HOME » news » TV-Media » Mami Hasegawa, working at Futaku Precision Machinery Industry Company, received the second prize in Monozukuri (manufacturing) princess contest.

Mami Hasegawa, working at Futaku Precision Machinery Industry Company, received the second prize in Monozukuri (manufacturing) princess contest.

Mami Hasegawa, working at Futaku Precision Machinery Industry Company, received the second prize in Monozukuri (manufacturing) princess contest.

update :

Mami Hasegawa, working at Futaku Precision Machinery Industry Company, received the second prize in Monozukuri (manufacturing) princess contest.

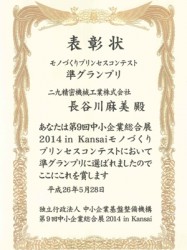

Left:prizewinner Mami Hasegawa

Right:Monozukuri (manufacturing) princess contest Second Prize citation

What’s Monozukuri princess contest?

It is the contest hosted by The Japan International SME Exhibition 2014 in Kansai district, to choose a woman who puts a lot of effort in manufacturing and tries so hard to make her dream come true.

It is the contest hosted by The Japan International SME Exhibition 2014 in Kansai district, to choose a woman who puts a lot of effort in manufacturing and tries so hard to make her dream come true.

Futaku Precision Machinery Industry Company covered Mami’s charms and her daily work closely and decided to recommend her. Then, she brilliantly won the second prize.

About Mami Hasegawa who received the second prize

Affiliation & post:production department production section in Yagi factory(in charge of finishing processing)

Affiliation & post:production department production section in Yagi factory(in charge of finishing processing)

After graduating Kyoto prefectural Nougei high school in 2012, her career teacher recommended her to the company, and joined in it as a new graduate.

Now, she takes an active part in finishing micro-machining process.

《her business outline》

She is in charge of the final micro-machining process of medical, analytical, and semi-conductive products. She mainly specializes in finishing processing of stainless steel and titanium alloy, such as mirror polishing and deflashing, and her skill has contributed for accuracy improvement.

・Deburring : The components of deburring are dimension, shape, surface roughness and so forth. These aspects must meet customers’ demands. In order to do that, an outstanding analog technique, that is earned by excellent effort and repetitive training, is essential. After approximately two years, she grew up rapidly and now she can process highly skilled deflashing. She is mainly in charge of core parts for hemanalysis devices. Her ductile manipulation is simply wonderful and even veteran people praise her saying she has aptitude for this field. It’s very certain that she is still going to polish her technique more and be the one who the company cannot lose.

・Mirror polishing : It’s the process to burnish products and increase their surface accuracy by using machines. The balance among finger power applied to both products and machines, and the movement of brade is essential. Without that, products cannot be polished with high-precision. In order to do this work perfectly, she must be highly experienced and must use his/her five senses very meticulously. She has been in charge of this position for three months. While she is still young, she is very excellent at precise work as she always repeats accuracy testing. She is definitely an outstanding person who adds value to this company’s products.

《Recommendation Reason》

She is only 20 years old now, but she is so confident and responsible for her job. She says “I love manufacturing, and so proud that I could work in manufacturing industry field just like my father.” Her coworkers are always impressed by her remarkable growth.

While most workers in this field are male, she always tries her best. When she was a novice, she interpreted wrongly, and produced a number of inferior products. She cried all night long. However, she overcame such a painful memory, and grew up rapidly as she said she checked next day’s working schedule before going to bed.

Then, she is so amiable that her coworkers always get relaxed. Not only working so hard, but also she can make the mood of the workplace better. She is definitely the princess whom everyone is so proud of.

《Manufacturing career》

She was innately dexterous, and was good at industrial arts and homemaking at school. Her teacher noticed her outstanding skill, and recommended her to apply for this company. Since her father works in the industrial world, she has felt a strong sense of affinity.

However, people engaged in metalworking field are very scary for her at first. Especially, she couldn’t understand how craftsmanship was engaged in strong persist and concentration. When she was a novice, she couldn’t talk to her supervisors because they were so concentrated that her question might have bothered them.

Now, she has improved her finishing processing skill, and she is still getting better little by little. Then, she now knows exact timing to ask coworkers questions. In her second year, her challenging spirit grew up more and she is confident in her skill. She says “I’m in charge of finishing processing, which means that if I fail carelessly, other coworkers’ effort won’t be rewarded. And, I feel sympathy toward products that I make.” This message is such a brilliant remark as a manufacturer. Our company definitely can’t lose her.

Recommender:Naoaki Futaku, managing director at Futaku Precision Machinery Industry Company.