HOME » FUTA-Q Technology » Bore polishing Surface treatment » Finishing process and Polishing process

Finishing process and Polishing process

Finishing process and Polishing process

update :

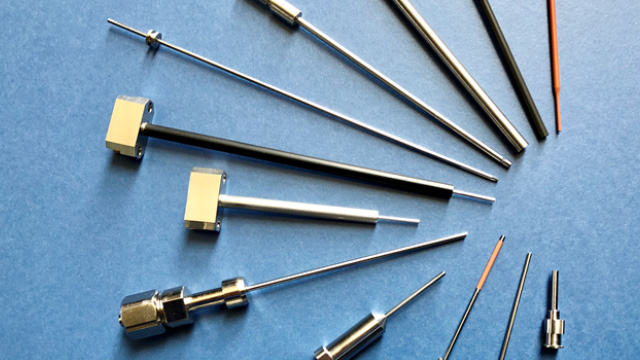

FUTA-Q always applies a best method selecting from different processing methods, processing conditions, and processing equipment to finish surfaces according to a client’s request, which includes satin, mirror, full-surface, and partial-face finishings.

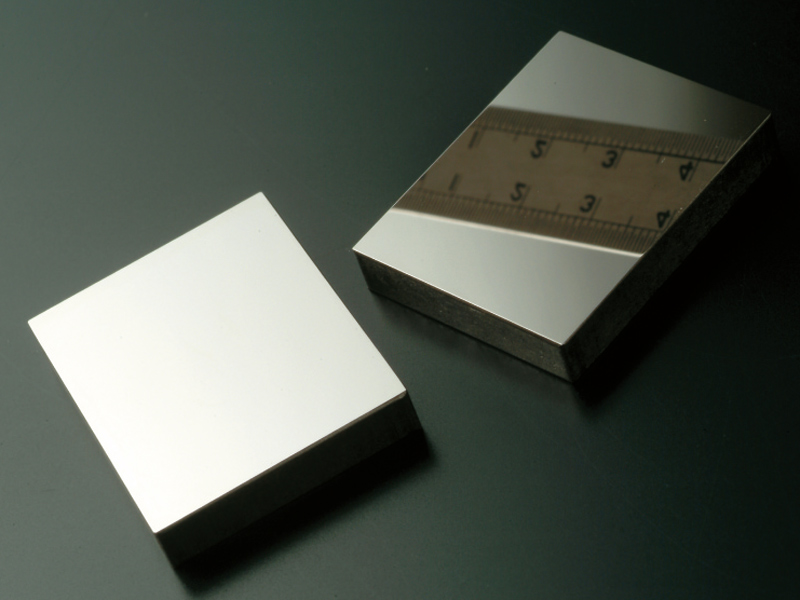

Mirror finishing

Mirror finishing is available for parts requiring tight sealing, such as joint surfaces and sliding surfaces of a selector valve, by using diamond powder of several micrometers in diameter and a special grinding lubricant.

Replacements of consumables such as a polishing pad and diamond powder is strictly controlled in accordance with data based on our experiences.

Lapping

Abrasive grains sprayed on the polishing plate of a lapping machine efficiently perform precise surface polishing.

Blasting

By spraying abrasive media such as alumina on a product surface, the surface can be finished to a satin finish.

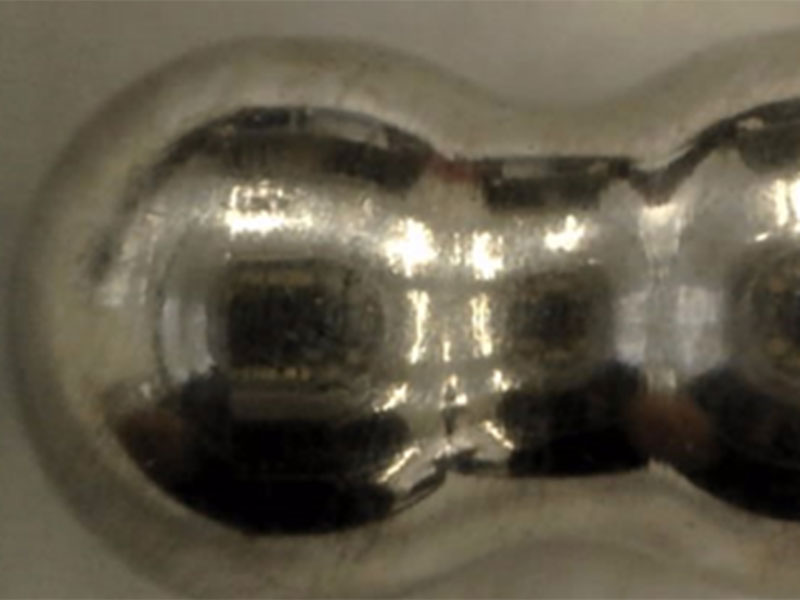

Aero-lapping

Elastic and flexible abrasives are used to minimize the damage to the substrate so that a mirror finish can be achieved even on a product with complex shape.

Electropolishing

Electropolishing after barrel polishing can make the edges of a product smooth.

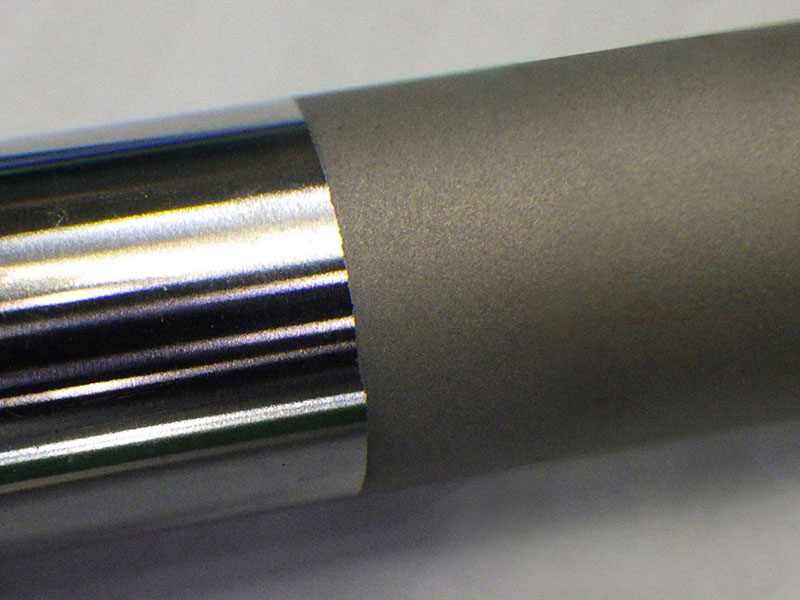

Burnishing

A burnishing tool is pressed against the product surface to polish it by crushing the uneven surface. For example, the connection area of pipe sealing component made of stainless steel can be finished to a surface hardness harder than HV330 and a surface roughness of Ra0.04.

Grinding and Polishing Related Pages

Related pages about Grinding and Polishing

I.D Polishing (Bore polishing / InternalPolishing)

小Introducing small-diameter pipe inner surface polishing and mirror finishing technologies.

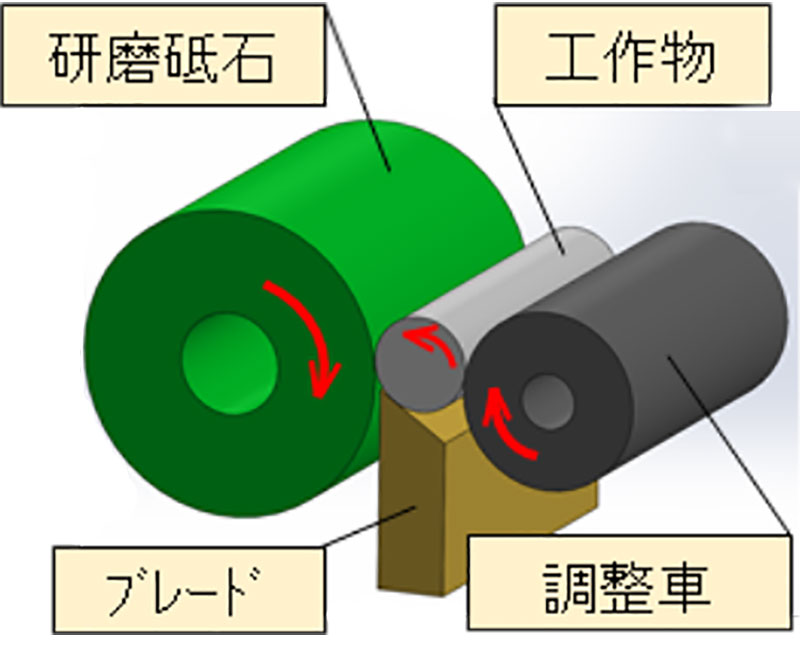

Centerless griding for fine wires and small tubes

Introducing centerless grinding for O.D. grinding of small-diameter pipes and long taper wire processing. It is possible to finish O.D. dimensions and surface roughness with high accuracy.

Nozzle assembly process

FUTA-Q is characterized by its ability to design, process, and assemble a wide variety of special material fine tubes in a single operation. The nozzle assembly process is introduced below.