HOME » FUTA-Q Technology » Precision and Microfabrication » Small diameter deep hole processing

Small diameter deep hole processing

Small diameter deep hole processing

update :

We can drill a hole with minimum diameter of 0.03 mm.

Please refer to the below for our processing experiences.

Small Diameter Hole Machining Results

| hole diameter(mm) | depth(mm) | material |

|---|---|---|

| φ0.05 | 1.0 | SUS316L |

| φ0.10 | 2.0 | TB340・SUS316 |

| φ0.15 | 2.0 | SUS316 |

| φ0.20 | 6.0 | SUS316L |

| φ0.25 | 8.0 | 64 titanium |

| φ0.5 | 36.0 | SUS304 |

| φ1.0 | 50.0 | SUS316 |

| φ3.0 | 62.0 | SUS304・Hastelloy C |

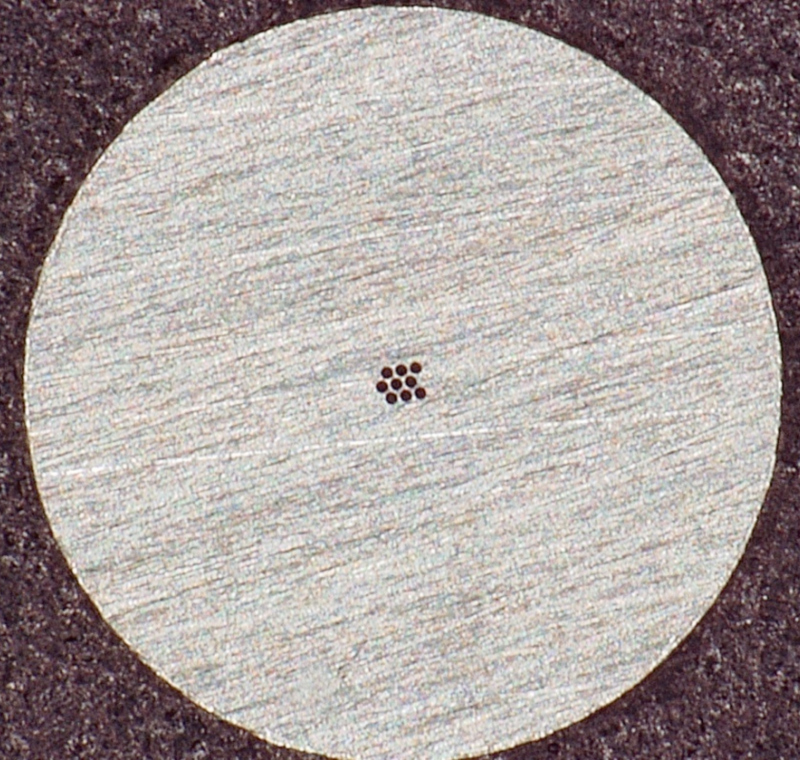

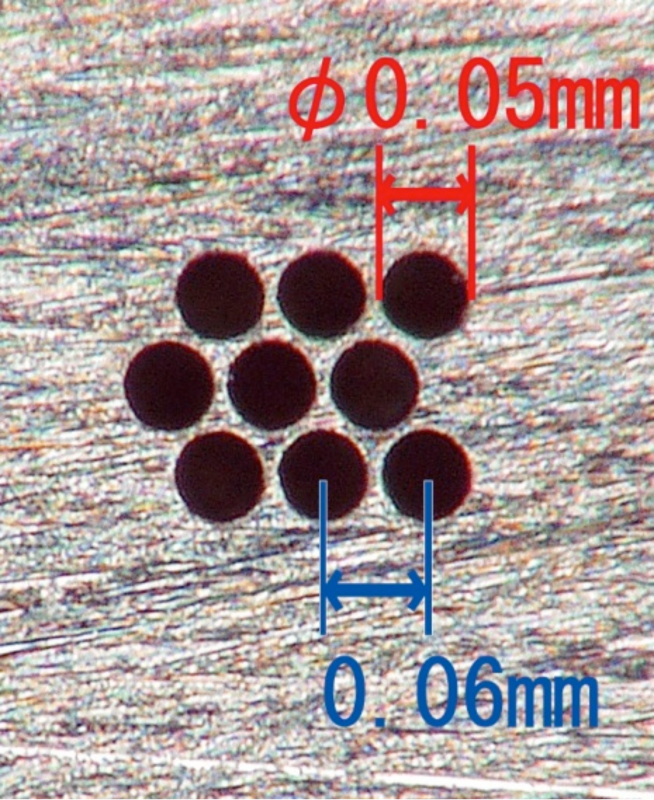

Processed samples of deep small holes

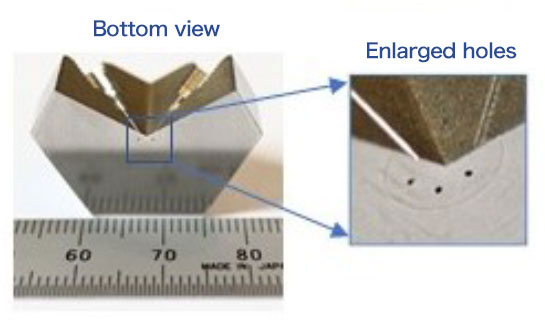

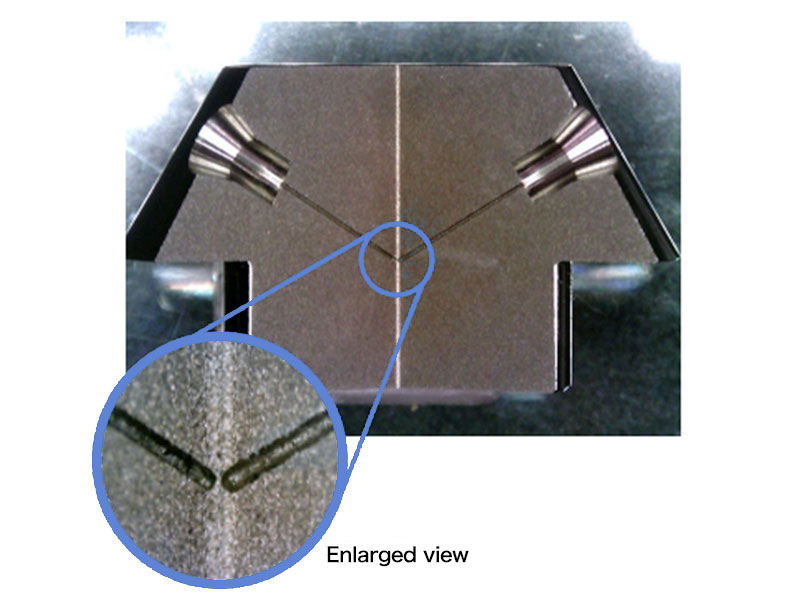

Processed sample of nozzle holes – No.1

The photos below show the cross-cut samples of the nozzles having the function for merging six flow channels into a PCD of 2.5 mm. By suppressing drill runout, these fine holes are penetrated on the open hole surface without burrs.

– Material: SUS316 / – Product thickness: 15 mm

– Diameter of six nozzles: 0.2 mm / – Nozzle inclination angle: 35°

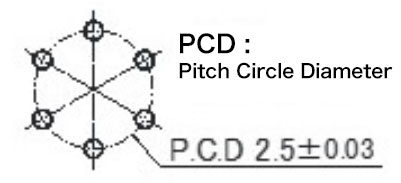

PCD stands for Pitch Circle Diameter, so the left figure shows the six holes evenly arranged on the circle with the pitch circle diameter of 2.5 mm.

PCD stands for Pitch Circle Diameter, so the left figure shows the six holes evenly arranged on the circle with the pitch circle diameter of 2.5 mm.

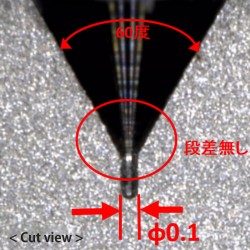

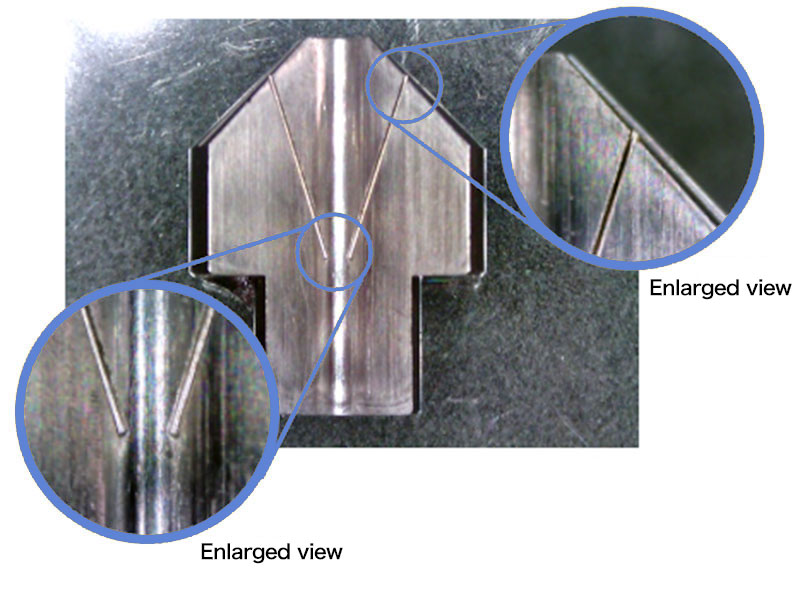

Processing sample of nozzle holes – No.2

Fine holes can be drilled at precise locations by optimizing tools and processing parameters.

- – Material: Ti-6AL-4V

- – Nozzle diameter: 0.2 mm

- – Nozzle depth: 5.0 mm

The hole ends can be positioned at a precise location.

The holes from the diagonal surface can be drilled without running sideway.

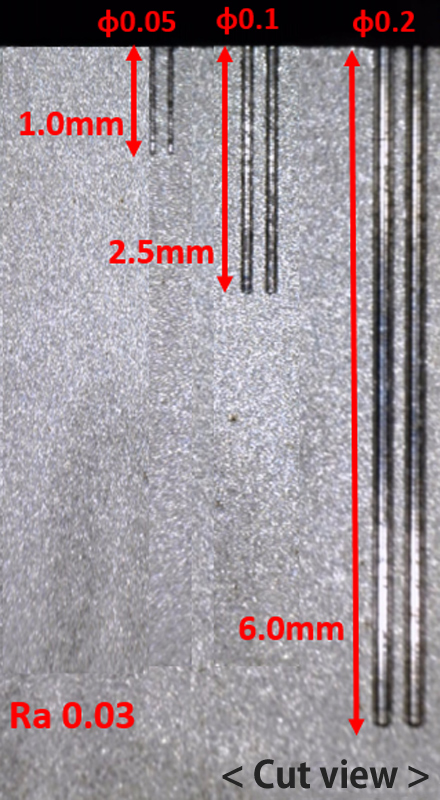

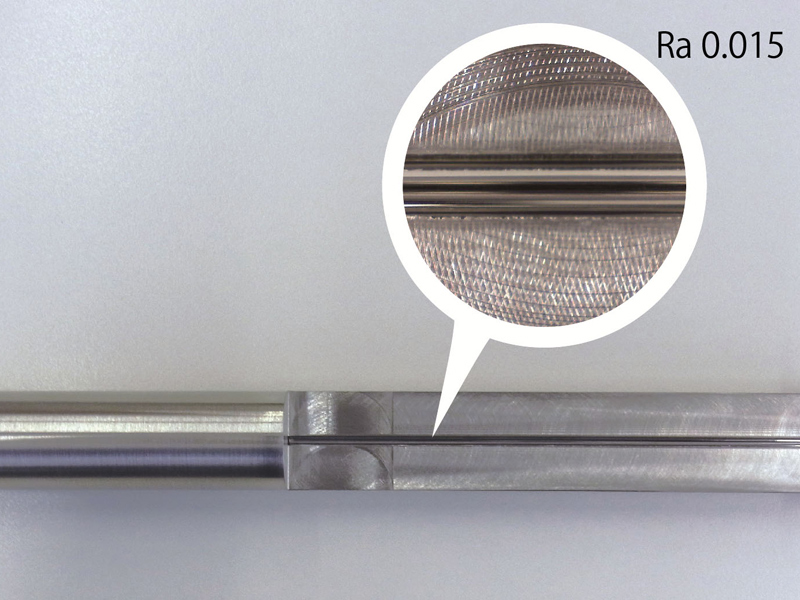

small-diameter deep hole drilling

We provide minimum deviation from straightness for small-diameter deep hole drilling, for example; deviation from linearity ≦ 0.05mm, inner surface roughness ≦ Ra 0.4 for hole dia. 0.1 mm, hole depth 2.5 mm.

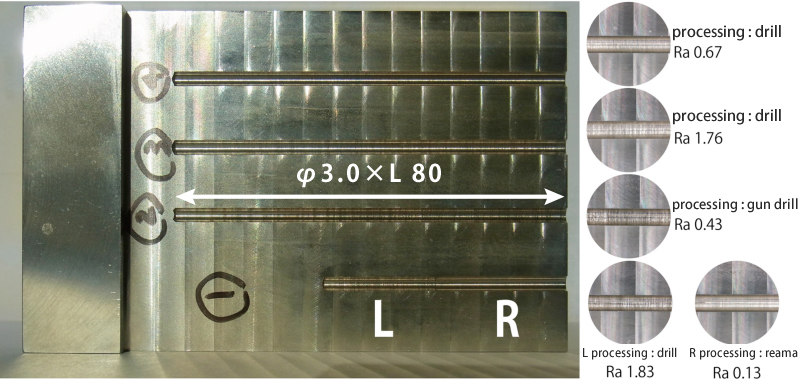

Surface roughness examples in 80mm-deep-hole drilling

(hole dia. 3.0 mm, hole depth 80 mm)

surface roughness example

drilling: Ra 0.67 – 1.83

gun-drilling: Ra 0.43

reaming: Ra 0.13