HOME » FUTA-Q Technology » Precision and Microfabrication » Titanium Micro Processing

Titanium Micro Processing

Titanium Micro Processing

update :

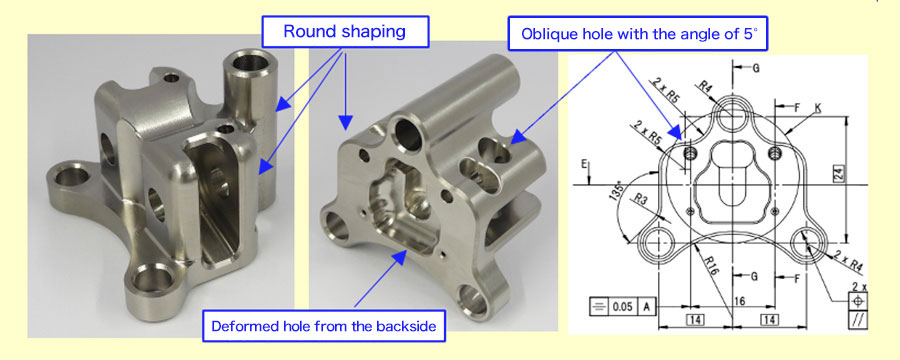

High-precision Five-axis Machining

Material: Pure titanium (JIS second grade), a hard-to-machining material having high corrosion resistance and low thermal conductivity,

Size: 32 x 28 x 25 mm

Holes: five of 5 mm, two of 0.8 mm, two slant holes with 5° of 2 mm in diameter Surface roughness: Ra 0.8 (0.8 μm)

Titanium medical parts

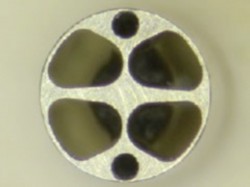

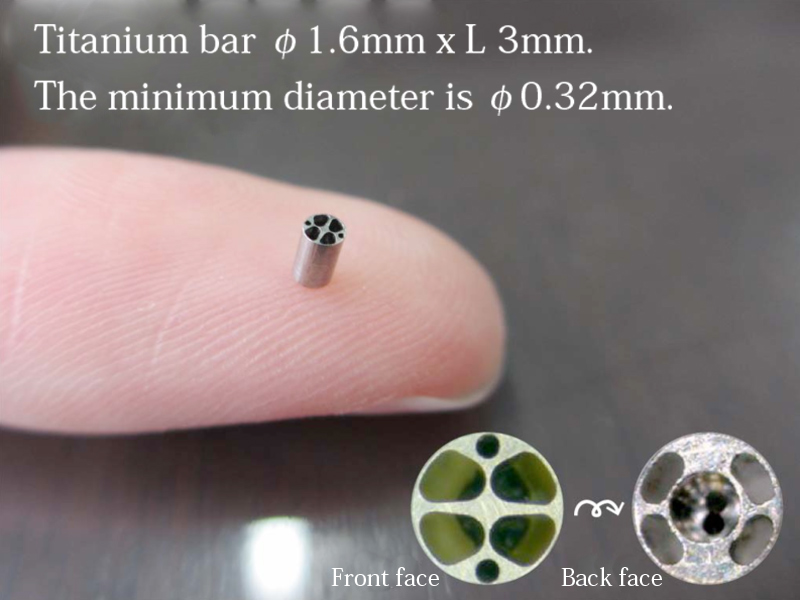

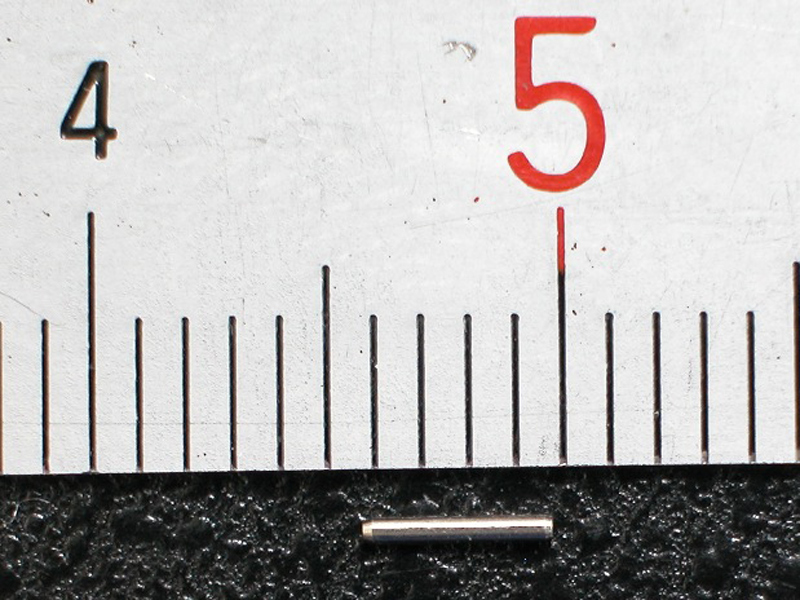

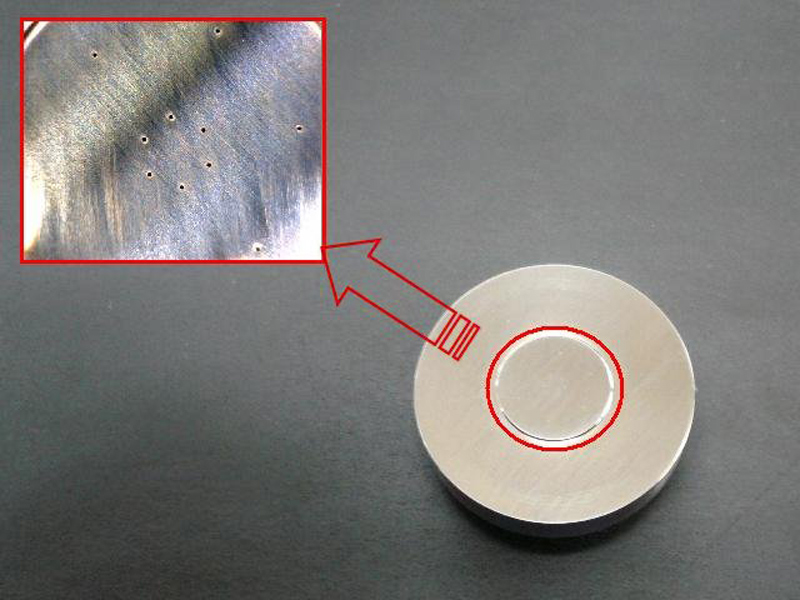

Taper shaped holes are formed by helical boring from the both ends of a titanium bar having 1.6 mm in diameter and 3 mm long. The holes show different shapes from each other ends, having a diameter of 0.32 mm at the smallest area and are formed only by cutting process.

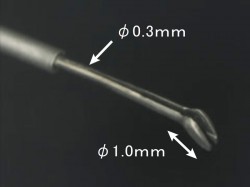

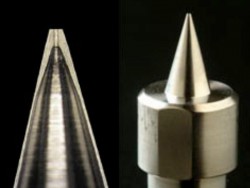

Micro forceps

We have succeeded in producing a micro forceps made of titanium for medical surgery with our mono-block cut-out technique. The forceps feature its extremely small size with the shaft diameter of 0.3 mm and the tip diameter of 1.0 mm. Anti-corrosive characteristic of titanium and our improved accurate machining techniques enable a surgeon to conduct more precise operations.

[Video clip of micro forceps]

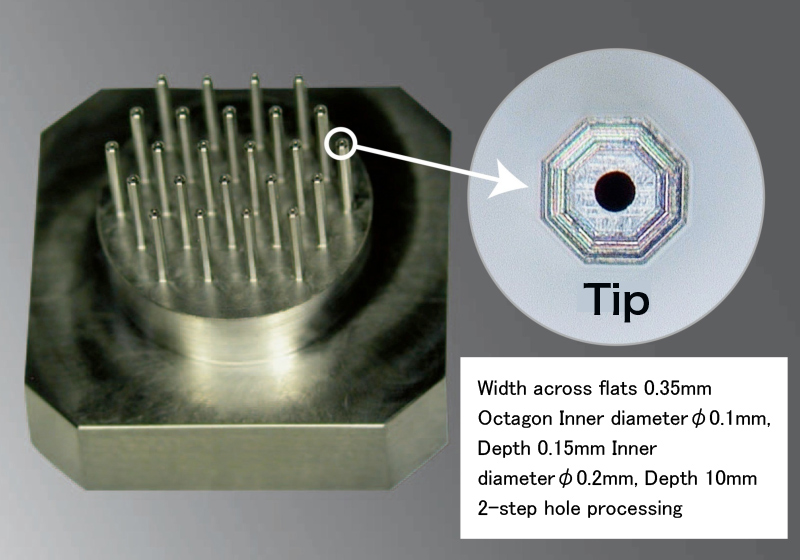

Mono-block titanium nozzle

Material: DAT51 (β-titanium alloy made by Daido Steel Co., Ltd.)

This nozzle block is shaved out from one block of β-titanium, having elasticity, high flexural rigidity, and corrosion-resistance properties.

Nozzles: Octagon shape with the width across flats 0.35 mm, and a stepped hole having ID of 0.1 mm and 0.15 mm deep, and ID of 0.2 mm and 10 mm deep