HOME » FUTA-Q Technology » Surface Finishing » Teflon ® coating

Teflon ® coating

Teflon ® coating

update :

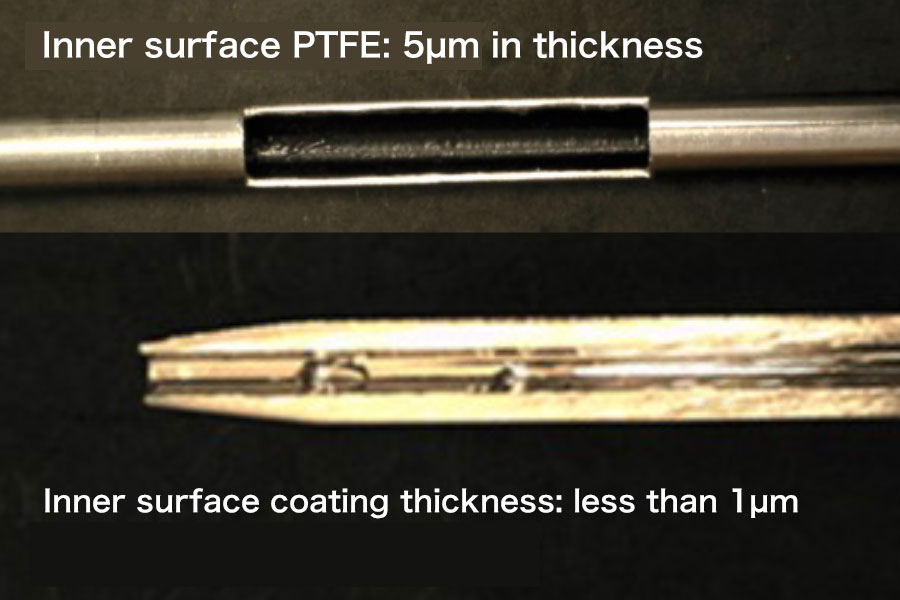

Fluorine coating technology for nozzle’s inner surface

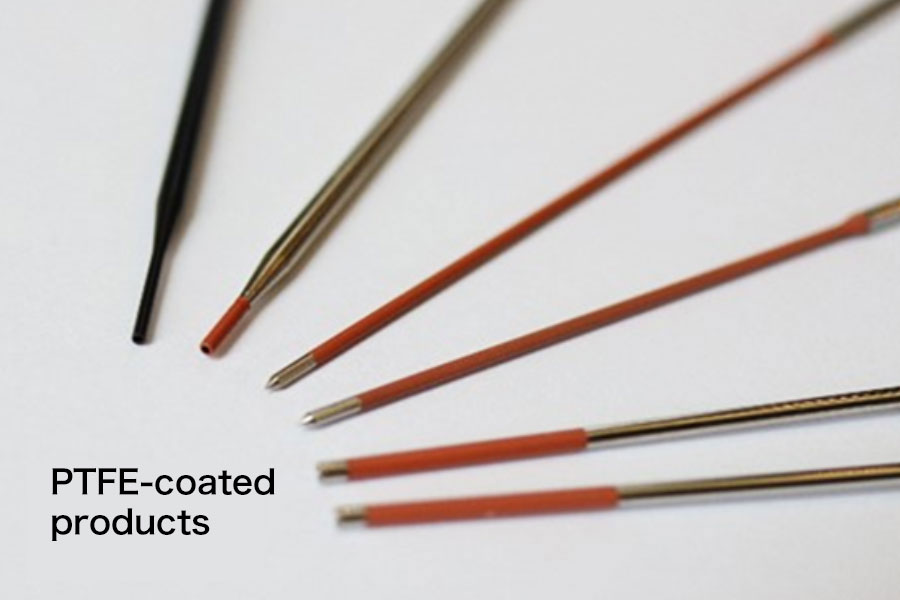

The fluorine coating is used for the nozzles for medical or analytical instrument which are required to be abrasion resistant and have the ability to prevent dirt from sticking to them.

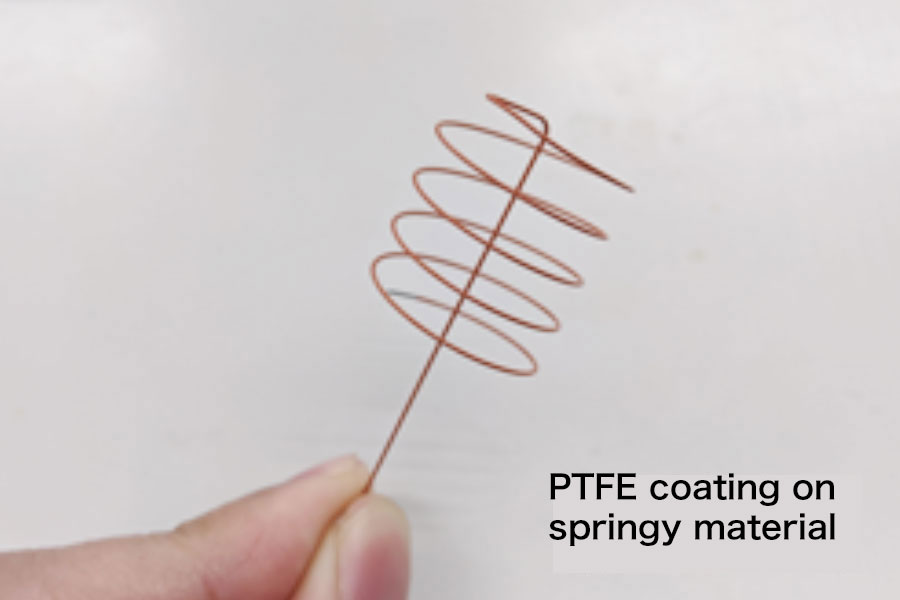

For its good adhesion property, this coating is also used for springy materials or products that require insulation properties.

FUTA-Q own processing equipment and coating agents that can conduct fluorine coating to the inner surfaces of small-diameter pipes. This coating can be conducted from prototyping to mass production.

Effect of fluorine coating

– Water repellency

t is a property that repels water well, making it difficult for dirt to adhere to the surface, reducing contamination, and making it easier to remove adhered dirt by washing. This performance is expressed in terms of “contact angle.” The higher the value, the better the water repellency, and the more rounded a drop of water on it becomes.

– Abrasion resistance

Abrasion always occurs when a product comes in contact with a mating part or roll on it.

The abrasion resistance of coatings is evaluated based on the abrasion resistance test method of plating defined by JIS.

– Coefficient of friction

Fluorine coatings have a low coefficient of friction and slippery property.

Applying the coating results in reducing friction on the surface of a product, which makes the surface scratch-resistant and its service life longer.

Example of PTFE coating on nozzle O.D./I.D.

This highly difficult machining technique uses highly water-repellent, highly insulative PTFE coating on the internal and external surfaces of the pipes. This coating technology facilitates reliable and accurate analysis work.