HOME » FUTA-Q Technology » Bore polishing Surface treatment » I.D Polishing (Bore polishing/InternalPolishing)

I.D Polishing (Bore polishing/InternalPolishing)

I.D Polishing (Bore polishing/InternalPolishing)

update :

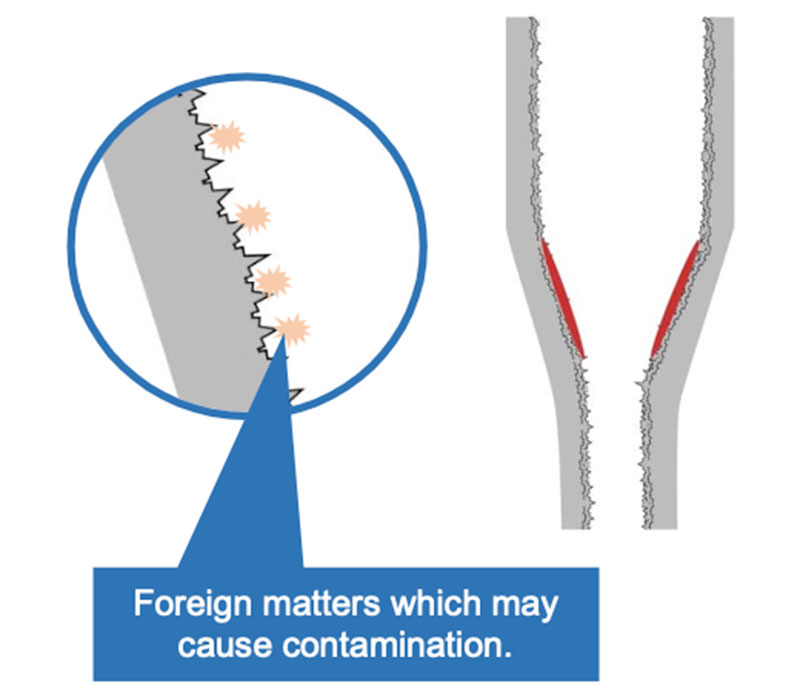

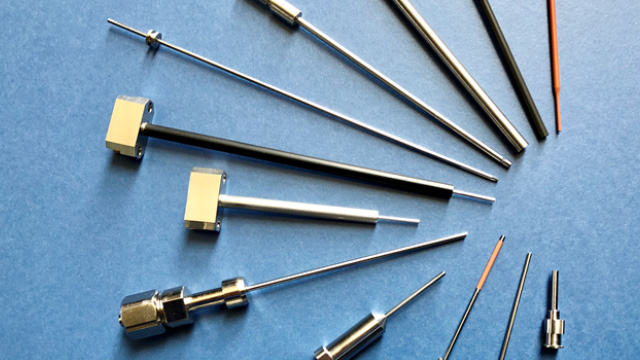

The inner surface of a nozzle or needle is sometimes required to have precise roughness or dimensions in order to control the amount of fluid flowing through it or to prevent impurity foreign elements from adhering to it. FUTA-Q can provide high-precision hollow-pipes for meeting this kind of requirements by combining various inner-surface polishing techniques as well as utilizing our unique pipe making and machining techniques.

Inner polishing for small-diameter pipes

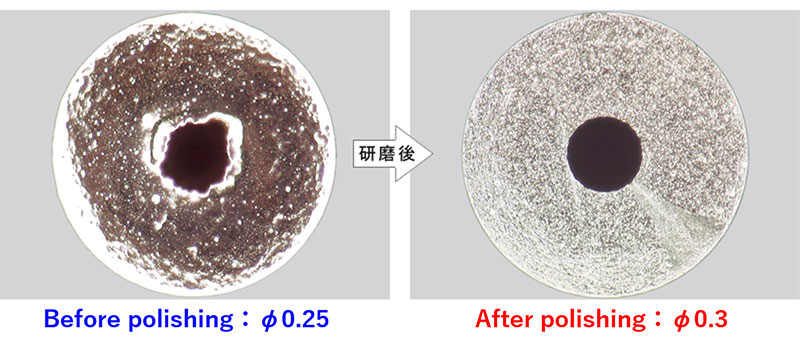

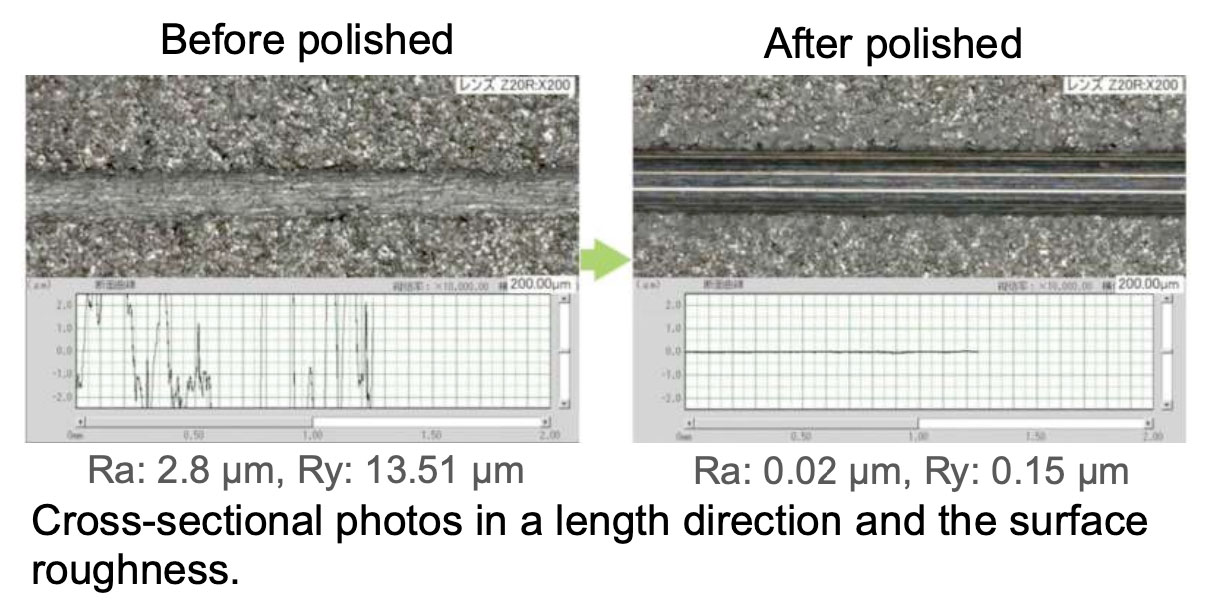

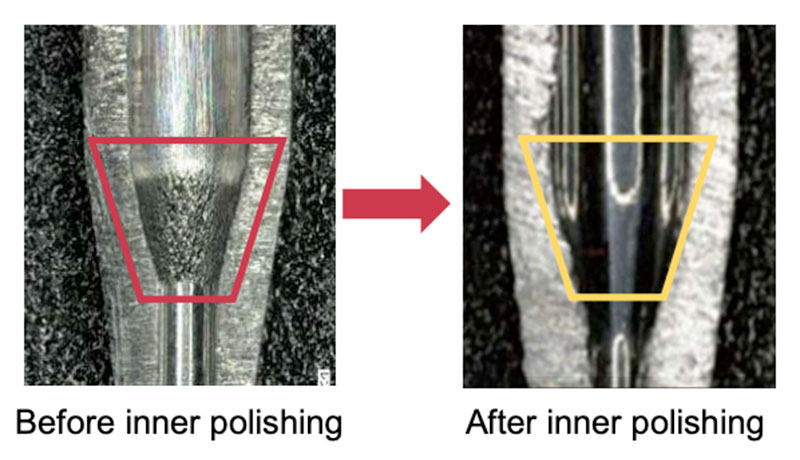

The Inner diameter (ID) and surface roughness can be adjusted to the desired value through inner surface polishing. The photos below show the polished results of a SUS316L pipe with 0.1 mm OD and 0.3 mm ID.

Cross section of commercially available small diameter pipe after I.D Polishing.

Enhancing roundness by Inner-Diameter Polishing

• SUS316Lφ1.6×φ0.25

Method of polishing the inner surface of a small-diameter pipe

The list below shows the four pipe interior and part polishing methods available by FUTA・Q.

| Polishing method | Characteristics | Application | |

|---|---|---|---|

| Physical polishing | Fine tube polishing | Polishing method that directly polishes the inner surfaces of nozzle products and straight pipes with abrasive grains | Mass-produced products |

| Special polishing | Method of polishing the inner surface of curved pipes or tapered pipes | Mass-produced products | |

| Buffing | Method of polishing the internal surface of a short pipe with a product surface and an internal radius Φ4 or more. | Mass-produced products | |

| Chemical polishing | Suitable for parts of complex shapes. | Mass-produced products | |

Method of melting metal surface, electrolytic polishing has problems with uniform finishing because the electrode positions in the pipe are shifted.

Magnetic polishing requires a large-scale device and a number of processes to remove residual abrasive grains in a small-diameter pipe.

List of pipe materials small-diameter and abrasive specifications

The list below shows the specifications of I.D Polishing for small diameter pipes that can be mass-produced and available pipe lengths.

As there are many types of metal materials handled, some of them cannot be listed. So the table below shows standard sizes.

In addition to SUS, we can also handle difficult to cut materials such as titanium and cobalt alloys.

About metal materials and ultra-small pipes not shown in the table, please feel free to contact us.

| Materials of small-sized pipes (SUS304, SUS316L, β-titanium, pure titanium, MP35N※, ELGILOY*, etc.) | |||||||

| Gauge (G) | Outside diameter(mm) | Internal Diameter(mm) | Length (mm) | Inner surface roughness (μm) | SUS | Ti | Co alloy |

|---|---|---|---|---|---|---|---|

| 26G | 0.45 | 0.23 | 230 | ≦Ra0.8 | 〇 | 〇 | ➖ |

| 25G | 0.51 | 0.26 | 230 | ≦Ra0.8 | 〇 | 〇 | ➖ |

| 24G | 0.55 | 0.30 | 230 | ≦Ra0.2 | 〇 | 〇 | ➖ |

| 23G | 0.63 | 0.33 | 230 | ≦Ra0.2 | 〇 | 〇 | ➖ |

| 22G | 0.71 | 0.41 | 230 | ≦Ra0.06 | 〇 | 〇 | ➖ |

| 21G | 0.81 | 0.51 | 480 | ≦Ra0.06 | 〇 | 〇 | 〇 |

| 20G | 0.88 | 0.58 | 480 | ≦Ra0.06 | 〇 | 〇 | 〇 |

| 19G | 1.06 | 0.70 | 480 | ≦Ra0.06 | 〇 | 〇 | 〇 |

| 18G | 1.26 | 0.90 | 480 | ≦Ra0.06 | 〇 | 〇 | 〇 |

| 17G | 1.48 | 1.12 | 480 | ≦Ra0.06 | 〇 | 〇 | 〇 |

| 16G | 1.61 | 1.25 | 480 | ≦Ra0.06 | 〇 | 〇 | 〇 |

| 15G | 1.81 | 1.45 | 480 | ≦Ra0.06 | 〇 | 〇 | 〇 |

| 14G | 2.11 | 1.69 | 480 | ≦Ra0.06 | 〇 | 〇 | 〇 |

| 13G | 2.41 | 1.99 | 480 | ≦Ra0.06 | 〇 | 〇 | 〇 |

| 12G | 2.76 | 2.40 | 480 | ≦Ra0.06 | 〇 | 〇 | 〇 |

| 11G | 3.06 | 2.64 | 480 | ≦Ra0.06 | 〇 | 〇 | 〇 |

| 10G | 3.4 | 2.84 | 480 | ≦Ra0.06 | 〇 | 〇 | 〇 |

| Wall thickness | 1.6 | 0.60 | 480 | ≦Ra0.06 | 〇 | 〇 | 〇 |

※ Cobalt-alloy MP35N® is a trademark of SPS Technologies.

※ Cobalt-alloy ELGILOY® is a trademark of Elgiloy Specialty Metals.

I.D. Polishing Achievements for Small-Diameter Pipes

We can also handle I.D. polishing for metal materials and ultra-fine pipes not listed here, according to your specifications.

Small-Diameter Pipe Sizes

I.D. polishing is possible for pipes with a minimum inner diameter of φ0.1mm.

- ・Pipe length: Straight pipes up to 700mm

Bent pipes up to 300mm - ・Pipe inner diameter: Minimum φ0.1mm

Surface Roughness

- ・Standard: Around Ra0.05

- ・Special specification: Ra0.01 (Please consult us depending on the application)

Shapes

In addition to straight pipes, we are capable of polishing complex internal shapes that are generally considered difficult to machine.

- ・Straight shapes

- ・Bent shapes

- ・Tapered shapes

Materials

We can process a wide variety of difficult-to-cut materials.

- ・SUS

- ・Titanium

- ・Titanium alloys

- ・Cobalt alloys

- ・Copper

- ・Other difficult-to-cut materials

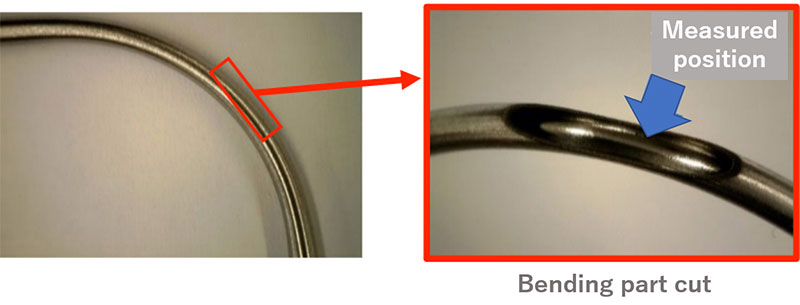

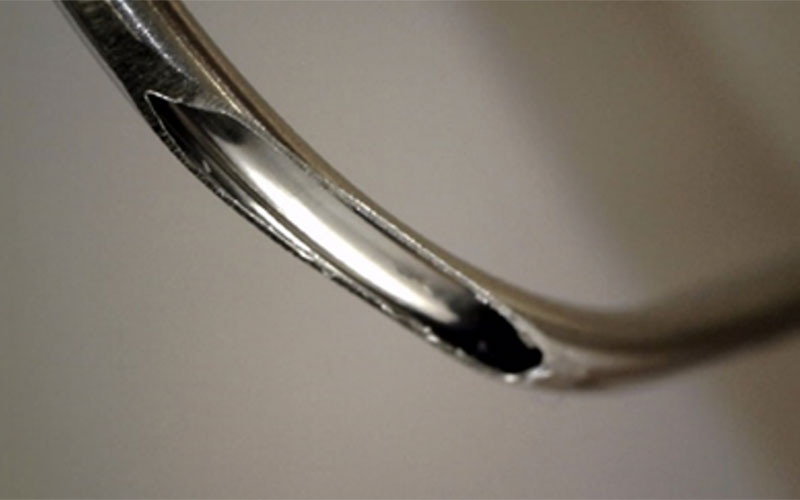

Inner surface polishing for bent pipes

“Wrinkles” inside the bending area caused by a bending process can be also polished.

SUS 316L with Φ1.35 OD x Φ1.11 ID mm Total length: 100 mm (bent at the center)

Bent pipe.

Dimension guideline for pipe bending with inner surface polishing

– Length to be bent area: 300 mm longest

– Outer diameter: 5 mm at maximum

– Inner diameter: Φ0.1 mm at minimum

– Pipe-wall thickness: 0.1 mm at minimum

– Bending radius: 2 mm at minimum

New!

I.D Polishing for bent pipe

It is possible to remove wrinkles inside the internal radius generated during the bending process.

・ Size: ODφ1.35 IDφ1.11

・ Material: SUS316L

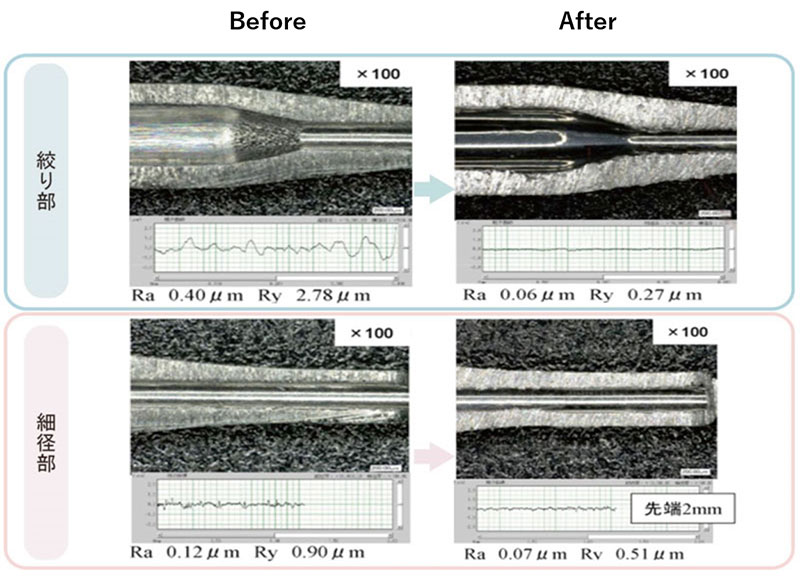

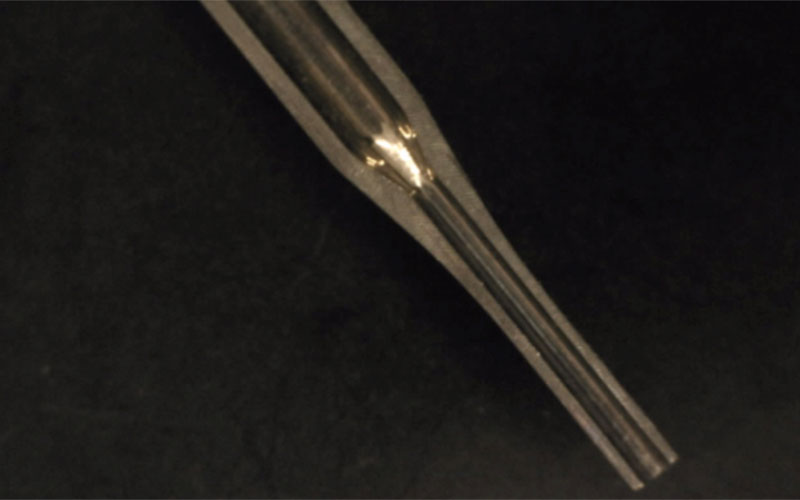

Inner polishing for tapered pipes

The inner surface of a tapered pipe consisting of three parts with different diameters; thicker, tapered, and thinner sections; can be polished by using various inner surface techniques.

Cross-sectional photo in a length direction of Tapered pipe.

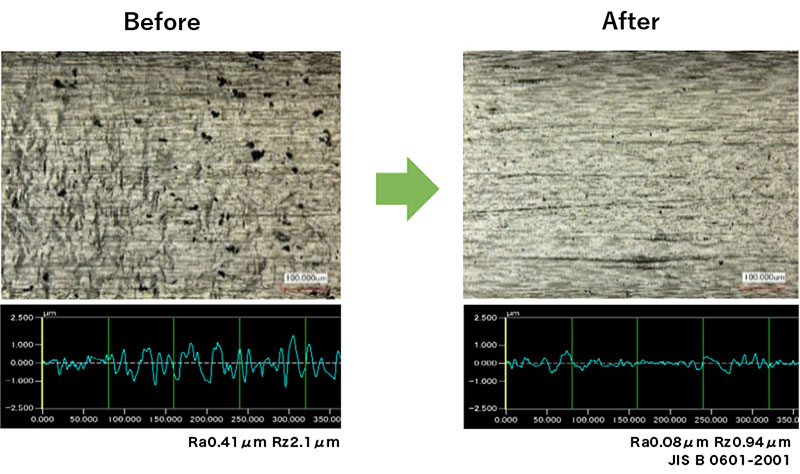

Inner surface polishing for tapered (drawn) areas

Wrinkles formed on the inner-surface at a tapered area can be removed with our self- developed inner surface polishing technique to make the inner surface mirror finished of Ra0.2 or less (in some cases, Ra0.05 was achieved).

Taper Machining: Processing Examples

※ Applicable size: Pipes with an outer diameter of φ6 or less

In the tapered (swaged) sections of the pipe, the wall thickness increases during the reduction process, causing wrinkles and reducing the inner surface finish. However, FUTA·Q’s proprietary technology enables an improved surface finish.

By applying internal polishing, contamination is minimized to the utmost degree, allowing accurate and stable data collection and enabling high-precision analysis in medical and analytical equipment.

• Titanium Nozzle (DAT51)

Large radius ODφ1.82 IDφ1.08 Small radius ODφ0.96 ID0 51 Total length L=180

Frequently Asked Questions about I.D. Polishing, Precision Machining, and Contract Processing

- What are the benefits of inner diameter polishing?

- Polishing the inner diameter smooths the flow of fluids and reduces the adhesion of fluid components to the pipe surface. This helps stabilize performance and improve maintainability.

- What products typically use I.D. polishing?

- It is widely used in pipes and nozzles where fluid passage greatly affects function, such as medical devices, analytical instruments, and filling or dispensing equipment.

- What pipe sizes can FUTA-Q process?

- Depending on the material and shape, we can polish pipes with an inner diameter of φ0.1mm or larger. For straight pipes, lengths up to 700mm can be processed.

- Can I.D. polishing be applied to shapes other than straight pipes?

- Yes. By selecting appropriate polishing methods and processing sequences, we can also polish tapered or bent pipes, not just straight ones.

Grinding and Polishing Related Pages

Related pages about Grinding and Polishing

Finishing process and Polishing process

We use different processing processes, processing conditions, and processing equipment to provide surfaces that meet customers’ requirements, such as pear finish, mirror finish, full surface finish, and partial finish.

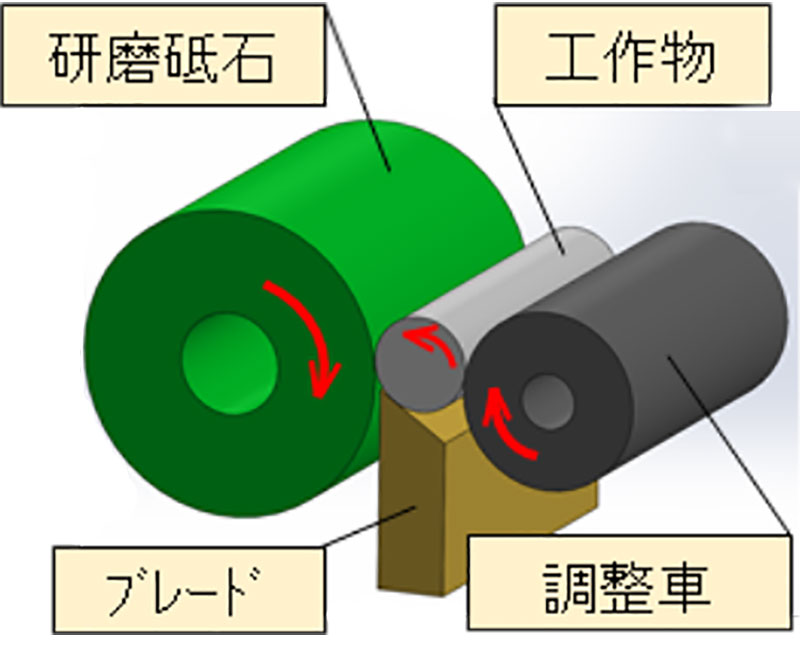

Centerless griding for fine wires and small tubes

Introducing centerless grinding for O.D. grinding of small-diameter pipes and long taper wire processing. It is possible to finish O.D. dimensions and surface roughness with high accuracy.

Nozzle assembly process

FUTA-Q is characterized by its ability to design, process, and assemble a wide variety of special material fine tubes in a single operation. The nozzle assembly process is introduced below.