Beyond precision machining…

Toward a first-class supplier in future medical care

Case study1

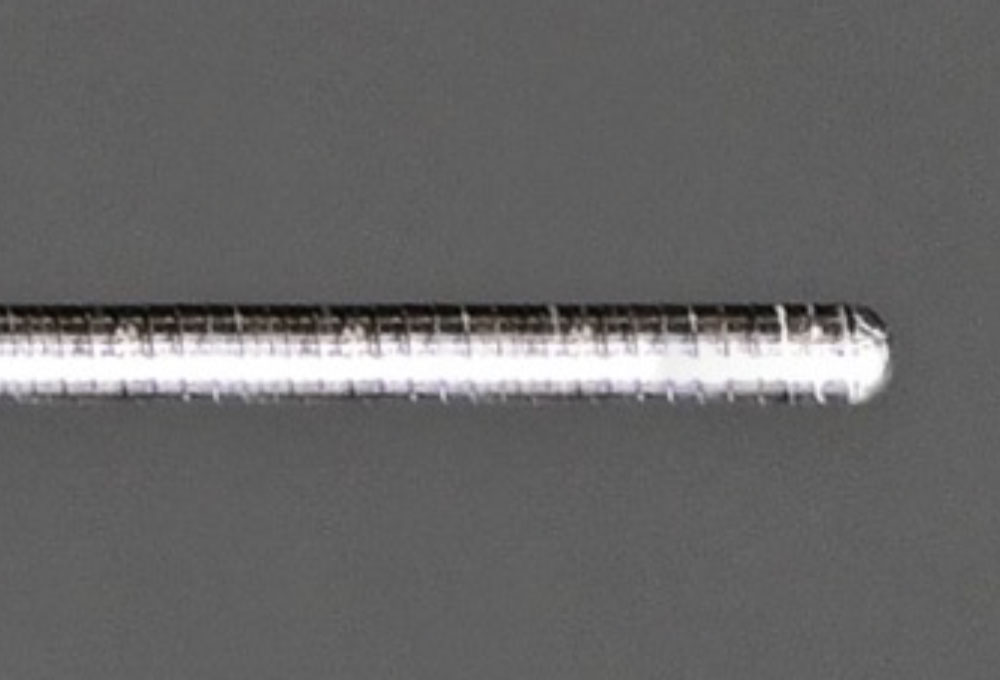

For achieving advanced operability

Long-tapered wire

A multistage long-tapered wire can be produced with the minimal diameter of 0.04 mm, the grinding length of 750 mm, and the maximum length of 3.3 m. This kind of wires are being used for medical devices such as a guide wire.

Case study2

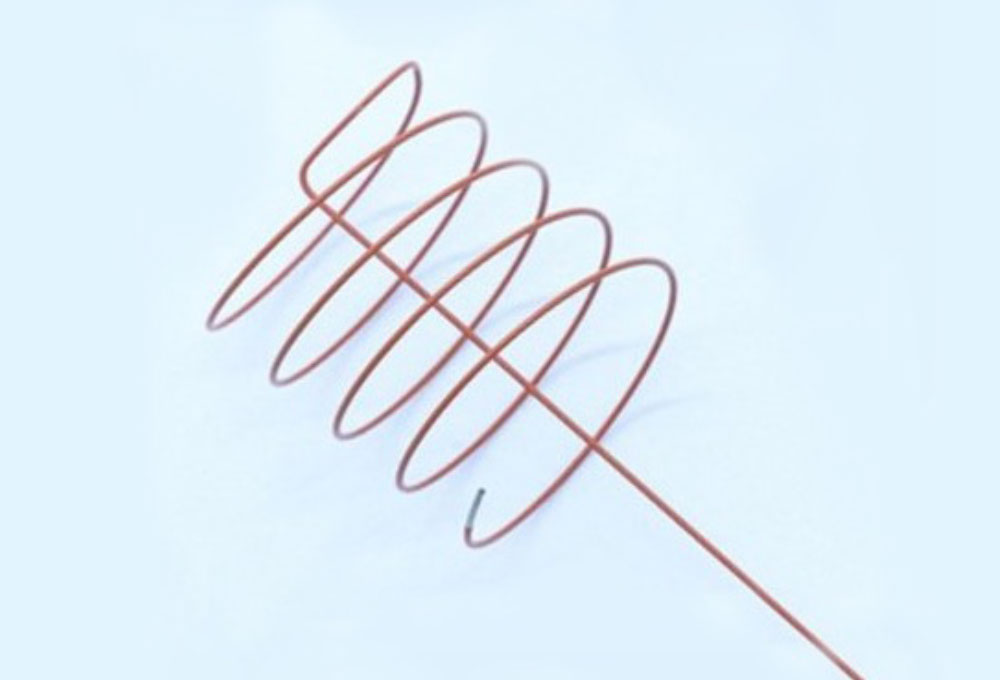

For superelasticity and shape memory function

Nickel-titanium products

The photo on the right shows a sample product of super elastic wire with shape memory treatment. A nickel-titanium medical device can be formed into a suitable shape for a treatment.

Furthermore, fluorine coating (PTFE) can be applied for providing antifouling function.

Case study3

For tiny medical devices with higher functionality

Microfabricated components

The photo on the right shows a tiny microfabricated component made of ceramic that fit on a fingertip, having the outer diameter of 1.6 mm and a tapered hole with the minimum diameter of 0.32 mm.

Case study4

For functional components for an endovascular treatment device, etc.

Slit processing with laser

Ultra-short pulse laser in picosecond or nanosecond order can cut out fine shapes from a wire or small diameter pipe without degrading the property of its material functionality.

Case study5

For application-specific puncture characteristics

Needle tip forming

A tip of needle or nozzle used in medical devices can be processed into variety of shapes so that it can have suitable characteristics, such as puncture resistance, for its application. The Menghini shape, for example, is featured by lower puncture resistance.

Case study6

For higher functionality

Assembled products

Assembling multiple components is often required to achieve the functions and characteristics needed for medical treatment. FUTA-Q can meet the requirements by utilizing a variety of joining techniques such as soldering, adhesion, and caulking.

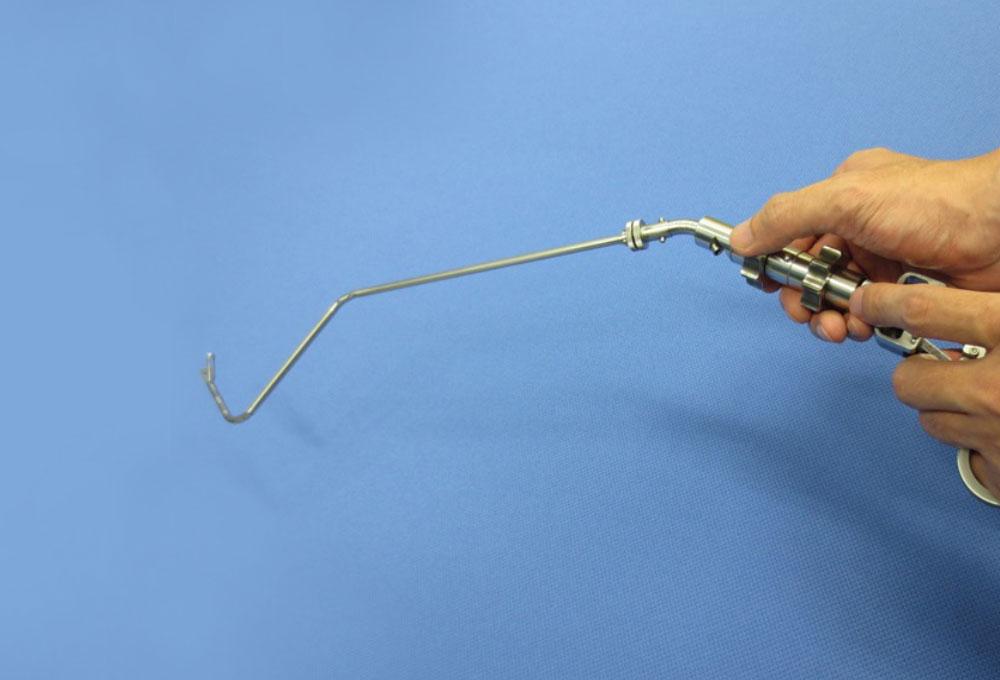

Case study7

For one more step in medical treatment

Full-custom designed specialty forceps

The photo on the right shows a single-hole laparoscopic forceps that is structurally designed and embodied through repeated prototype tests, based on the surgeon's requirements who actually used it. This has an angle-adjustable three bending sections and the gripping section at the end rotates.