HOME » Machinery Introduction » Centerless griding for fine wires and small tubes

Centerless griding for fine wires and small tubes

Centerless griding for fine wires and small tubes

update :

What is centerless grinding?

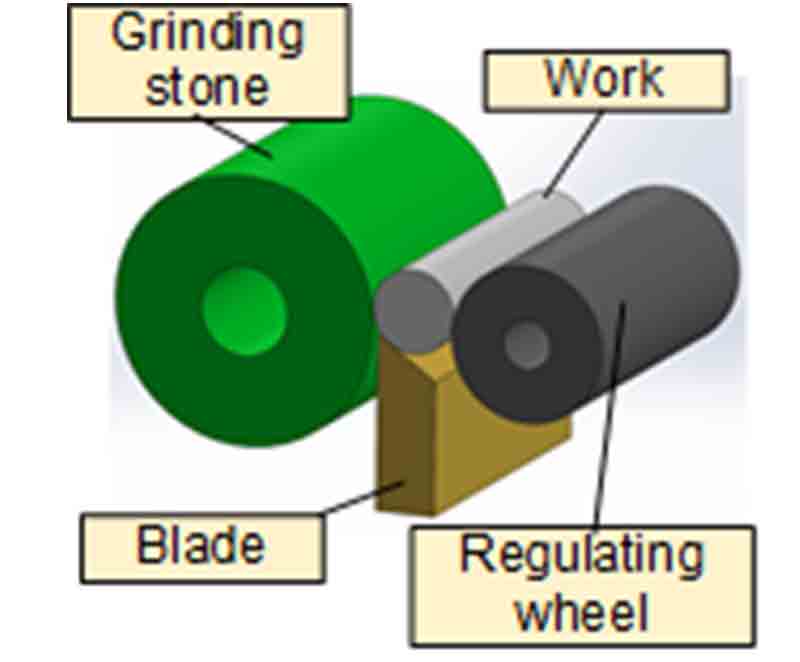

Centerless grinding process requires no supports for the work’s center while processing.

The work is rotated while supported by a regulating wheel and ground with a griding stone.

This machining method is suitable for grinding the outer diameter of a long cylindrical work in a uniform manner.

Various kinds of materials including titanium or ceramics can be processed by choosing a suitable grinding stone to the work.

Centerless grinding for small pipes

The outer diameter of a small diameter pipe can be ground in high precision by adjusting the spindle axis of the grinding stone to be parallelly located with that of the regulating wheel. In the example on the right figure, the outer diameter of the work will be ground till the work butts against the surfaces of the grinding stone, the regulating wheel, and the blade, resulting in a product with an accurate diameter and stable roughness.

Centerless grinding for thin wires

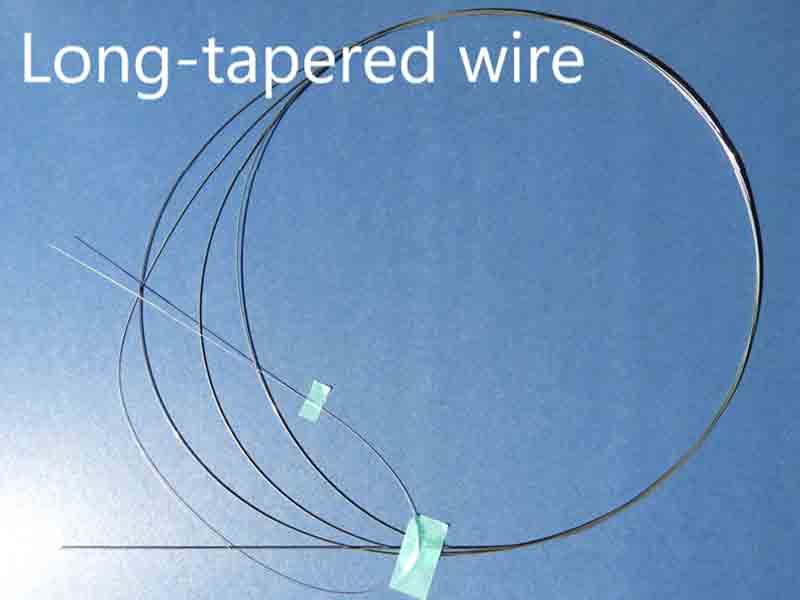

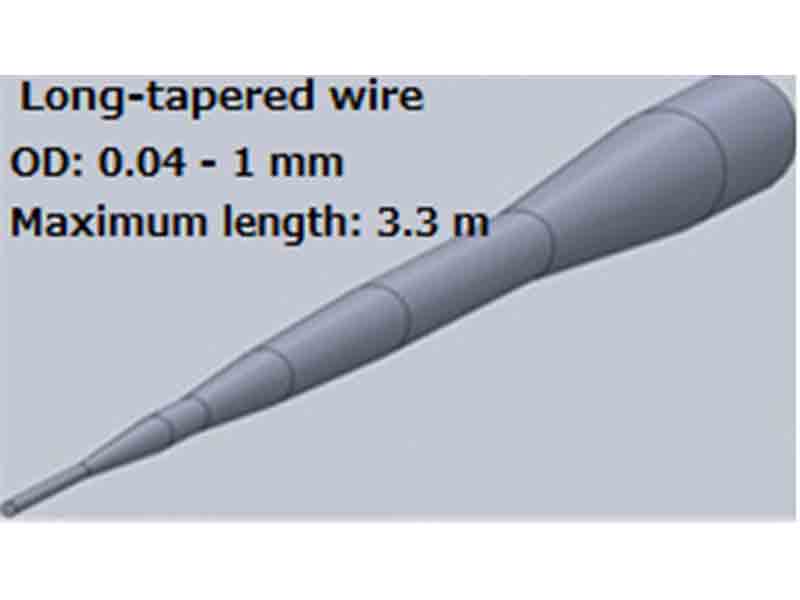

The machining tool for making long-tapered wires used for medical equipment such as catheters or guide wires.

【 Centerless grinder 】

In grinding of an ultra-fine wire, the wire can be ground into a tapered shape by controlling the gap between the grinding stone and the regulating wheel using a computer program. The photo below shows an example of the tapered wire with multi-diameters which gradually become narrow from 0.4 to 0.04 mm. The grinding machine on the photo can continuously process wires with 3.3 mm long with automatic loading and unloading.

| Wire materials | Stainless steels (SUS304V etc.) NiTi, β-titanium, Cobalt alloys (under development) |

| Outer diameter of a work | 0.24 – 1 mm |

| Finished diameter: | 0.04 mm to a material diameter ± 4 μm |

| Maximum grinding length | 750 mm |

| Available grinding pattern | Multistage long tapers by computer controlling |

| Maximum product length | Grinding length + 1.0 mm to 3.3 m (including ground length) |

Long-tapered wire used in medical and other industries

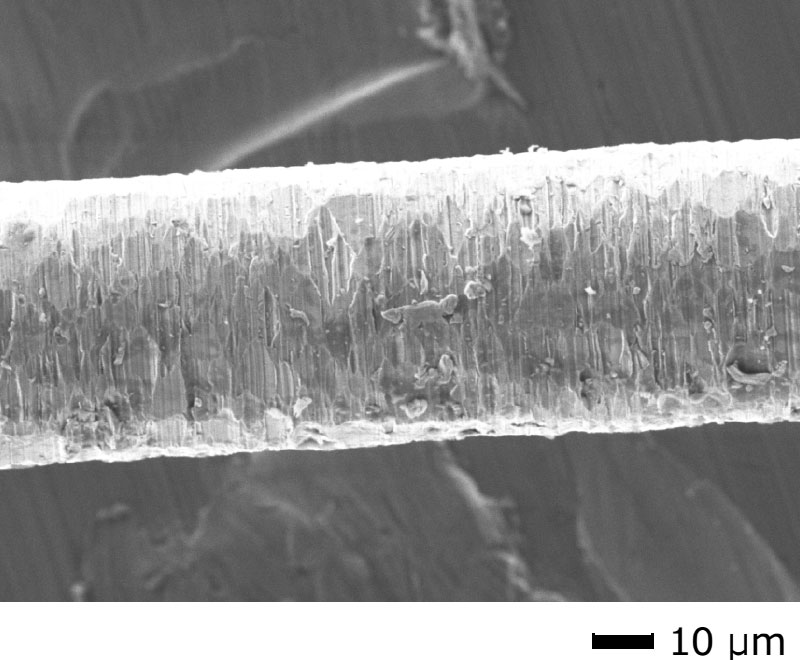

We are utilizing a scanning electron microscope (SEM) with an energy dispersive spectroscopy (EDS) to develop and upgrade our process technologies, optimize the process conditions, and confirm our product quality.

The surface examples of a finished work captured with the SEM-EDS. (SUS304V wire with 0.04 mm in OD having a long-taper)

Which is correct, centerless grinding or centerless polishing?

What is the difference between polishing process and grinding process? There seems to be no significant difference between their meanings, isn’t it?

“Polishing process” is used for a process like burnishing using abrasive grains, while “grinding process” is used for a process like scraping off the work’s surface using a rotating grinding stone. Some people, however, call the process using a grinding stone “polishing”.

So, the other question come to mind: how should we call the process that gives us the both effects of “polishing” and “grinding” at the same time?

Why not be consistent?

Both machining methods are surely indispensable processes for manufacturing high quality products for us to meet our clients’ needs.