HOME » FUTA-Q Technology » Welding » Laser welding

Laser welding

Laser welding

update :

FUTA-Q is equipped with YAG laser and fiber laser and several laser welders differing in spec. to meet various requirements.

Laser welding has a narrow width with respect to depth, enabling welding with high penetration efficiency.

In particular, continuous welding with a fiber laser machine can also produce smooth welded surfaces without overlap.

Features of Laser Welding Machines

| FUTA-Q-owned laser welding machines | Micro precision laser welding machine (fiber laser) | Seamless precision laser welding machine (fiber laser) | High-intensity precision laser welding machine (YAG, fiber laser) |

|---|---|---|---|

| Main features | Finely tunable of the minimum processing diameter and laser energy | Continuous, deep welded area | High-strength welding with high precision and productivity |

| Main applications | Processing of intravascular medical device parts made of ultrafine wire, etc. | Processing of high- performance gas piping components, etc. | Processing of precision nozzle parts, etc. |

| Laser wave length | 1070nm | 1070nm | 1064 nm in YAG 1070 nm in fiber |

| Minimal material outer-diameter | Φ0.05 mm | Φ3 mm | Φ0.2 mm |

Primary Applications

Medical device applications

Medical device applications (typical workpiece size: Φ0.05 mm – Φ0.5 mm)

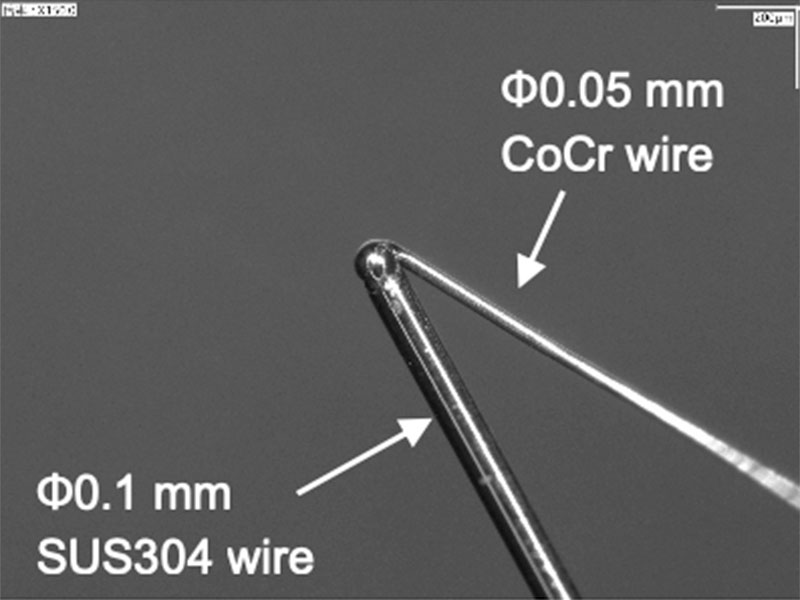

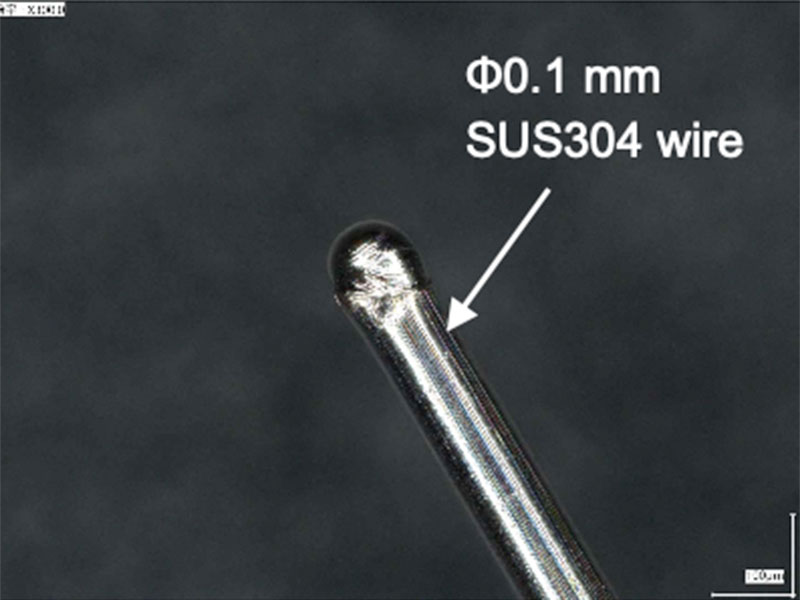

Producing components for medical devices using extremely thin wires, pipes, and odd- shaped parts requires to have reliable laser welding as well as edgework to ensure that the laser-processed ends never damage blood vessels.

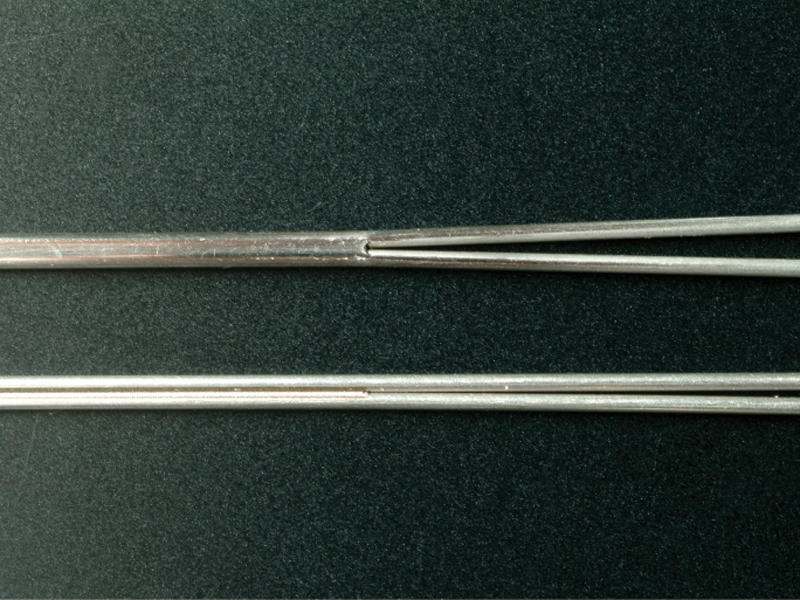

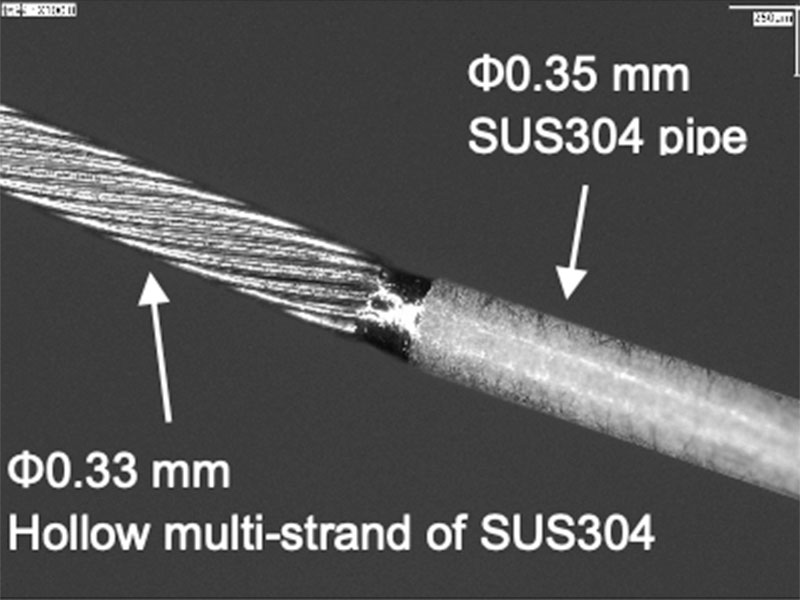

Welding of SUS304 hollow multi- strand coil (Φ0.33 mm) and SUS304 pipe (Φ0.35 mm)

Welding of CoCr wire (Φ0.05 mm) and SUS304 wire (Φ0.1 mm)

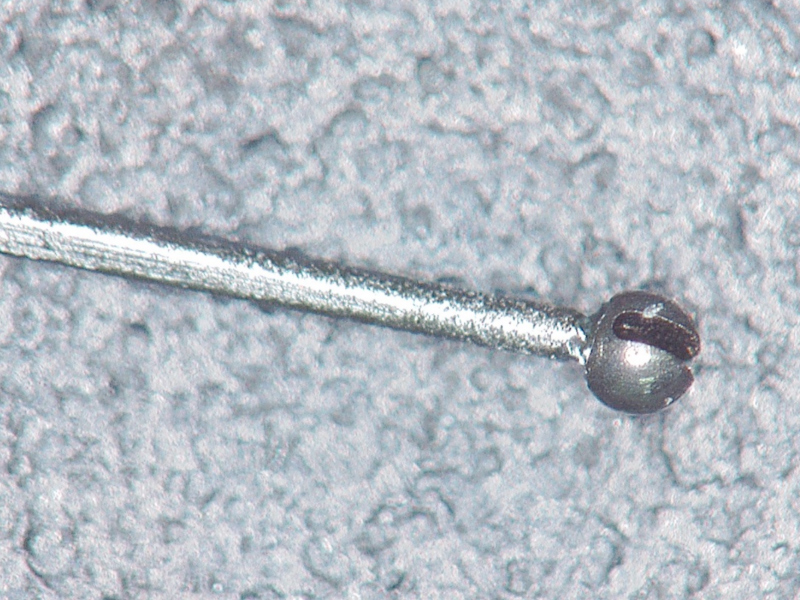

End treatment of SUS304 wire (Φ0.1mm)

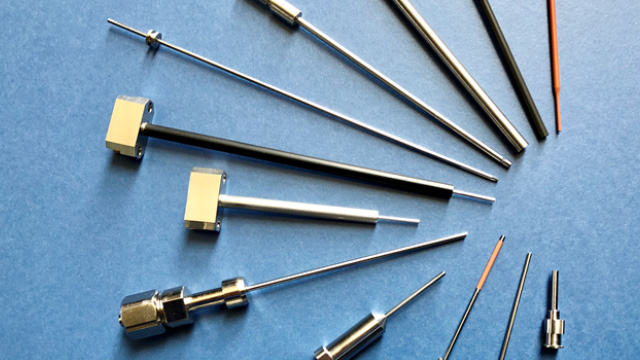

Nozzle and needle applications

Nozzle and needle applications (typical workpiece size: Φ0.5 mm – Φ5 mm)

Accurate and reliable laser welding are required for making nozzles and needles used in blood analysis and state-of-the-art production equipment.

A precision holed machining part is welded to a pipe end

A SUS304 machined part is welded to a SUS304 pipe (Φ1.6mm OD) pipe

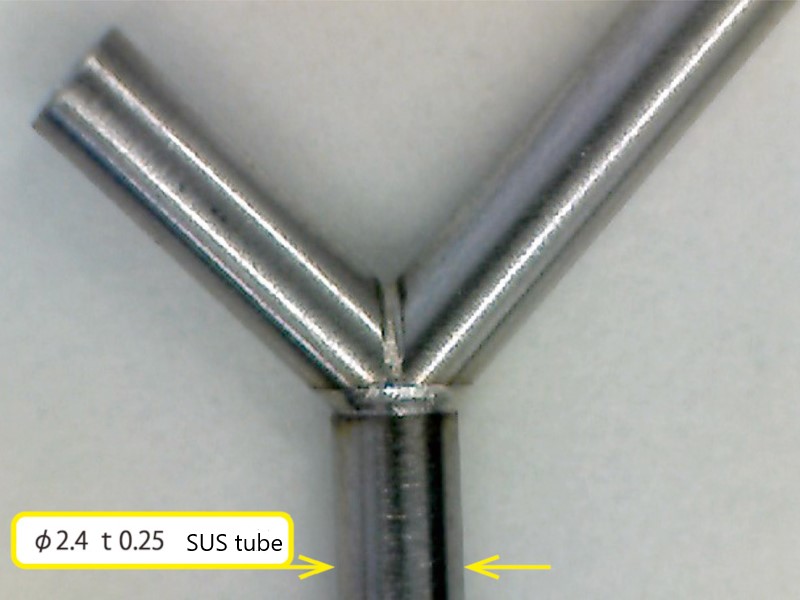

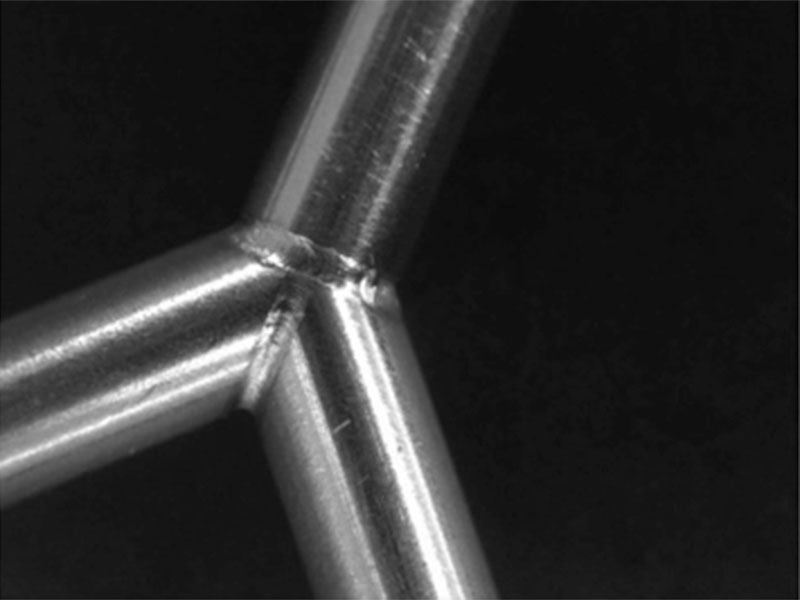

Three SUS304 pipes (Φ2.4 mm OD and Φ2.3 mm ID) are welded together into a Y-shaped branch pipe

Applications of Laser Processing

By combining pattern cutting and drilling by laser processing with laser welding and assembly, various shapes and functions can be added to the product.

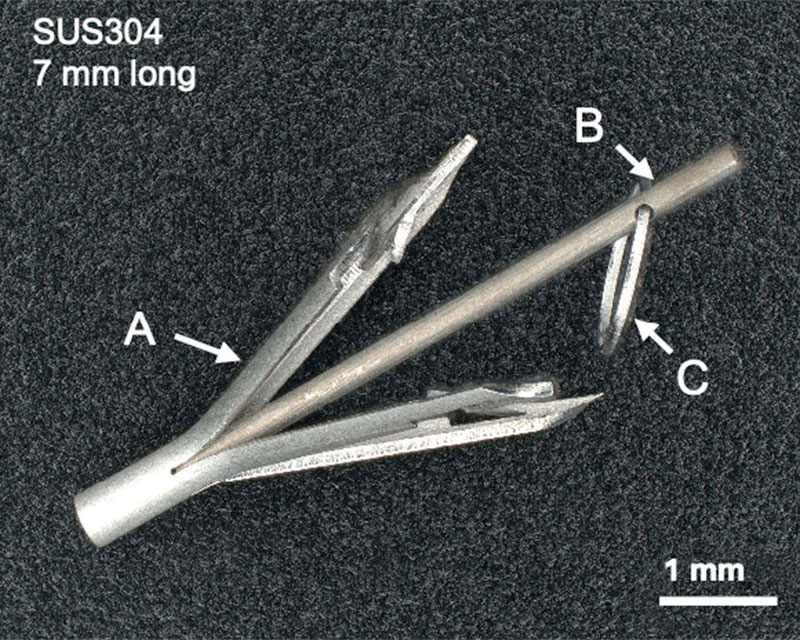

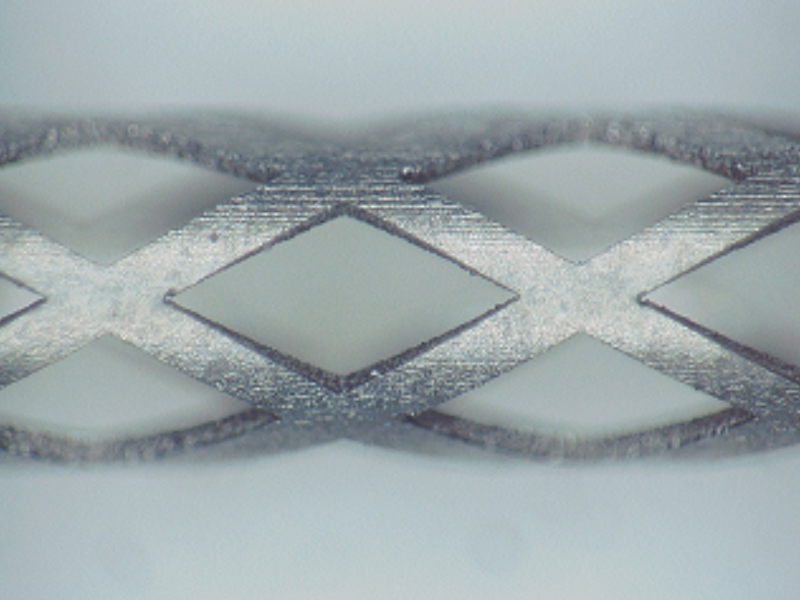

Processed products with combination of laser-cutting and laser-welding

SUS304 product with length of 7 mm.

A. Laser pattern cutting on SUS pipe of Φ0.51 mm OD

B. Laser hole drilling on SUS wire of Φ0.26mm OD

C. Circular processing SUS plate of 0.1 mmthick

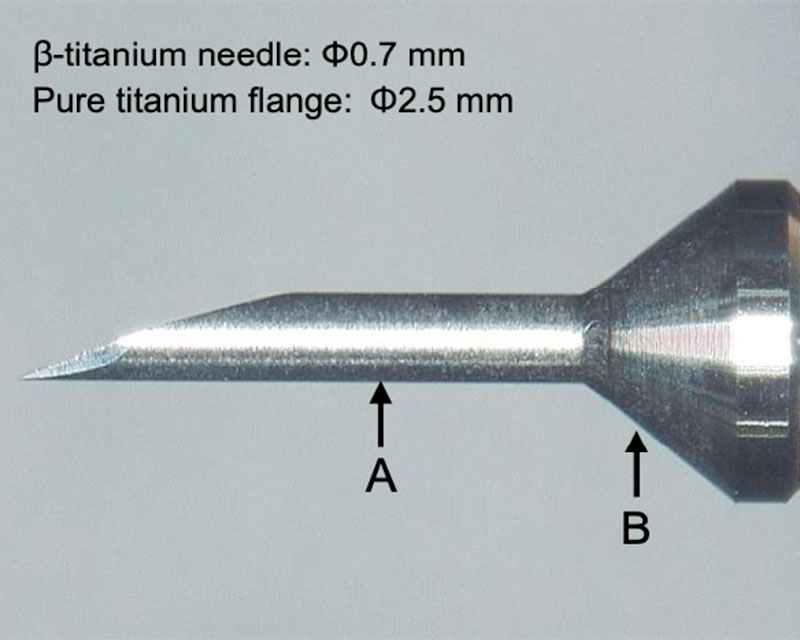

This product is manufactured by a combination of bending and laser welding.

Titanium alloy product with length of 5 mm.

A. Needle tip forming by laser cutting on a β-titanium pipe of Φ0.7 mm OD

B. Processing a pure titanium of Φ2.5 mm OD into a flange using a CNC lathe

These parts are joined by laser welding.

Laser micro welding technology

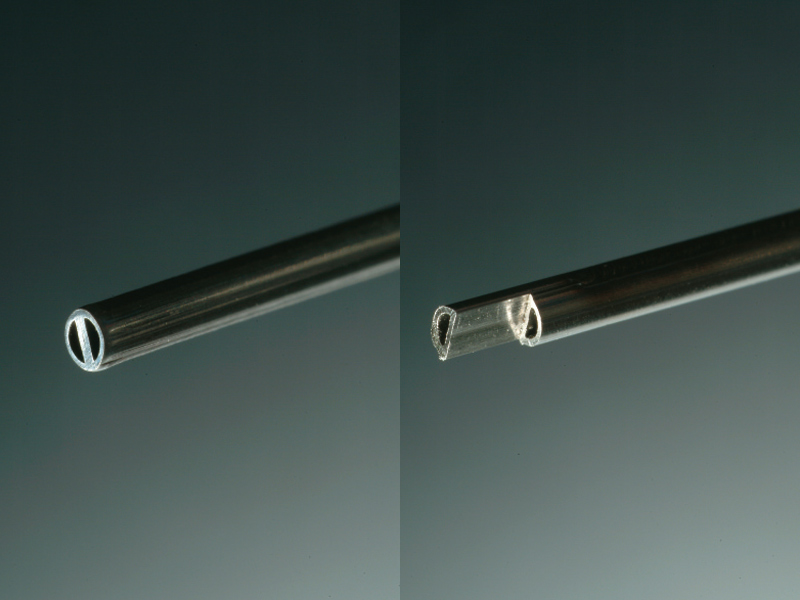

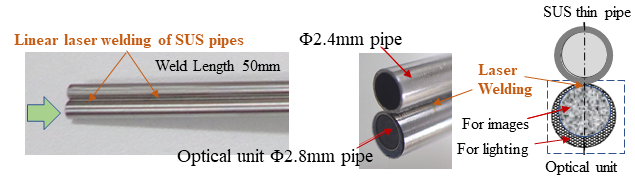

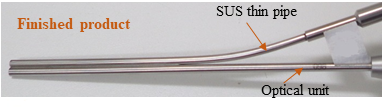

This section introduces the joining technology of laser welding of small diameter pipe for optical unit and thin SUS pipe.

Laser welding of thin-walled small-diameter pipes is easy to damage parts, and it can be finally realized by the ingenuity and depends on the skill of a technician who is familiar with the equipment.

[Welding process]

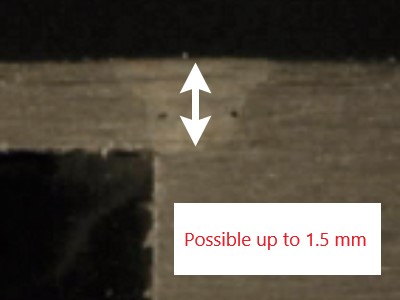

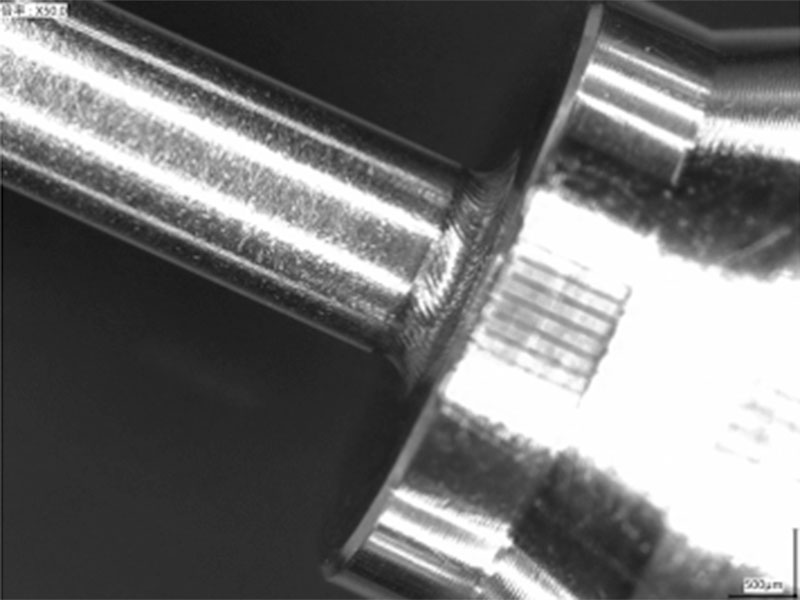

Laser welding is performed by linearly arranging SUS thin-walled pipes in the upper part of the optical unit pipe.

[Difficulty]

① Inside the pipe are Optical fibers for illumination and image,

are inside the pipe, So it heat distortion occurs during welding,it may affect the photographed image.

② I want to finish out a clean outline of the pipe.

Initiatives and Points for Realization

① In small-diameter pipe welding using a laser beam machine, the laser beam width becomes narrower and penetrates deeper,

Welding conditions must be set to avoid damaging the optical fibers.

② To make a fine, smooth and linear welding beam on a pipe machined surface.

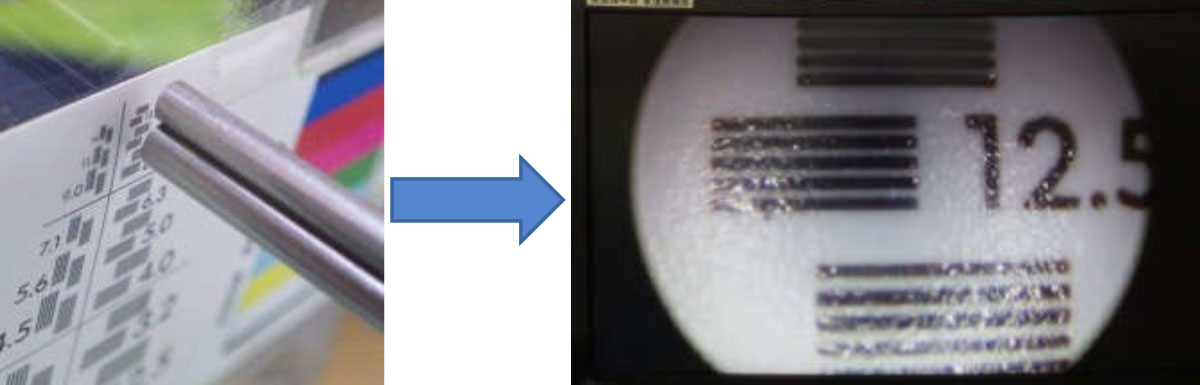

Evaluation after welding

① The beam of the laser weld produced a beautiful finish.

② As a result of the photographing image confirmation of the optical unit, the effect by the heat caused by the welding was not observed.

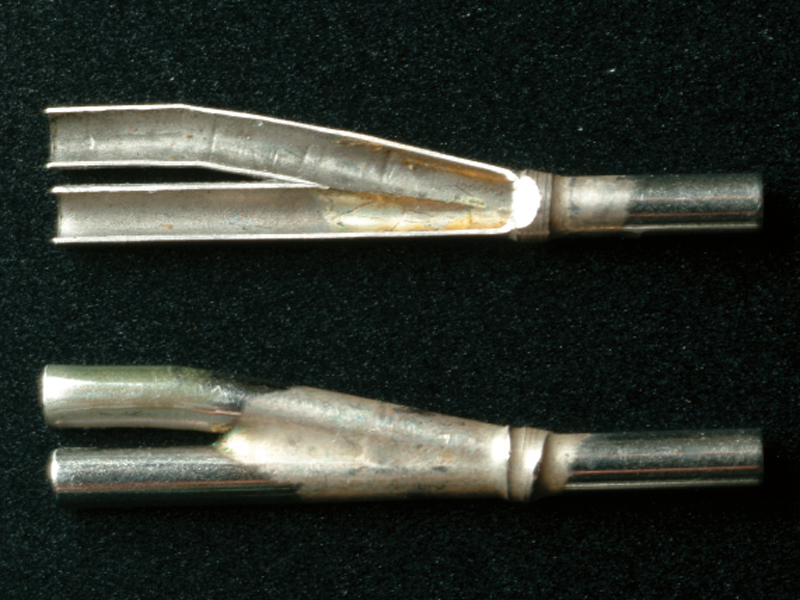

Laser Welding of Two Half-Month Pipe

It is a technique for joining narrow pipes with injection needles, and the features do not have a conspicuous weld area. It is mainly used for hollow needles that absorb samples, and is ideally suited for products that require a 2WAY function of sending air from one of the pipes and absorbing samples from the other pipes. Various materials and shapes are available.

Y-shaped branch pipes of thin pipes (φ2.4×t0.25)

Laser welding is suitable for welding thin-walled pipes. A Y-shaped branch pipe has been completed by combining laser welding machines with cutting technologies.

Laser Welder Features

• Laser diameter minΦ0.016-

• Up to a weld depth of 1.0mm

• X-axis, Y-axis, and rotation directions can be moved.

• Fine spot welding is available

Frequently Asked Questions About Laser Welding and Contract Processing

- Can you handle parts for medical devices?

- Yes, we have extensive experience processing parts for medical device applications.

We have experience working with medical-grade high-performance metals, including stainless steel, titanium alloys, CoCr alloys, and Pt alloys. - How fine a wire can you laser weld?

- We have experience laser welding wire as fine as Φ0.05 mm.

- What effects can welding have?

- Depending on the material, effects such as reduced weld strength may occur due to oxidation or the formation of intermetallic compounds.

Even when issues arise, improvements can often be achieved by optimizing part configuration, processing geometry, or processing methods.

Pages Related to Laser Welding and Processing

Related Pages on Laser Welding and Contract Processing

-

Welding

We offer the most suitable joining techniques based on material, shape, and purpose, including TIG welding for thick materials, laser welding for thin and micro components, and traditional joining methods such as brazing.

-

Laser Processing

From ultra-fine processing at 10μm, designed pattern cutting, laser welding, to UV marking. We have various laser processing machines optimized for each product type, including ultrashort pulse lasers capable of processing glass.

-

Nozzles, Needles & Pipes

FUTA-Q’s strength lies in its ability to design, process, and assemble a wide variety of special fine tubes in-house. We have extensive experience with stainless steel pipes as well as β-titanium, NiTi titanium, cobalt alloys, and more.