HOME » FUTA-Q Technology » Precision and Microfabrication » Precision and Microfabrication Machining Examples

Precision and Microfabrication Machining Examples

Precision and Microfabrication Machining Examples

update :

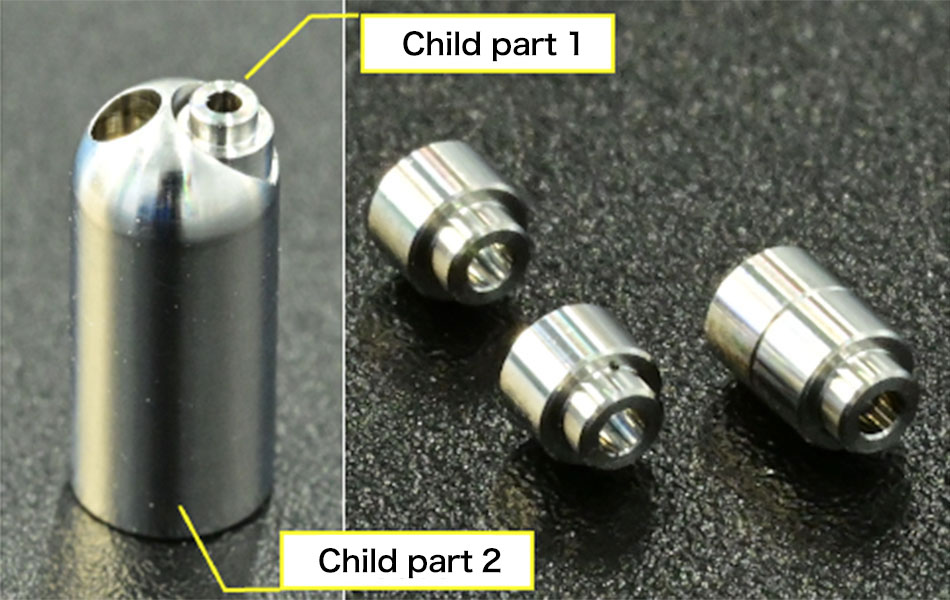

Endoscope components

The photos below show a product sample combined with small machined components made of stainless steel (SUS304). Combining various materials and processing methods, such as high hardness and flexible materials, are available according to client requirements.

- Material: SUS304

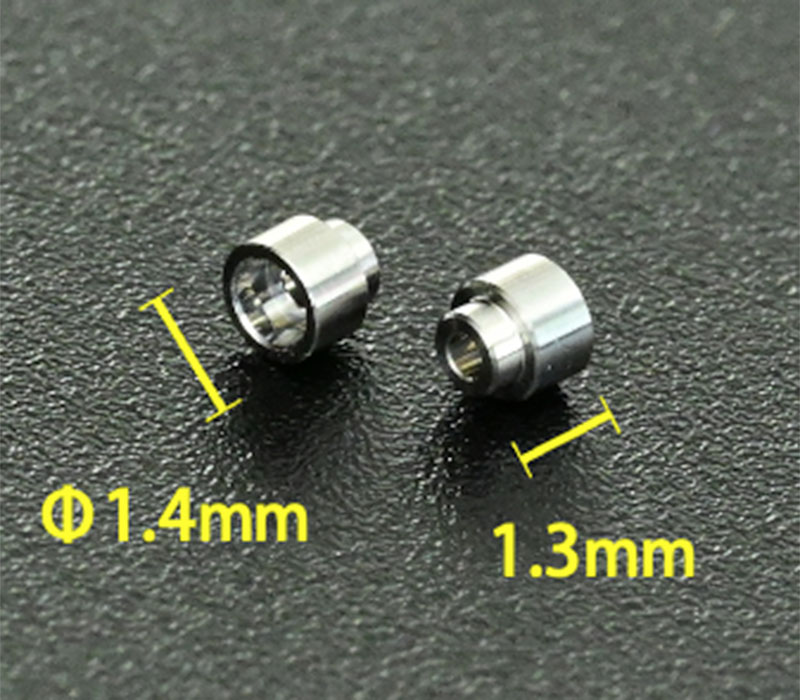

- Child part 1: Φ1.4 mm x L1.3 mm

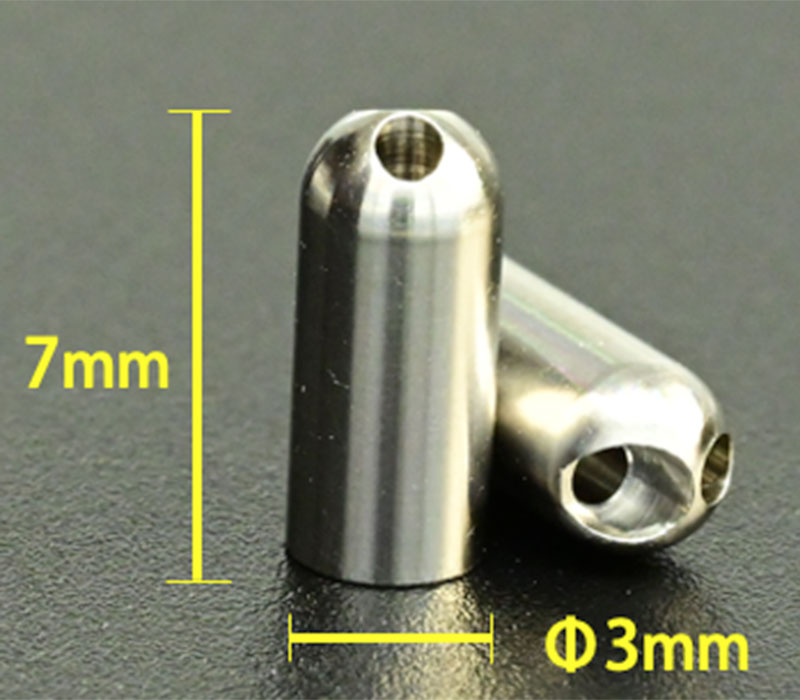

- Child part 2: Φ3.0 mm x L7.0 mm

Child part 1

Child part 2

A sample product combined with child part 1 and 2

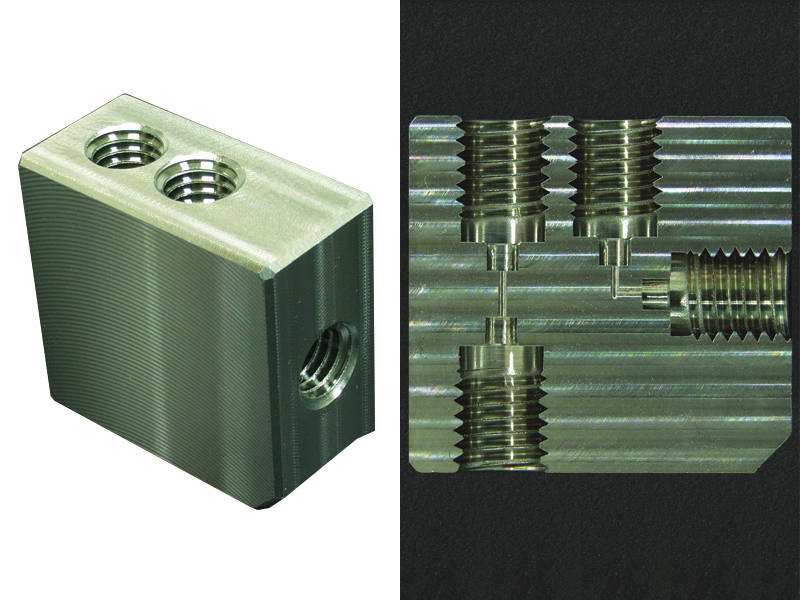

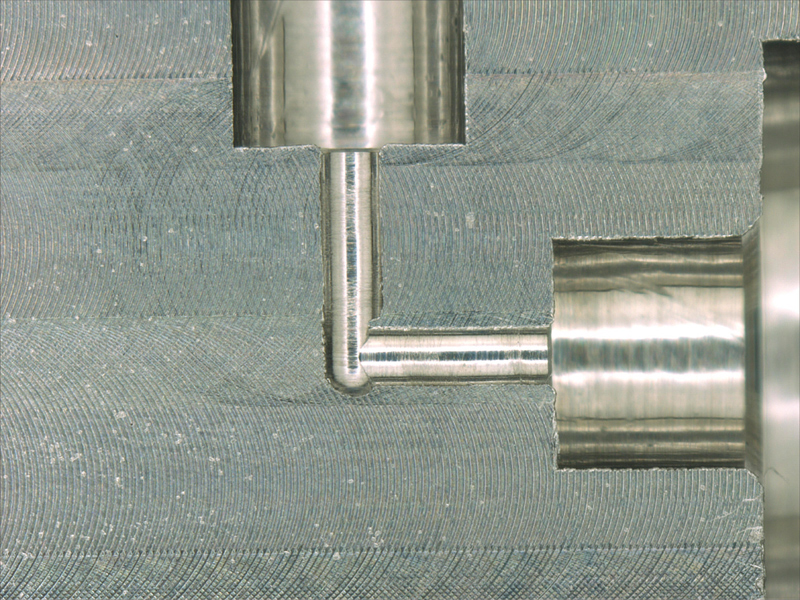

Joint block

The jointed holes above are processed only by drilling. Our precise positioning technique allows us to make the accurate alignment for these jointed holes. This kind of joint greatly improves the accuracy and speed of analytical works.

[Video clip of joint block]

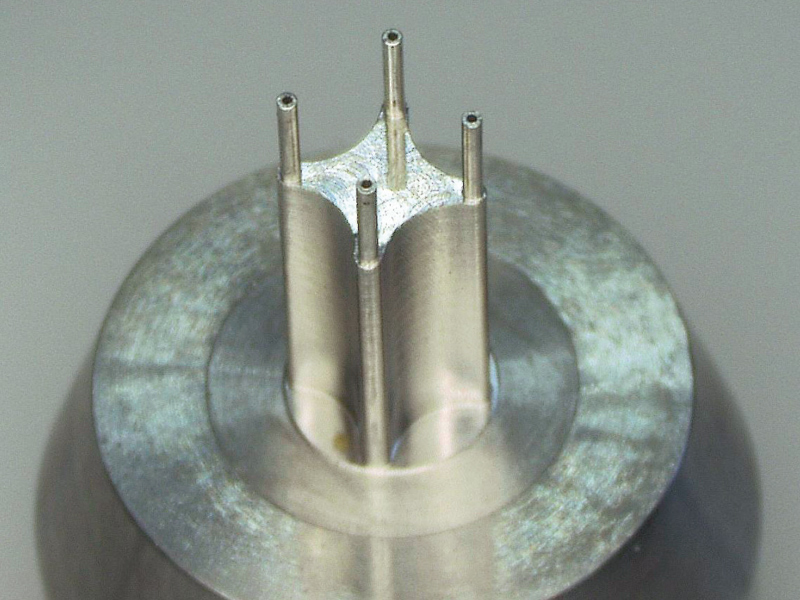

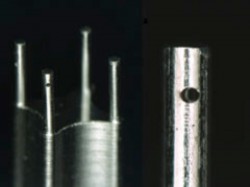

Dispensing nozzles

This dispensing nozzle is formed by our micromachining technique. The outer surface is cut down to 0.23 mm in diameter, and the hole with 0.13 mm in diameter is drilled at the center. This nozzle enables to apply adhesives onto a smaller part than ever. Furthermore, the four nozzles are shaved out from one block so that the nozzle pitch of 1/100 of PCD (Pitch Circle Diameter) is achieved.

As another type than open-type nozzles having a vertical hole, a nozzle having a horizontal hole is also available, whose tip part is welded by laser then drilled horizontally. This nozzle enables to apply adhesive from its side face. Titanium is also available as the material as requested.

[Video clip of dispensing nozzle]