Analysis changes. The world changes.

“High-performance materials × High-precision machining“

Case study01

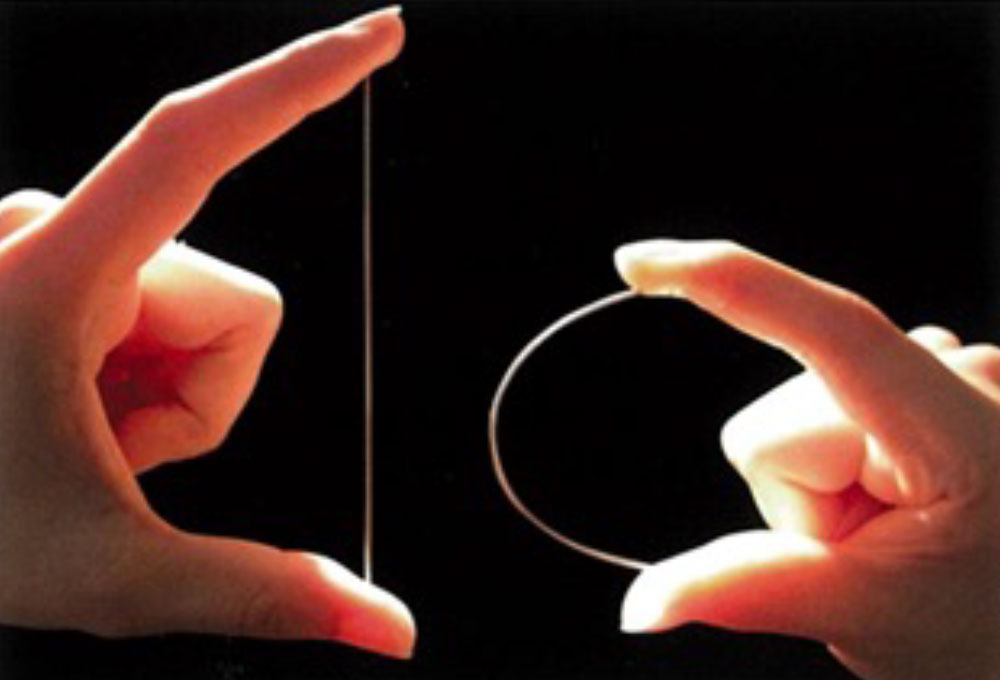

Special metal pipe

β-titanium alloy, NiTi alloy, CoCr alloy

For increasingly demanding performance requirements, utilizing small-diameter pipes made of special metals such as beta titanium may offer a solution.

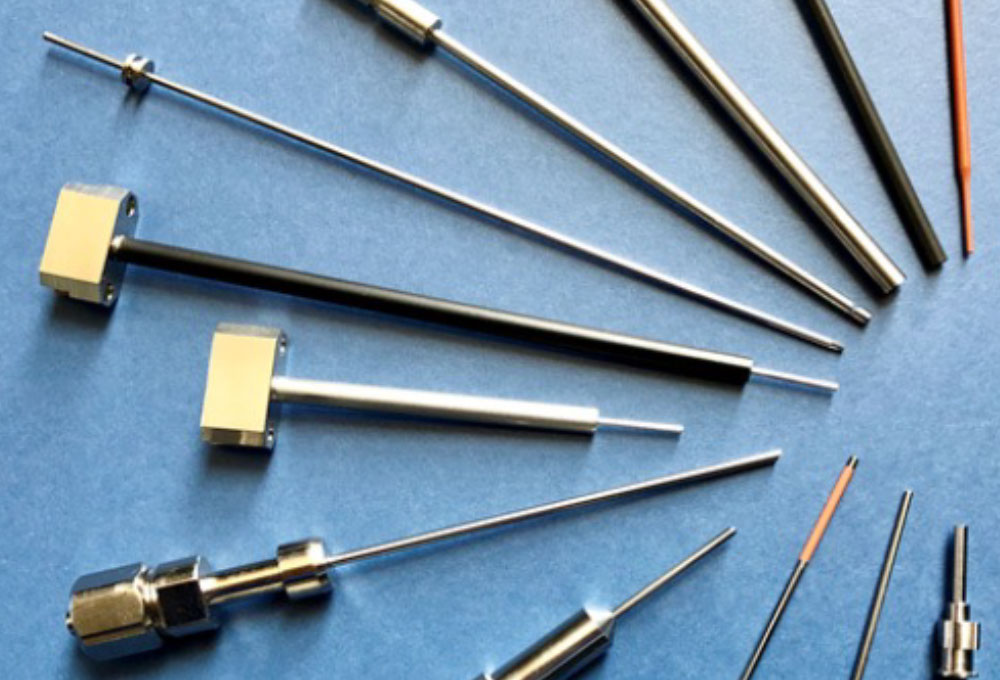

Case study02

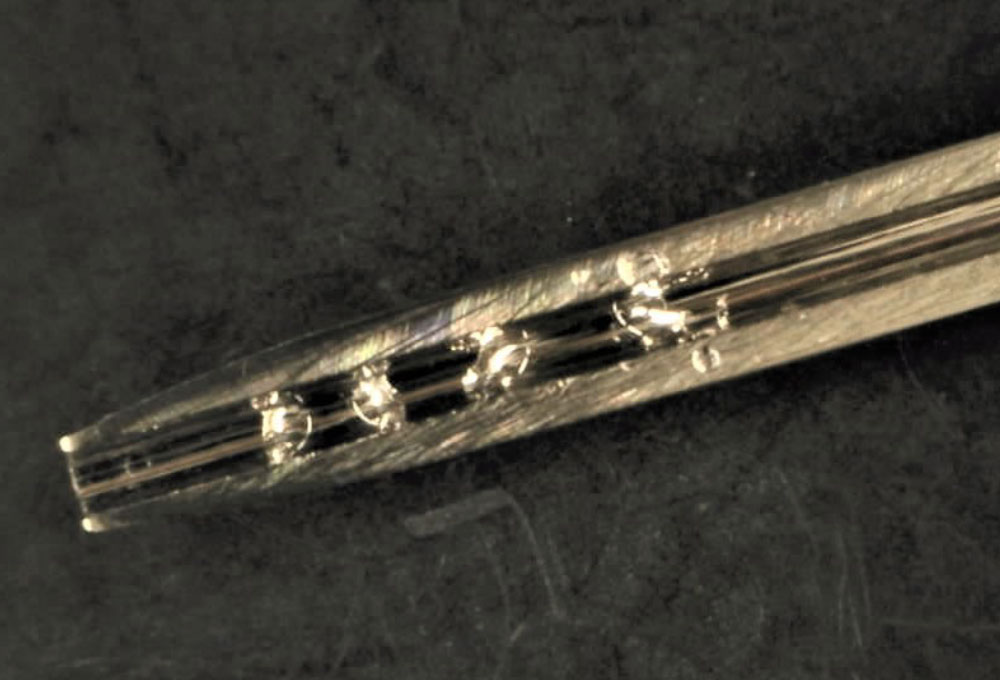

Nozzle, Needle Tip Processing

Lancet, Mengini, three-pronged needle, horizontal hole

We have a proven track record in manufacturing various nozzles, including complex multi-tube nozzles and side-hole-type needle tips with minimal chemical residue.

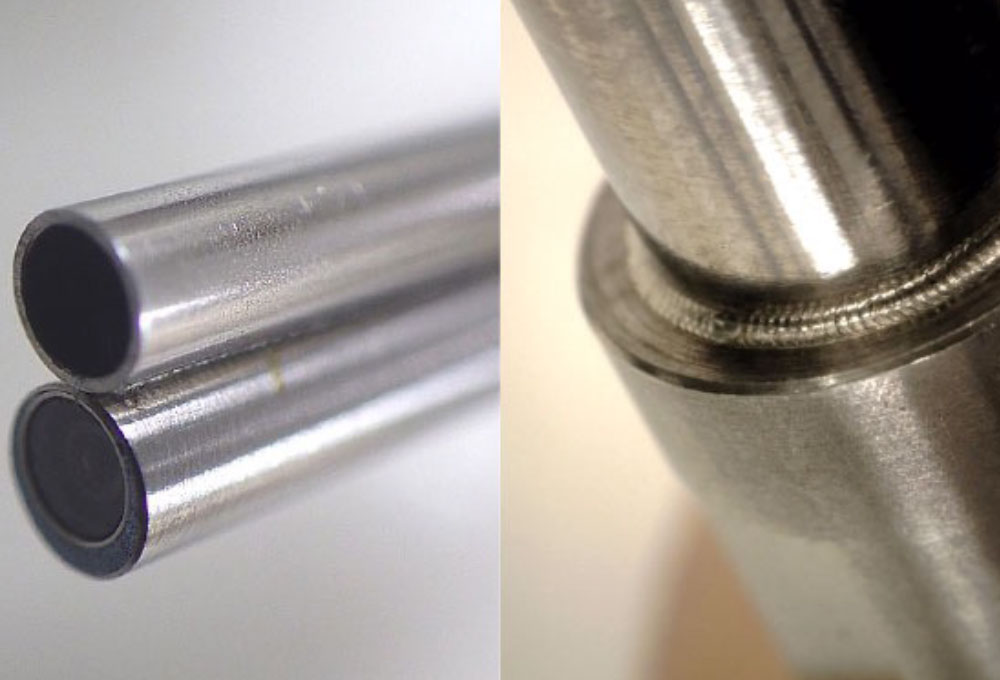

Case study03

Nozzle and Needle Assembly

Special-Shaped Nozzles, Welding, and Adhesion

We combine multiple laser welding machines and various joining technologies to meet the diverse needs of our customers.

Case study04

ノNozzle, Needle Internal Polishing

Straight grinding, taper grinding

Mirror polishing the inner surface of the analysis nozzle pipe suppresses contamination adhesion, improving cleanability and analytical performance.

Case study05

Fluorine Coating / Surface Treatment Processing

PTFE-coated / Ultra-thin fluoropolymer coating

Fluoropolymer coating prevents contamination from adhering to analytical instrument nozzles and devices. The image on the right shows a water-repellent coating applied to the inner surface of a nozzle.

Case study06

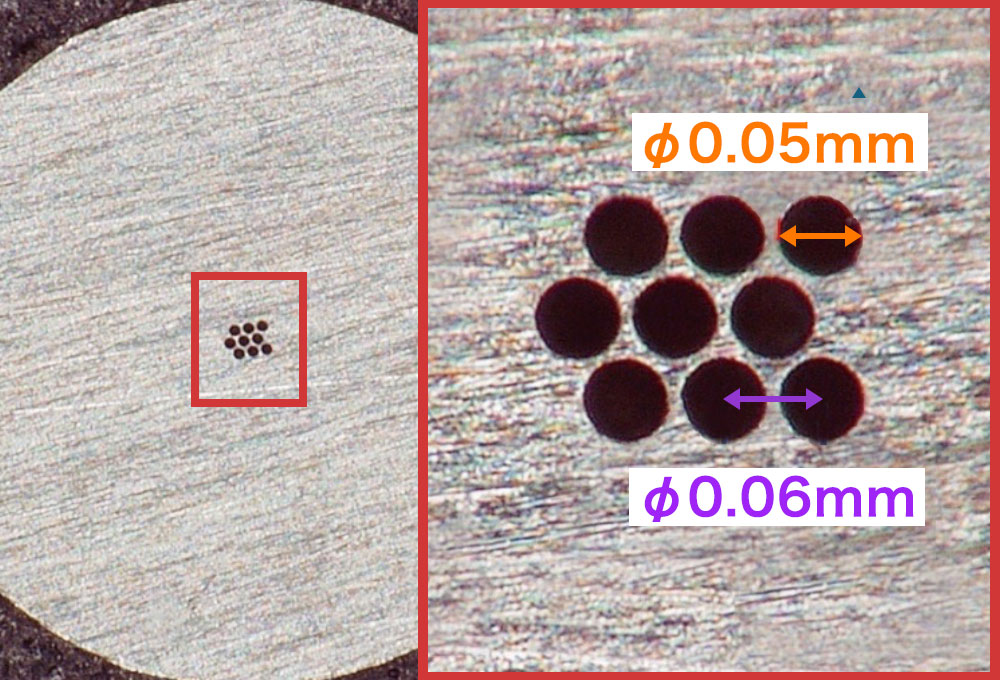

Precision Small-Diameter Deep Hole Machining

Precision Flow Path Components

To achieve “precision fluid channels” that accurately control fluids, it is necessary to precisely machine small-diameter deep holes and angled holes.

Case study07

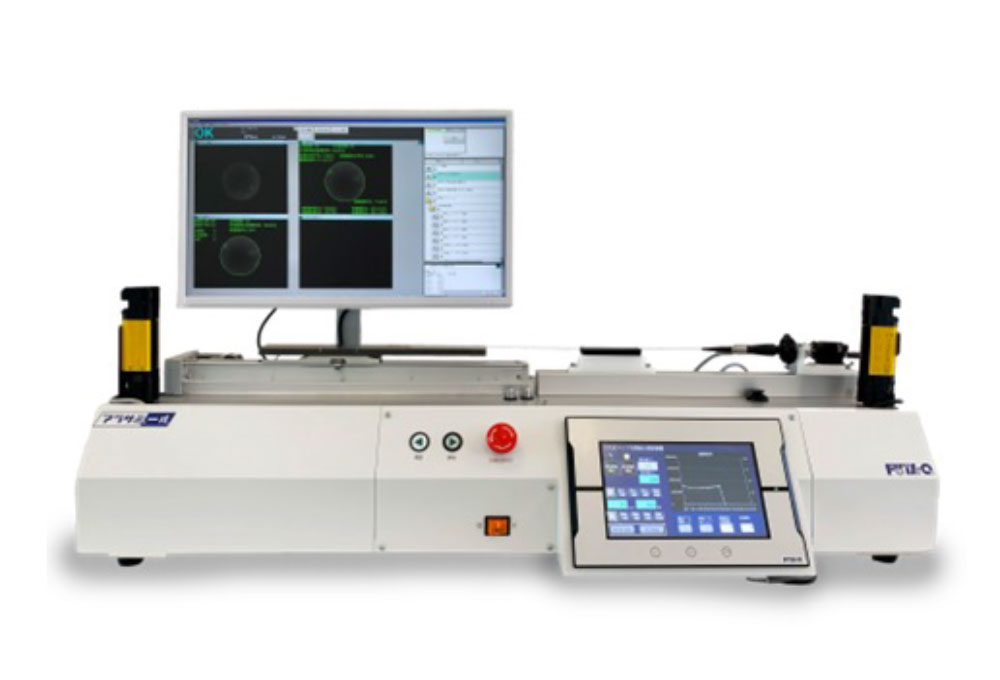

Small-Diameter Pipe Inspection and Measurement Proprietary Technology

Pipe Inspection and Measurement Technology

We have developed our own non-destructive device for measuring internal roughness.

We provide high-quality nozzle products that reach the inner surface of pipes.