HOME » FUTA-Q Technology » Bore polishing Surface treatment » I.D Polishing (Bore polishing/InternalPolishing)

I.D Polishing (Bore polishing/InternalPolishing)

I.D Polishing (Bore polishing/InternalPolishing)

update :

I.D Polishing

This section describes our I.D Polishing and mirror finishing techniques.

For example, mirror finishing of the inner surface of the pipe of the analysis nozzle prevents contamination adhesion and improves cleanability and analytical performance.

The Polishing Equipment is designed and manufactured by our R&D center in Kyoto Factory, and by experimenting with a variety of polishing methods tailored to pipe materials and component shapes,

we are accumulating internal polishing technologies.

I.D Polishing is our fundamental technique, which is essential for producing high-quality pipes for medical and analytical equipment.

It is possible to polish the inner surface of parts with complex shapes such as bending shapes, tapered shapes, and drawing nozzles, which are generally considered difficult to polish.

Method of polishing the inner surface of a small-diameter pipe

The list below shows the four pipe interior and part polishing methods available by FUTA・Q.

| Polishing method | Characteristics | Application | |

|---|---|---|---|

| Physical polishing | Fine tube polishing | Polishing method that directly polishes the inner surfaces of nozzle products and straight pipes with abrasive grains | Mass-produced products |

| Special polishing | Method of polishing the inner surface of curved pipes or tapered pipes | Mass-produced products | |

| Buffing | Method of polishing the internal surface of a short pipe with a product surface and an internal radius Φ4 or more. | Mass-produced products | |

| Chemical polishing | Suitable for parts of complex shapes. | Mass-produced products | |

Method of melting metal surface, electrolytic polishing has problems with uniform finishing because the electrode positions in the pipe are shifted.

Magnetic polishing requires a large-scale device and a number of processes to remove residual abrasive grains in a small-diameter pipe.

List of pipe materials small-diameter and abrasive specifications

The list below shows the specifications of I.D Polishing for small diameter pipes that can be mass-produced and available pipe lengths.

As there are many types of metal materials handled, some of them cannot be listed. So the table below shows standard sizes.

In addition to SUS, we can also handle difficult to cut materials such as titanium and cobalt alloys.

About metal materials and ultra-small pipes not shown in the table, please feel free to contact us.

| Materials of small-sized pipes (SUS304, SUS316L, β-titanium, pure titanium, MP35N※, ELGILOY*, etc.) | |||||||||

| Gauge (G) | Outside diameter(mm) | Tolerance(mm) | Internal Diameter(mm) | Tolerance (mm) | Length (mm) | Inner surface roughness (μm) | SUS | Ti | Co alloy |

|---|---|---|---|---|---|---|---|---|---|

| 26G | 0.45 | ±0.01 | 0.23 | 0.04 -0.02 |

230 | ≦Ra0.8 | 〇 | 〇 | ➖ |

| 25G | 0.51 | ±0.01 | 0.26 | 0.04 -0.02 |

230 | ≦Ra0.8 | 〇 | 〇 | ➖ |

| 24G | 0.55 | ±0.01 | 0.30 | 0.04 -0.02 |

230 | ≦Ra0.2 | 〇 | 〇 | ➖ |

| 23G | 0.63 | ±0.01 | 0.33 | 0.04 -0.02 |

230 | ≦Ra0.2 | 〇 | 〇 | ➖ |

| 22G | 0.71 | ±0.01 | 0.41 | 0.04 -0.02 |

230 | ≦Ra0.06 | 〇 | 〇 | ➖ |

| 21G | 0.81 | ±0.01 | 0.51 | 0.04 -0.02 |

480 | ≦Ra0.06 | 〇 | 〇 | 〇 |

| 20G | 0.88 | ±0.01 | 0.58 | 0.04 -0.02 |

480 | ≦Ra0.06 | 〇 | 〇 | 〇 |

| 19G | 1.06 | ±0.01 | 0.70 | 0.04 -0.02 |

480 | ≦Ra0.06 | 〇 | 〇 | 〇 |

| 18G | 1.26 | ±0.01 | 0.90 | 0.04 -0.02 |

480 | ≦Ra0.06 | 〇 | 〇 | 〇 |

| 17G | 1.48 | ±0.01 | 1.12 | 0.04 -0.02 |

480 | ≦Ra0.06 | 〇 | 〇 | 〇 |

| 16G | 1.61 | ±0.01 | 1.25 | 0.04 -0.02 |

480 | ≦Ra0.06 | 〇 | 〇 | 〇 |

| 15G | 1.81 | ±0.01 | 1.45 | 0.04 -0.02 |

480 | ≦Ra0.06 | 〇 | 〇 | 〇 |

| 14G | 2.11 | ±0.01 | 1.69 | ±0.04 | 480 | ≦Ra0.06 | 〇 | 〇 | 〇 |

| 13G | 2.41 | ±0.02 | 1.99 | ±0.04 | 480 | ≦Ra0.06 | 〇 | 〇 | 〇 |

| 12G | 2.76 | ±0.02 | 2.40 | ±0.04 | 480 | ≦Ra0.06 | 〇 | 〇 | 〇 |

| 11G | 3.06 | ±0.02 | 2.64 | ±0.06 | 480 | ≦Ra0.06 | 〇 | 〇 | 〇 |

| 10G | 3.4 | ±0.02 | 2.84 | ±0.06 | 480 | ≦Ra0.06 | 〇 | 〇 | 〇 |

| Wall thickness | 1.6 | ±0.01 | 0.60 | ±0.04 | 480 | ≦Ra0.06 | 〇 | 〇 | 〇 |

※ Cobalt-alloy MP35N® is a trademark of SPS Technologies.

※ Cobalt-alloy ELGILOY® is a trademark of Elgiloy Specialty Metals.

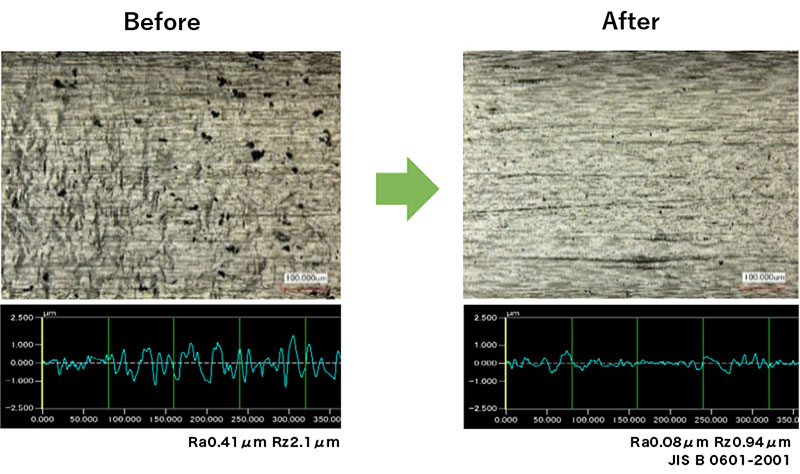

Results of I.D Polishing

I.D Polishing for pipes up to 700mm (bending pipe : max. 300mm) with the smallest bore diameter of φ0.1mm~ and surface roughness Ra0 of.01 is available.

In addition, complex shapes such as bending shapes, tapered shapes, and drawing parts of nozzles, which are usually difficult to be polished, can also be machined. I.D Polishing is applicable not only for SUS but also difficult-to-machine materials. Please feel free to contact us for more details.

・ Pipe Length: [Straight] up to 700mm [Bending] up to 300mm

・ Polishing inner diameter: minimum diameter φ0.1mm

・ Materials: SUS, titanium, titanium alloy, cobalt alloy, copper, etc.

・ Side roughness: Normal Ra0 of about.05 (Ra0.01 is also available)

New!

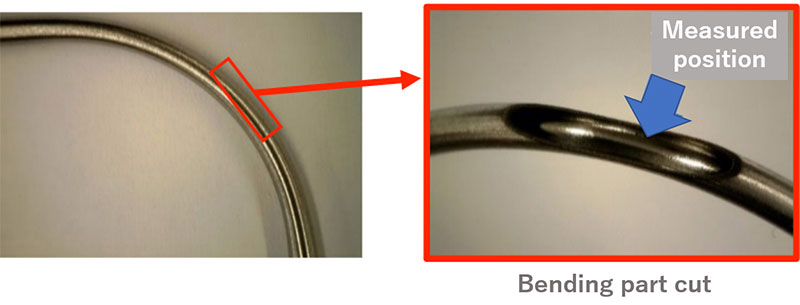

I.D Polishing for bent pipe

It is possible to remove wrinkles inside the internal radius generated during the bending process.

・ Size: ODφ1.35 IDφ1.11

・ Material: SUS316L

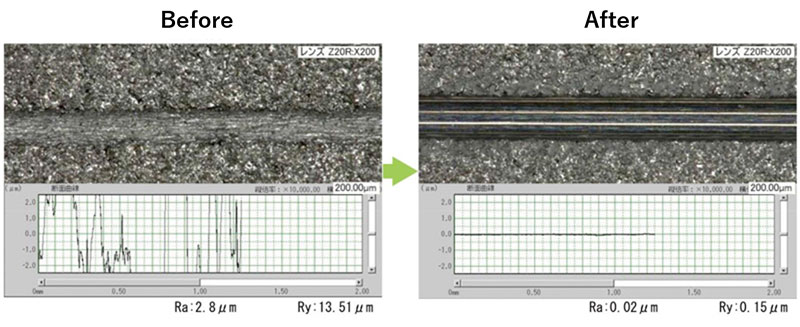

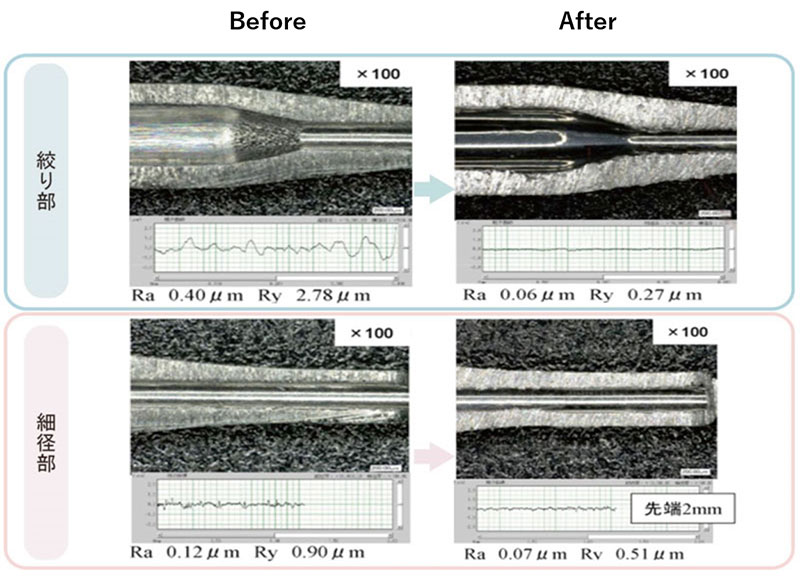

I.D Polishing for Swaging pipe

※ Applicable size: Pipes with an outer diameter of φ6 or less

Swaging pipes become thick at the time of processing, creating wrinkles and lowering inner the surface roughness. However, we have succeeded in the improving.

• Titanium Nozzle (DAT51)

Large radius ODφ1.82 IDφ1.08 Small radius ODφ0.96 ID0 51 Total length L=180

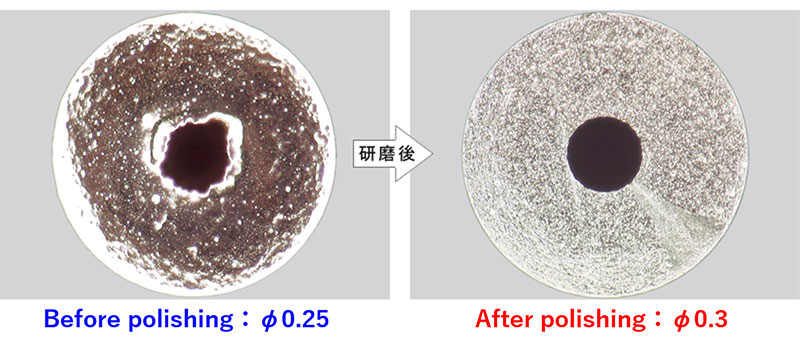

Cross section of commercially available small diameter pipe after I.D Polishing.

Enhancing roundness by Inner-Diameter Polishing

• SUS316Lφ1.6×φ0.25

Grinding and Polishing Related Pages

Related pages about Grinding and Polishing

Finishing process and Polishing process

We use different processing processes, processing conditions, and processing equipment to provide surfaces that meet customers’ requirements, such as pear finish, mirror finish, full surface finish, and partial finish.

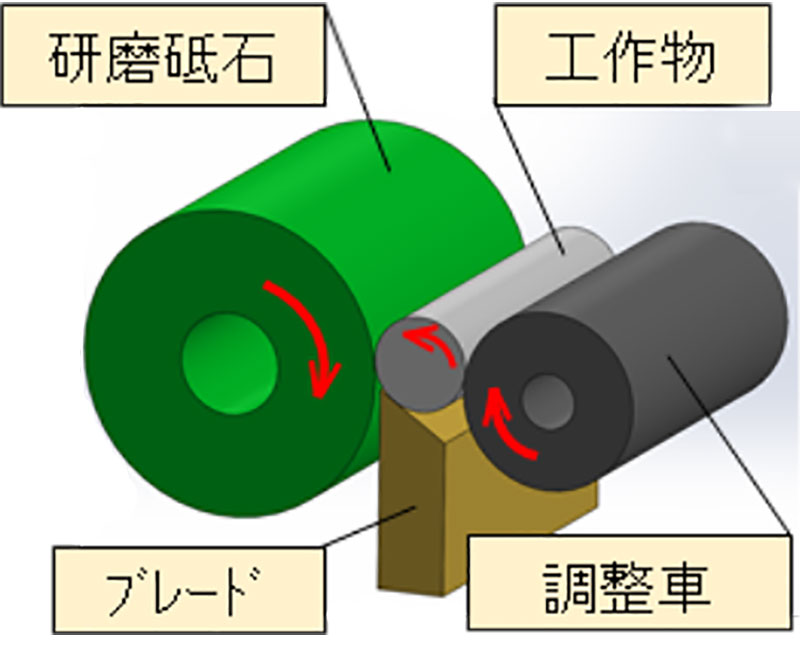

Centerless griding for fine wires and small tubes

Introducing centerless grinding for O.D. grinding of small-diameter pipes and long taper wire processing. It is possible to finish O.D. dimensions and surface roughness with high accuracy.

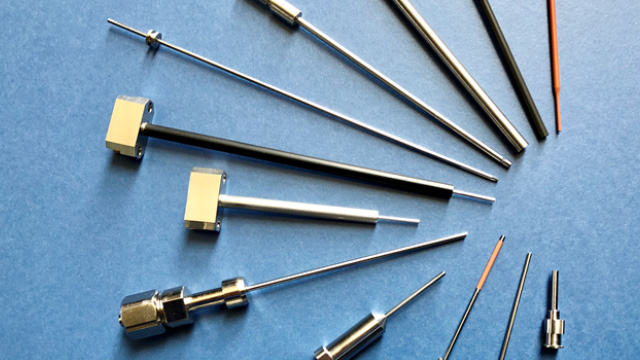

Nozzle assembly process

FUTA-Q is characterized by its ability to design, process, and assemble a wide variety of special material fine tubes in a single operation. The nozzle assembly process is introduced below.