HOME » FUTA-Q Technology » Materials for small diameter pipes (β-titanium, NiTi, stainless-steel, ELGILOY, MP35N) » SUS Pipe (Stainless Steel)

SUS Pipe (Stainless Steel)

SUS Pipe (Stainless Steel)

update :

What is SUS (Stainless Steel)?

Alloy with iron (Fe) as the main component and hard to rust, including chromium (Cr)

Stainless steel is a well-known metal, which is often used for kitchen goods, because of its clean, glossy and rust-resistant features.

Especially because of its excellent corrosion resistance, it is increasingly being used for food processing equipment, medical equipment, and analytical instruments.

Corrosion resistance of iron (Fe) improves as increasing chromium content increases, and especially steel with chromium added at least 12% is called stainless steel.

The reason why iron (Fe) is not rusted is that chromium (Cr) is easily oxidized, and the stainless steel surface is covered with an oxide film of chromium (Cr) to prevent the oxide reaction within the metal.

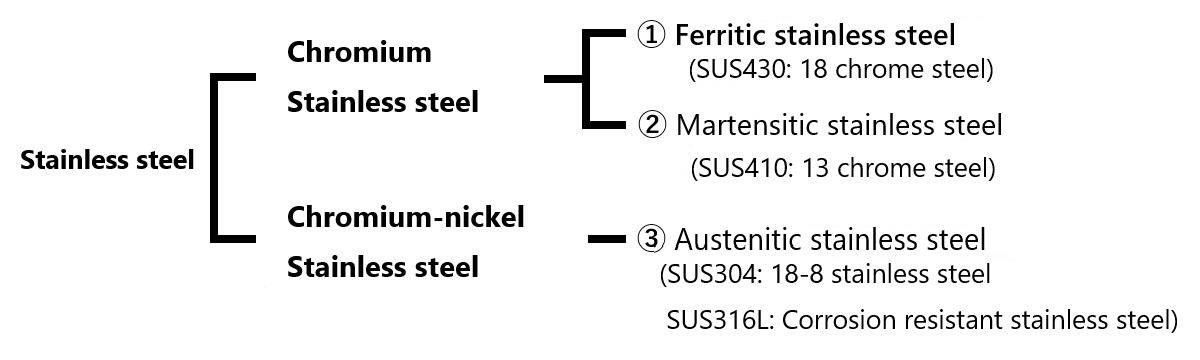

Stainless steel can be broadly classified as follows

FUTA・Q mainly handles “③ Austenitic stainless steel.”

Steel with excellent corrosion resistance, workability, formability, and weldability, high strength at high temperature, and toughness even at low temperatures, is used in a wide range of fields, including household goods, automotive parts, chemical industry, food processing, and medical equipment.

What is the difference between SUS that sticks to magnets and SUS that doesn’t?

Typical stainless-steel SUS304 generally does not stick to magnets.

However, it is mistakenly said, “Stainless steel cannot be attached to magnetic materials.”

Broadly speaking,

”Austenitic stainless steel does not stick to a magnet”

”Other stainless steel sticks a Magnet”

And so on.

The stainless steel surface is covered with an oxidized non-conductors coating (chromium oxide coating), and this non-conductors coating is non-magnetic.

Nickel (Ni) also has a magnetic anisotropy, and it has a property of rubbing the magnetic direction from the direction of the nickel crystal inside the austenitic stainless steel, so it does not stick to a magnet.

Will the stainless steel be bent into martenite and attached to the magnetic material?

When external force is applied to austenitic stainless steel, it becomes martensitic.

When bending or other forming processes are performed, the processed portion becomes martensitic and becomes magnetic, sticking to the magnet.

Just the name of the material cannot distinguish whether it is non-magnetic or not.

A variety of stainless steels handled in FUTA・Q:teatures and compositions.

| Name | Component | Characteristics |

|---|---|---|

| SUS304 | 19Cr-9.3Ni | It is most commonly used as heat resistant steel. Good corrosion resistance, weldability and mechanical properties |

| SUS303 | 18Cr-9Ni | It is called free-machining stainless steel, and it has high cutting and anti-fire properties by adding sulfur and rin. The corrosion resistance is inferior to the SUS304. |

| SUS316 | 17Cr-12Ni-2.5Mo | Molybdenum (Mo) is added to improve corrosion resistance and pitting corrosion resistance over SUS304. |

| SUS316L※ | 17Cr-12Ni-2.5Mo | In addition to the properties of 316, the ultra-low carbon steel with low C content further improves intergranular corrosion resistance. |

※ L stands for Low carbon.

Why is SUS316L more corrosive-resistant?

We explained that stainless steel has a passive film (chromium oxide film) on the surface which prevents the surface from rusting.

However, when the product is exposed to a high-temperature atmosphere of about 650°C, chromium carbonate (Cr23C6) is generated, and the chromium oxide film is partially eliminated, resulting in some unprotected areas where protection is not possible.

This phenomenon is called intergranular corrosion.

As a countermeasure against intergranular corrosion, reducing carbon to less than 0.03% resulted in more corrosion-resistant SUS316L stainless steel.

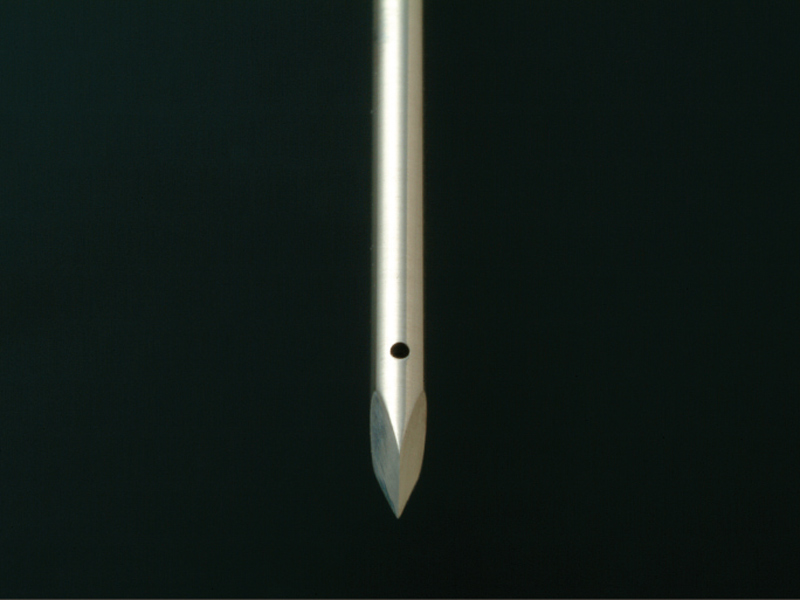

We sell offer a variety of products with SUS pipes,for a variety of fields, including analytical equipment, semiconductor-related equipment,

and automation equipment,with a focus on medical equipment

We combine various precision processing technologies to meet customer needs.