HOME » FUTA-Q Technology » laser processing » Laser processing|Metal precision microprocessing

Laser processing|Metal precision microprocessing

Laser processing|Metal precision microprocessing

update :

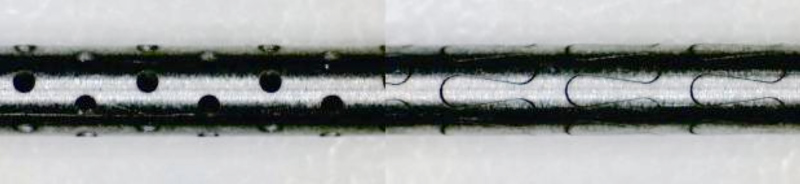

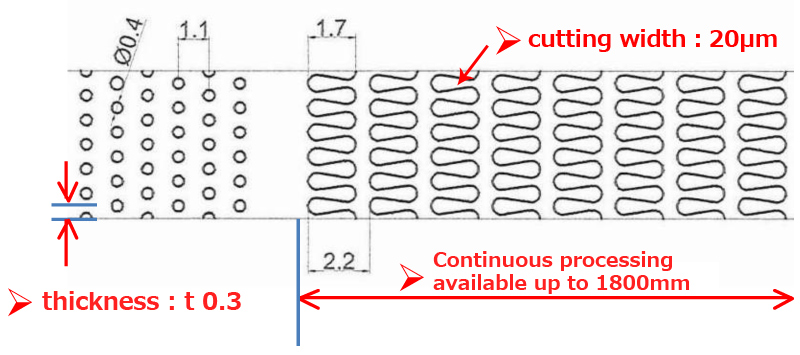

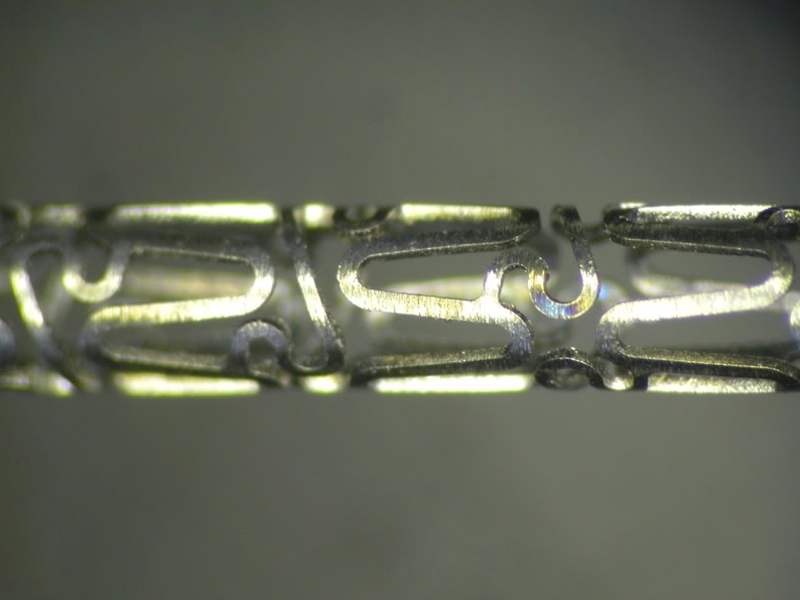

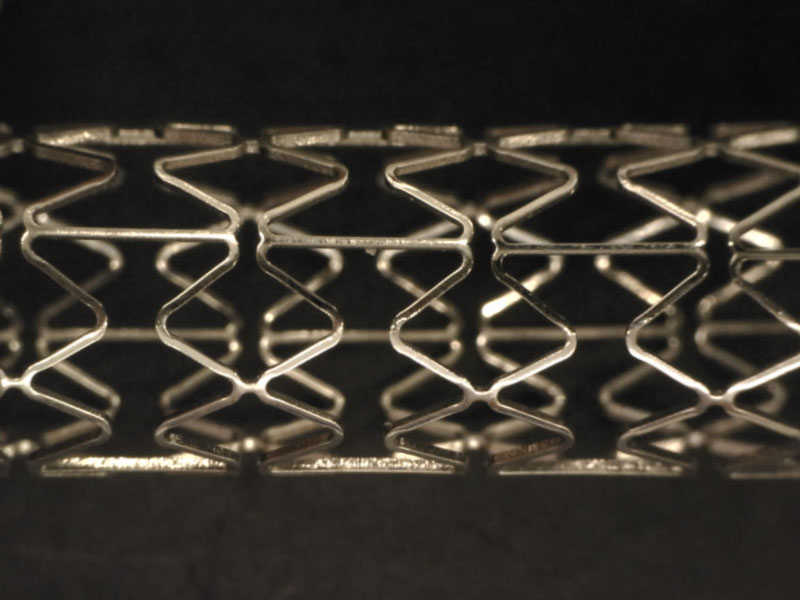

FUTA-Q’s laser processing technology allows to make fine and complicate cuttings on a small-diameter tube with variety range of materials including SUS, β-titanium, and NiTi. With our laser processing technology, we can provide elaborate products that would not be made by traditional cutting tools.

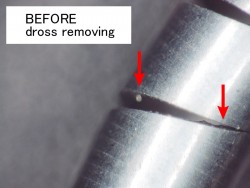

Our unique dross removing technique enables to make tube products with clean cutting surface without any burrs, which are generally caused in traditional laser cutting processing.

Specification of our laser

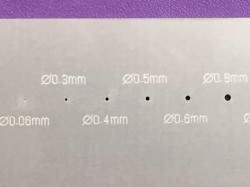

• Minimum beam diameter: 0.02 mm

• Maximum tube-wall thickness: 0.5 mm

• Maximum plate thickness: 3.0 mm

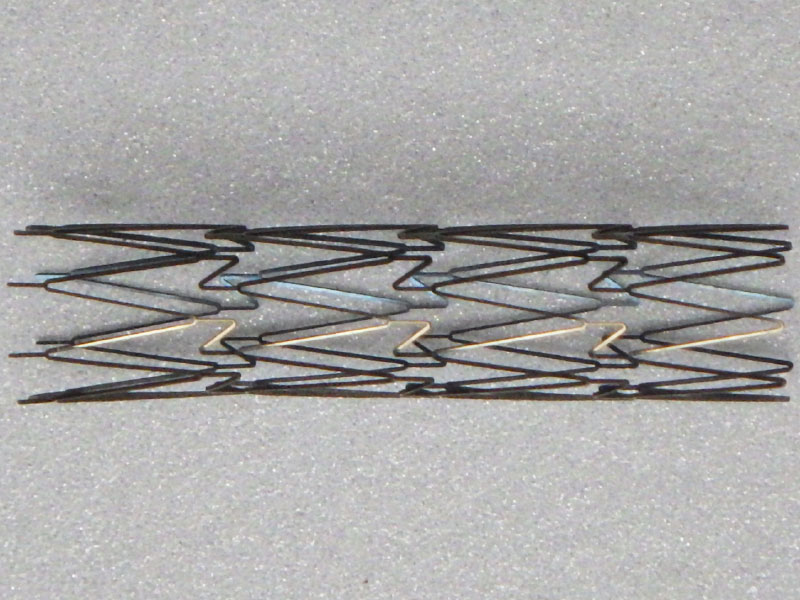

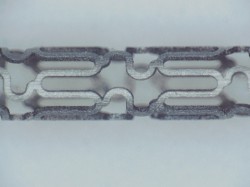

βtitanium flexible tubes

The β-titanium Flexible Tube is an epoch-making product, featuring excellent operability with its flexibility and toughness of titanium.

Even dia. 6 mm β-titanium tube, which has a property of high toughness, high flexibility, and light weight, can be bent by applying our uniquely designed slitting made by the laser cutting.

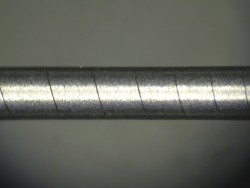

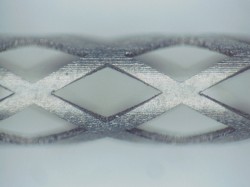

β-titanium spiral tubes

Our β-titanium spiral tubes provide unprecedented flexible operability with spiral grooves made on it by our micro-cutting laser technology used for making stents. Changing the slit width and pitches can control the flexibility and springiness at every part of the tube.