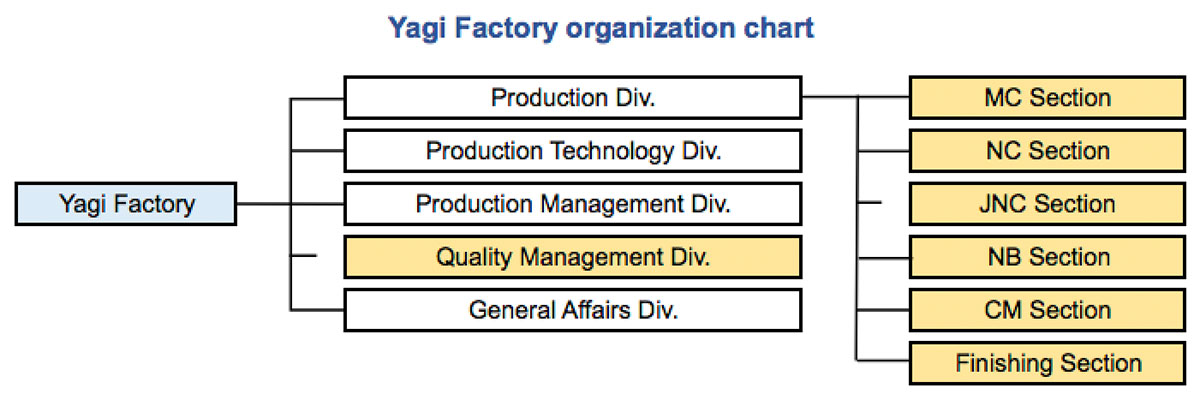

Yagi Factory, our main factory, has about 100 employees.

The production division consists of six sections having the name derived from the machines they are working with. The online factory tour below shows machining and measurement tools working in the production division and the quality management division.

MC Section:

machining centers

This section has 12 vertical machining centers and 7 horizontal ones. They are respectively arranged side by side so that removing or installing a work can be efficiently done during the adjacent machine is working. The number of tools possessed in the section is 64 for vertical machining centers and 48 for horizontal, of which the all are sometimes needed for one work.

NC Section:

numerical controlled lathes, turning centers, and multifunctional machining lathes

This section has 2 turning centers, 12 numerical controlled lathes, and 11 multifunctional machining lathes, totally 25 machines. Many of the finished parts have as the small diameter as of 0.5 mm.

JNC Section: Swiss type automatic lathes

Small parts are made from a long round bar with 20 mm in diameter which is fed into a lathe automatically. The smallest finished work has 0.3 mm in diameter and 1 mm long, cut from a bar with the diameter of 0.8 mm.

NB Section:

CNC automatic lathes

This section has 11 CNC automatic lathes, one of which is equipped with a parts handling robot.

The smallest work has the diameter of 0.5 mm and the length of 0.5 mm. The most challenging work done before was hole drillings of Φ0.28 and 20 mm depth with the finished surface roughness of Ra0.2 on a resin material.

CM Section:

high-precision high-speed minute processing machines

This section has 7 high-precision high-speed machining centers including 4 five-axis machining centers which can process multiple surfaces of a work simultaneously. They are equipped with an automatic lading/unloading robot so that they can operate unmanned for 24 hours. Each operator is working with a product from the beginning to the end of the processes through program making using CAD/CAM system, machine working, process management.

Finishing Section:

Buffing and mirror surface finishing

This process is mainly conducted by hand, which includes cutting, polishing, mirror finishing, sand polishing, blasting, and other hand workings. Burring is done using a microscope.

Quality Management Section:

three-dimensional measurement machine, surface roughness measuring instrument, and circularity measuring instrument

This section is measuring the geometrical tolerances of a product using three-dimensional measurement machine, surface roughness measuring instrument, and circularity measuring instrument. This section is also conducting the inspection and calibration for all the measurement tools in FUTA-Q including each gauge.