| Option |

Samples |

Features |

Laser welding

(for jointed nozzle/pipe) |

|

The sample product is consists of two SUS pipes with OD of 0.8 mm welded longitudinal together by laser. A special pipe covered with a outer pipe is available.

|

Laser welding

(for jointing parts) |

|

deformations can be obtained. The sample product on the left is welded in full-circled around the nozzle tip, automatically.

|

| Drawing |

|

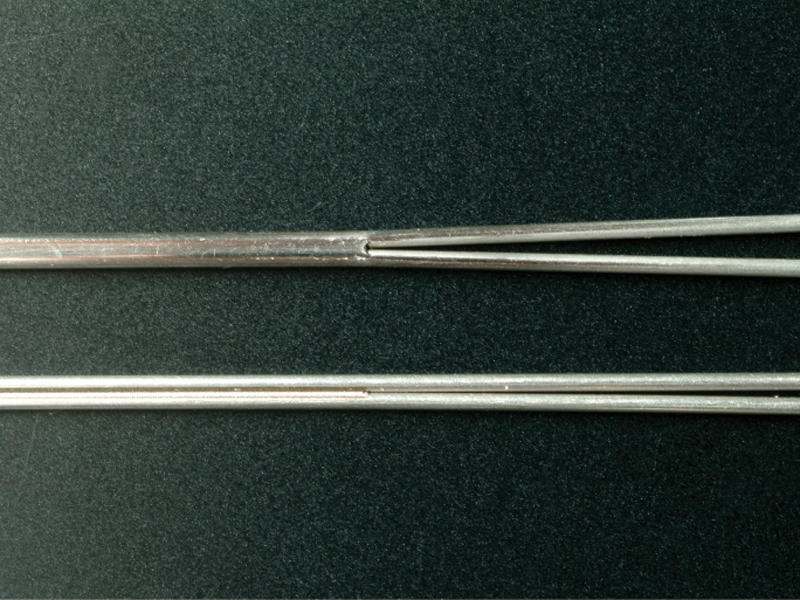

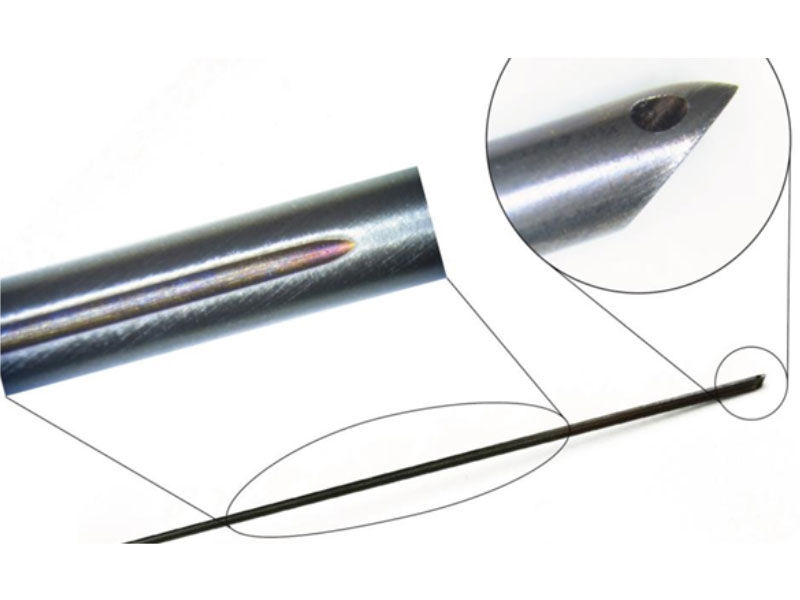

Tapered shape can be made by drawing. The minimum diameter is 0.5 mm with ID of 0.1 mm. The sample of the upper has long tapered shape, and the lower is coated with PTFE.

|

| Bending |

|

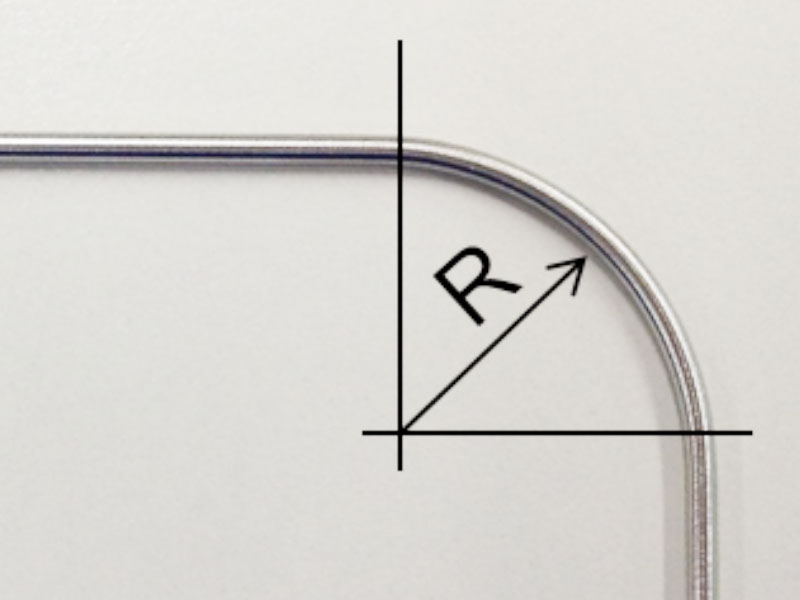

We can offer pipe bending with minimum distortion for keeping required flow channel. Possible bending radiuses depend on the diameter and wall thickness of the pipe. The minimum Rs are as follows.

OD < 1 mm: R 3 mm. OD 1 – 1.5 mm: R 5 mm.

OD 1.5 – 2 mm: R 7 mm. OD 2 -2.5 mm: R 11 mm.

|

| Inner-surface polishing |

|

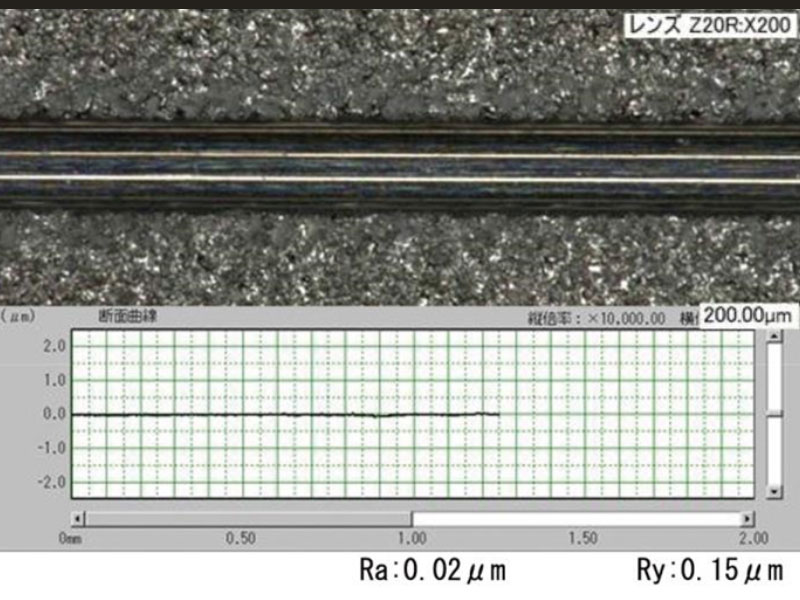

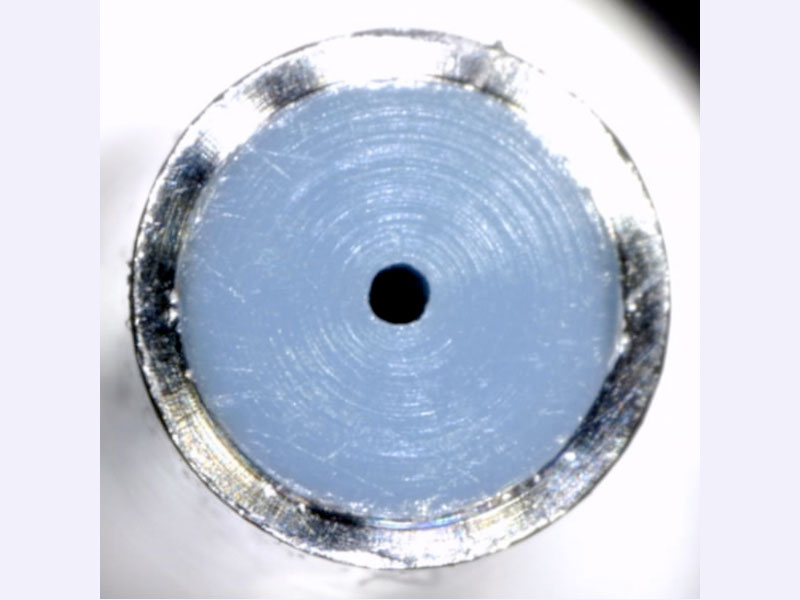

Inner-surface polishing makes smooth surface for better liquid draining.

The maximum surface roughness is Ra 0.05. The sample on the left has a surface roughness of Ra 0.02 resulting from special processing. Polishing bended or tapered part can be processed.

|

PTFE coating

(inner/outer surfaces) |

|

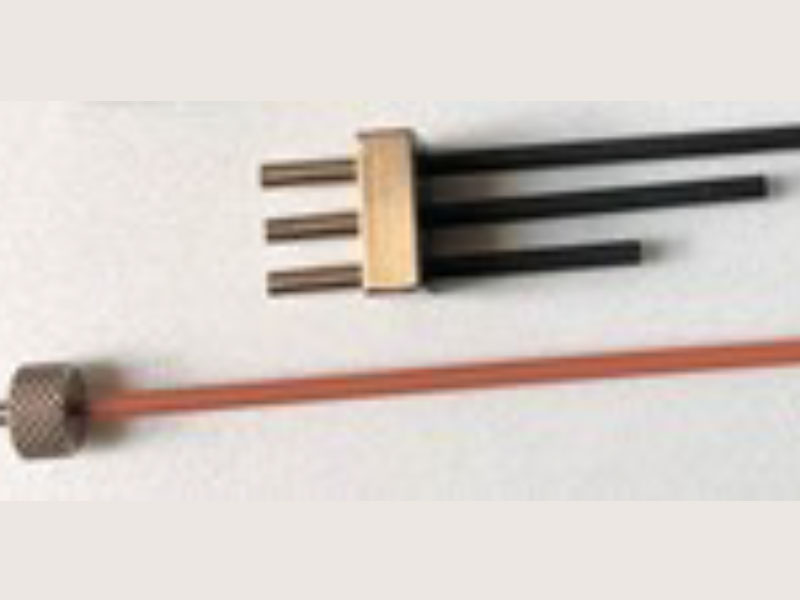

The sample on the left is a nozzle coated with PTFE. This type of coating features insulation, water-repellent, and oil-resistant properties. Black is the standard color, which has high wear resistance and chemical resistance property. Brown color one has high sliding property.

Coating thickness is 5 to 20 μm.

|

F2901 coating

(inner surface) |

|

Better liquid draining can be achieved by this F2901 inner-coating. This type of coating has high insulation, water-repellent, and oil-resistant properties. The coating thickness is less than 1 μm.

(No prohibited materials by RoHS and REACH are contained.)

|

| Horizontal hole / grooving on outer surface |

|

With horizontal or oblique holes at the needle tip, specimen can be sucked until the very little residue left.

Bleeding is possible with grooves on the outer surface.

|

Built-in functions

(heater, sensors) |

|

A heater and sensors for measuring temperatures and electrostatic capacitance can be built in a nozzle. We propose the best assembling method including laser welding, soldering, and adhesion.

|

| Hybrid component |

|

The product shown in the photo is a hybrid pipe nozzle made of PEEK and stainless steel, having excellent properties of each material together.

No adhesive is applied for the sample on the left.

|