HOME » FUTA-Q Technology » Guide wire manufacturing processes

Guide wire manufacturing processes

Guide wire manufacturing processes

update :

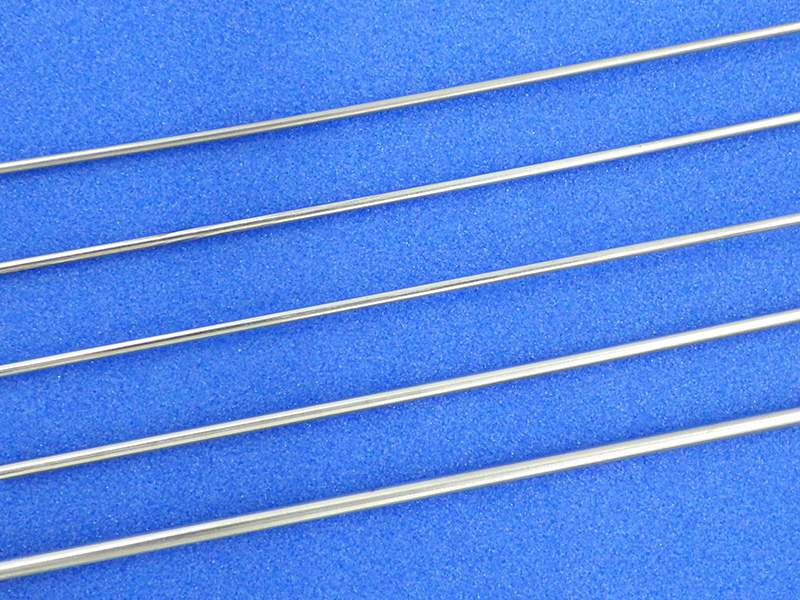

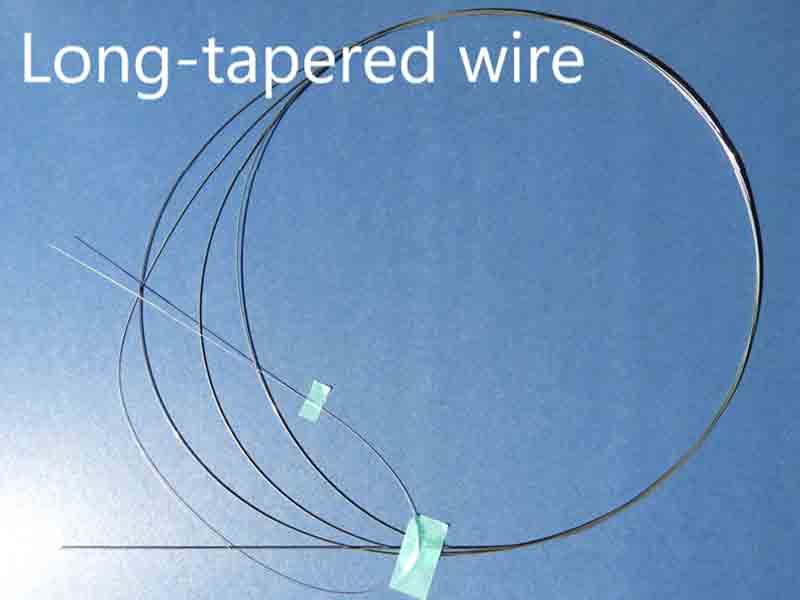

FUTA-Q has established a new production line in the clean environment in the second building of the Yagi Factory, located Nantan City in Kyoto. The line is to manufacture long-tapered wires used as a functional component such as a core wire of medical instruments including catheters or guide wires.

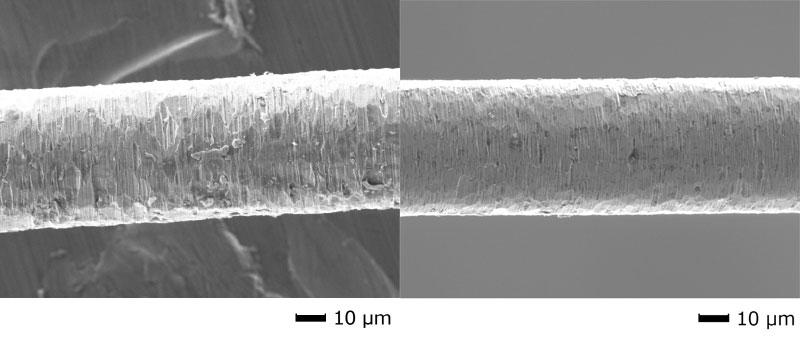

Into this dedicated line, we have introduced manufacturing facility such as a straightening machine, heat treatment furnace, centerless grinder, and self-made inspection device.

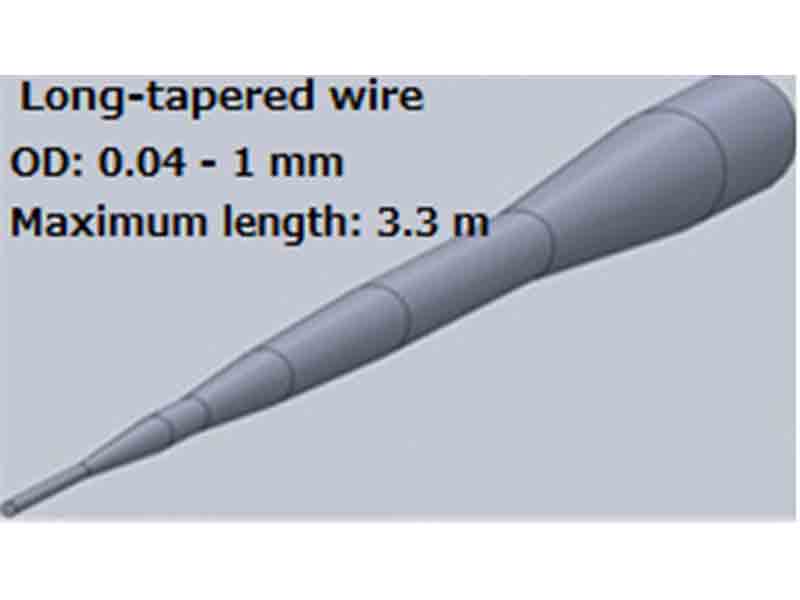

With these manufacturing equipment, multistage long-tapered wires with a cone shaped tapering point can be produced from a wire.

Processes such as jointing with a metal part or resin part, or coating are also available.

Long-tapered wire manufacturing processes

Please refer to the page indicated above on the processable size and precision.

(→side-scrolling)