HOME » FUTA-Q Technology » Surface Finishing » F2901 (Water/oil Repellent Fluorine Coating)

F2901 (Water/oil Repellent Fluorine Coating)

F2901 (Water/oil Repellent Fluorine Coating)

update :

Metal surfaces have originally high affinity for liquids such as water, alcohol, and oil. A drop of water, for example, can easily spread over an alcohol-wetted metal surface. F2901 coating forms a fluoric thin film on a metal surface to keep possible-fouling made by water, oil and any other contaminations off the metal surfaces.

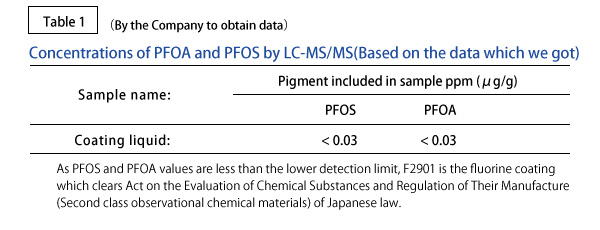

PFOA (perfluorooctanoate) and PFOS (perfluorooctane sulfonate) are an artificial organofluorine compound containing fluorine. They are water-soluble compounds that can be accumulated in human bodies. The EU regulation set up the different regulation values per material, surface treatment and product category. The table below shows the concentrations of PFOA and PFOS in F2901 measured by LC-MS (liquid chromatograph mass spectrometer and MS (Mass spectrometer), which are obviously below the EU regulation limits.

The effectiveness of F2901 coating.

The liquid dripping from the nozzles is alcohol. Without F2901 coating, the alcohol is sticking around the nozzle surface so that the droplets from the nozzle are dripping along the outer surface of the nozzle. (Left)

The droplets from the coated nozzle never stick around the nozzle tip, forming a beautiful granulated shape due to the great water/oil repellency of F2901 coating. (Right)

Coating the inner surfaces of nozzles with F2901 can improve their water/oil repellency so that the residual accumulated therein can be easily removed by air blowing. This also improve the rinsing efficiency, resulting in the decrease of contaminations inside nozzles.