HOME » Machinery Introduction » Machinery Introduction

Machinery Introduction

Machinery Introduction

update :

Manufacturing Facilities in Yagi Factory

If you are viewing on a smartphone, you can scroll the table horizontally.

| Manufacturing Facilitiy | stroke (mm) | Maximum workable size | number | ||

|---|---|---|---|---|---|

| X-axis | Y-axis | Z-axis | length or diameter | ||

| Machining center | 762 | 430-460 | 450-460 | Vice mouthpiece full-open dimensions ~130m/m |

10 |

| Horizontal machining center | 560-762 | 560 | 460-625 | 8 | |

| High-speed fine processing machine | 410-510 | 330-410 | 160-200 | diameter : 110 mm – 195 mm Y-axis : 195 mm X-axis : 300 mm – 410 mm |

7 |

| 5-axis processing machining center | 300 | 300 | 300 | diameter : 90 mm | 1 |

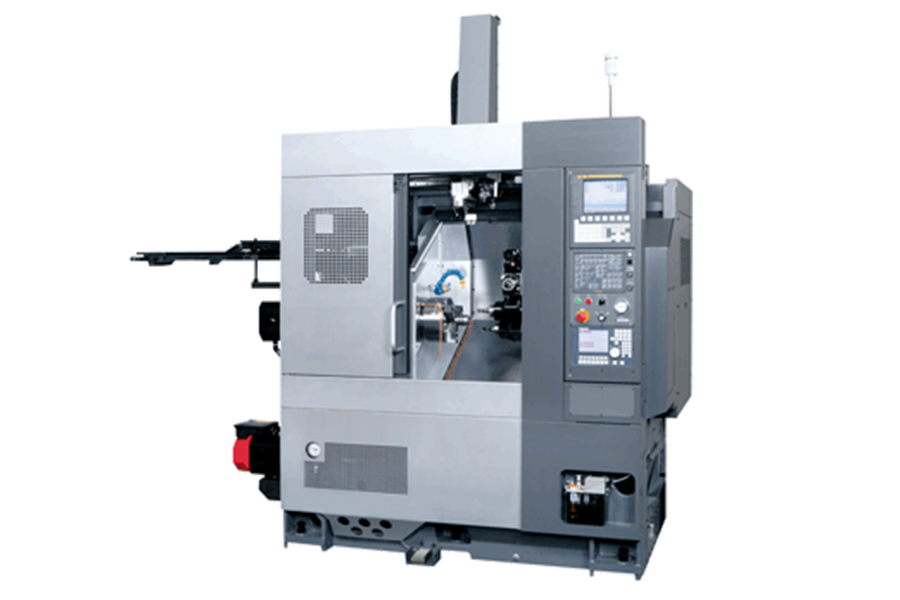

| Combined CNC lathe | 120-560 | -150-150 | 130-1000 | diameter:175 mm – 540 mm 棒材φ4~φ65 bar material diameter:4 mm – 65 mm material length:1m -3m |

21 |

| CNC lathe | 50-200 | 100 | 85-370 | diameter : 135 mm – 280 mm diameter : 11 mm – 20 mm |

22 |

| Wire-electrical discharge machine | 600 | 400 | 310 | 1 | |

Manufacturing Facilities in Kyoto factory

| Manufacturing Facilitiy | moving sphere(mm) | notes | number | ||

|---|---|---|---|---|---|

| X-axis | Y-axis | Z-axis | |||

| Laser cutting and welding instrument | 480 | 350 | 600 | average 250 W | 1 |

| Laser instrument | 300 | 250 | 200 | average 35 W – 100 W | 3 |

| Laser cutting instrument | 300 | 4 | 12 | length 2000 mm | 2 |

| Aero lapping instrument | 450 | 300 | 240 | precise blast processing | 1 |

| Pipe-making instrument (Three rolls, Drawbench) |

ー | ー | ー | ー | 3 |

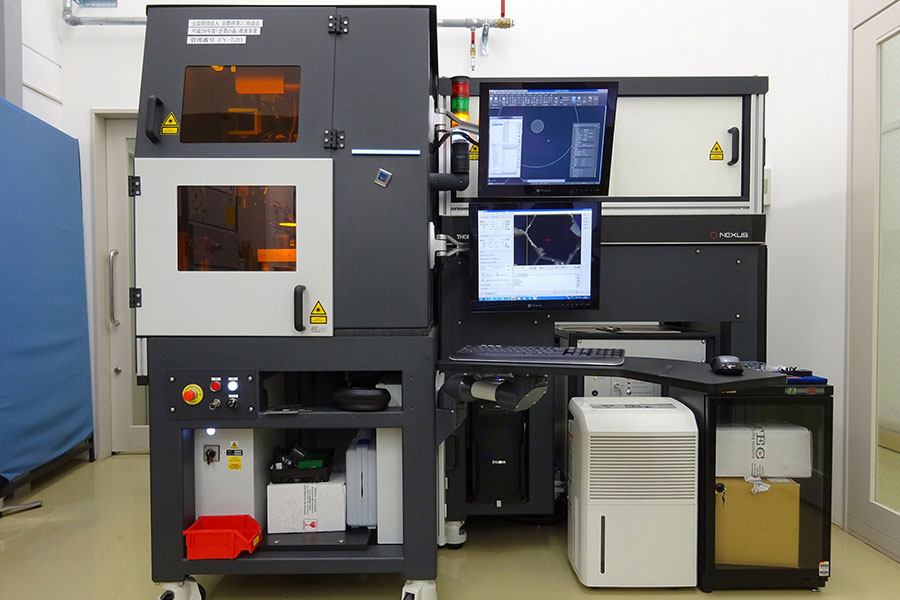

| Femto-second laser machine | – | – | – |

ultra short pulse laser processing very little heat influence |

1 |

| Scanning electron microscope (SEM-EDS) |

– | – | – | Surface analysis is available. | 1 |

| Centerless grinder | – | – | – | 1 | |

Measuring tools

| Measuring tool | Measurable size (mm) | notes | number | ||

|---|---|---|---|---|---|

| X-axis | Y-axis | Z-axis | |||

| CNC vision measuring system | 200 | 200 | 300 | length (side, angle, circle) roundness, flatness, parallelism straightness, positional tolerance concentricity, symmetry |

1 |

| Three-dimensional coordinate measuring machine | 700 | 700 | 600 | “flatness,roundness, squareness cylindricity et al.” |

1 |

| Surface texture and contour combined measuring instrument | 200 | ー | 13 | circle shape, pitch, angle et al. | 1 |

| Circularity measuring equipment | 180 | ー | 300 | “roundness, concentricity, cylindricity, squareness, runout” |

1 |

| Vision measuring system | 100 | 100 | 75 | flat coordinates measurement length (side, angle, circle) roundness, parallelism, straightness positional tolerance, concentricity |

2 |

| Measuring microscope | 300 | 200 | 200 | flat coordinates measurement with arithmetic function |

2 |

| Tool microscope | 150 | 100 | 200 | plane coordinates measurement | 1 |

| Durometer | ー | 100 | ー | hardness measurement | 1 |

| Shape analytic laser microscope | 300 | 300 | 70 | “shape measurement surface roughness” |

1 |

| Projector | 50 | 50 | ー | “length, angle (vernier scale) measurement with shade” |

1 |

| Microscope | ー | ー | ー | shape measurement | 1 |

| Breakage inspection instrument | ー | ー | ー | tension ability : 2 tons (measurable material diameter : 0.5 mm – 9 mm) |

1 |