HOME » FUTA-Q Technology » Inspection equipment » Micro-component discriminator “Kuraberuzo”

Micro-component discriminator “Kuraberuzo”

Micro-component discriminator “Kuraberuzo”

update :

FUTA・Q Precision produces a variety of fine medical parts that can be carried on fingertips.

It is too small to distinguish the difference between them in by the naked eye, and there is a risk of mixing up of different parts.

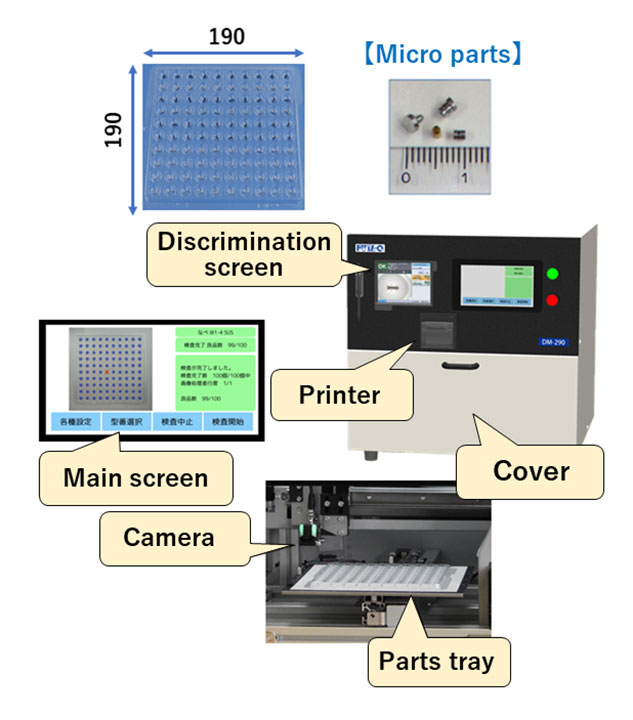

By recognizing the product position with the camera above, the inspection camera moves to the product position and magnifies the image, the product features are indexed, and the component shape is determined.

The camera can distinguish the appearance of all the small parts placed on the tray one by one.

Minute parts that can be distinguished

Material: SUS, Titanium, Plastics, etc.

Tray Size: External shape □190mm (right photo)

Determination part: Length 1 to 10mm

Pixel resolution: 0.013mm

Packaging form: using a tray that can contain containing 100 pieces

(discrimination quantity can be changed, camera detection)

Specification of the micro-component discriminator

● Equipment Dimensions 500W×515D×500H

● Top camera (for detecting two million pixels, part positions)

● Determination Camera (3.6 million pixels, with telecentric lens)

● Camera, Top, Bottom, Left, and Right 2 Axes Move + Parts, Front and Back Slide Table

● Safety switch with front cover

● Determination time 2 sec./pc. (including camera moving)

Operating method of the micro-component discriminator

(1) Select the part to be determined from the touch screen.

(2) Open the front cover and set the part tray.

(3) Close the cover and press “Start Test” on the touch screen.

(4) When auto determination process starts and ends, the determination results are are displayed on the screen.

(5) The determination results are printed and the part tray is taken out and completed.