HOME » FUTA-Q Technology » Precision and Microfabrication » Ceramic microfabrication

Ceramic microfabrication

Ceramic microfabrication

update :

What is Ceramic?

Originally, this means forming natural materials such as clay and burning them in a fire.

Traditional ceramics include ceramics, glass and cement.

As a result of scientific advances, new ceramics containing oxides, metal compounds, carbon alloy, etc. were born.

New ceramics are produced by controlling the chemical structures, compositions, and organizations of materials.

It has advanced or unique characteristics.

Ceramic micro-processing technology used in advanced medical treatment

Healthcare components require smaller and tougher materials.

The demand for ceramic minimal components as well as titanium and nickel has been increasing.

We have implemented dust-proof measures for high-precision micro-processing machines to perform ceramic processing,Through the evolution of medical devices, we are playing a role in contributing to society.

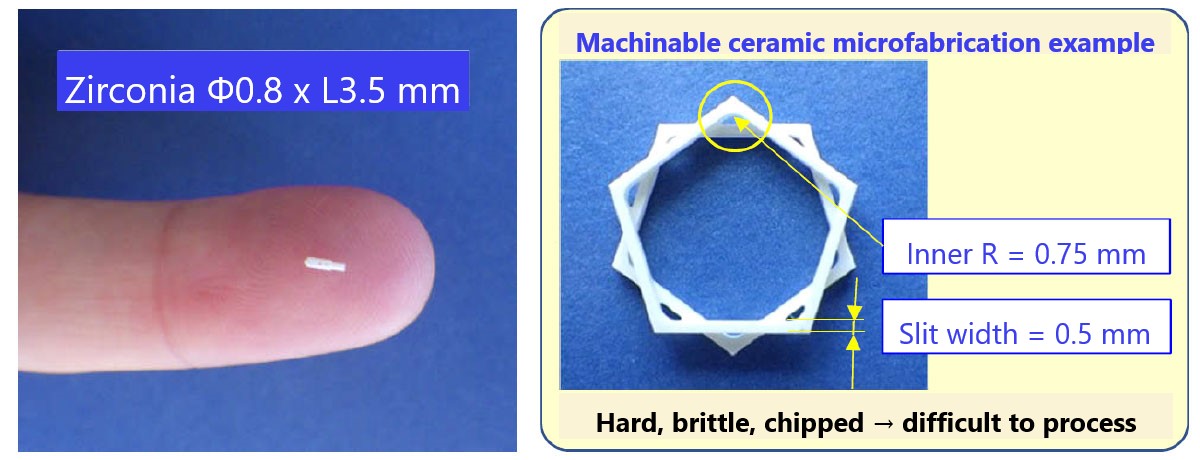

Ceramics are more fragile and easier to chip than resins and metals.So optimization of tools enables machines to process more accurately.

Micromachined components used in medical devices

Making use of zirconia’s electrical insulation, it is used in the latest medical treatment devices.

Specifications of high-precision fine processing machining center

- ・For sufficient dust proof measure for Ceramic procesing is implemented.

- ・High-speed spindle speed: 40,000rpm

- ・Machining jig replacement accuracy: 1 μm (actual value)

- ・Number of tools set: 20

- ・Position can be corrected by measuring the engineering sensor.

Measures have been taken to prevent wear of sliding parts due to ceramic processing powder.