HOME » Machinery Introduction » Finishing Machining Equipment

Finishing Machining Equipment

Finishing Machining Equipment

update :

The list of our finishing machining equipment

| Equipment | Features | Notes |

|---|---|---|

| Shot blasting machine | Polishing agent such as alumina particle ejected from a nozzle with compressed air hits a product surface to smoothen the surface. | Please refer to the following A. |

| AERO LAP machine (Mirror polishing device) |

This works on the same principle with that of a shot blasting machine. Mirror finishing can be done using special wet polishing agent. |

Please refer to the following B. |

| Centrifugal barrel polishing machine | A plurality of barrels making planetary motion polishes works by giving them high pressure and speed. | Please refer to the following C. |

| Rotary barrel polishing machine | The works put in a rotating barrel with polishing agents are polished by rubbing each other. | Deburring for metals |

| Buff polishing machine | A buff, a bundled rag, applied with polishing agent is pressed against a rotating product surface to polish it. | For making mirror finished surface |

A. Shot blasting machine

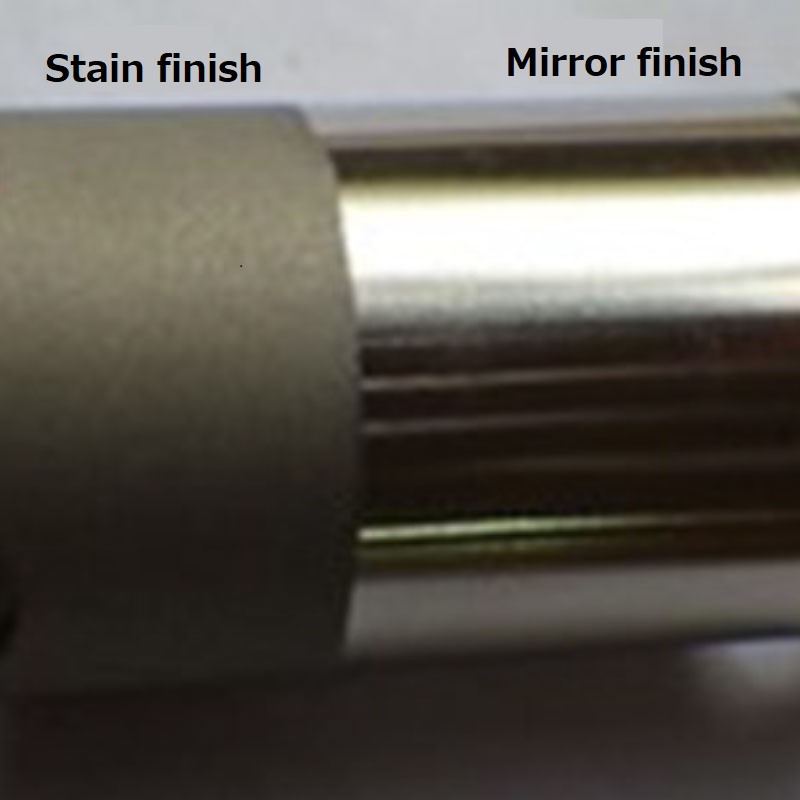

By using a different kind of polishing agents, this can be applied to a wide range of applications such as deburring, scale removal, surface roughening. The left half of the photo below is finished as a pear-skin shape while the right half having a mirror surface is masked.

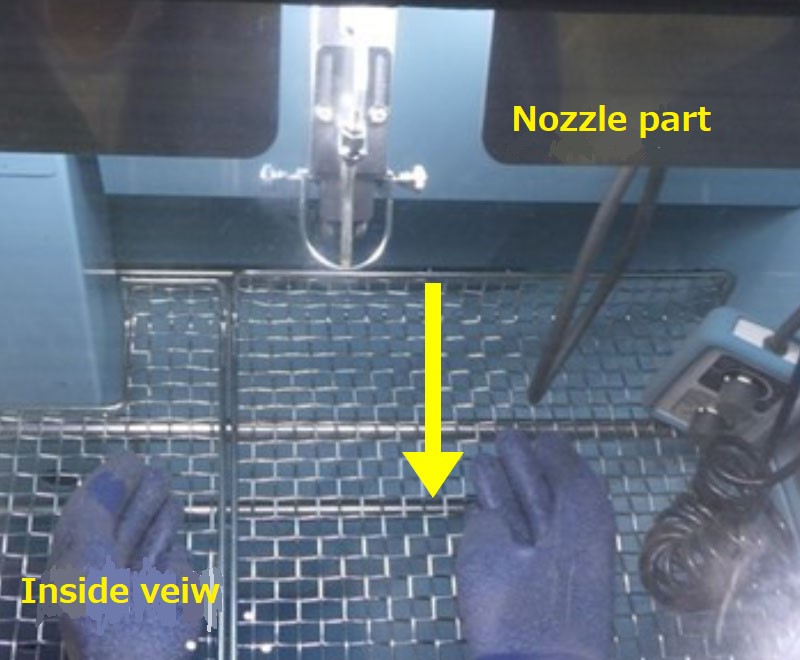

B. AERO LAP machine (Mirror polishing device)

Buff polishing leaves small scratches on the finished surface. For a product requiring a mirror surface or having a complex shape, the AERO LAP machine is used.

C. Centrifugal barrel polishing machine

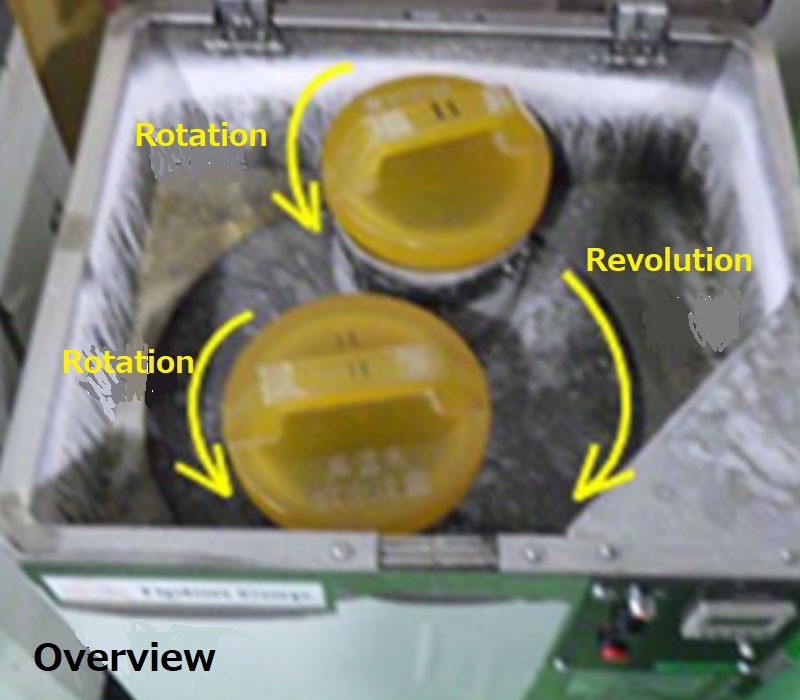

Products are put into the barrel with abrasive grain, a liquid, and a polishing powder. The barrel rotates while the bottom plate where the barrel sits on revolves. By using a different kind of abrasive grain, this can make a surface with various roughness from a rough one to a glossy one.