Analytical Equipment

Analytical Equipment

Minimizing dead volume at a tip of needle or nozzle by our special pipe structure, inner surface polishing and surface treatment enable precise quantitative dispensation and high accurate analysis.

1) Joint surface of a device and pipe

Cutting marks or scratches on end surfaces can cause liquid leakage. FUTA-Q’s needles are finished for improving sealing performance, resulting no leakage.

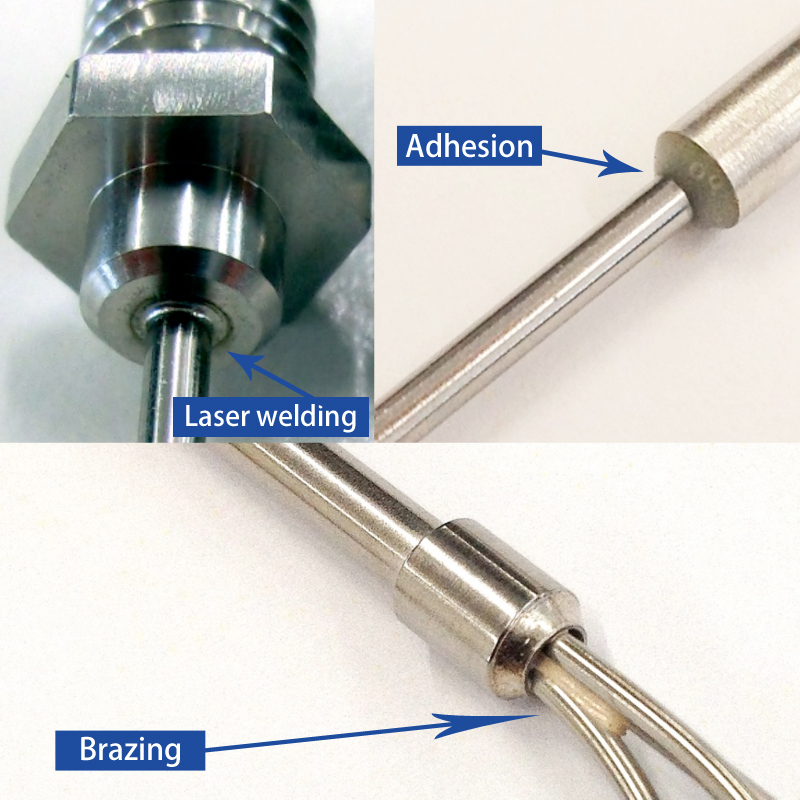

2) Part joining method

You can select the most favorable part joining method including laser welding, epoxy adhesion, brazing, and soldering.

3) Pipe making technology

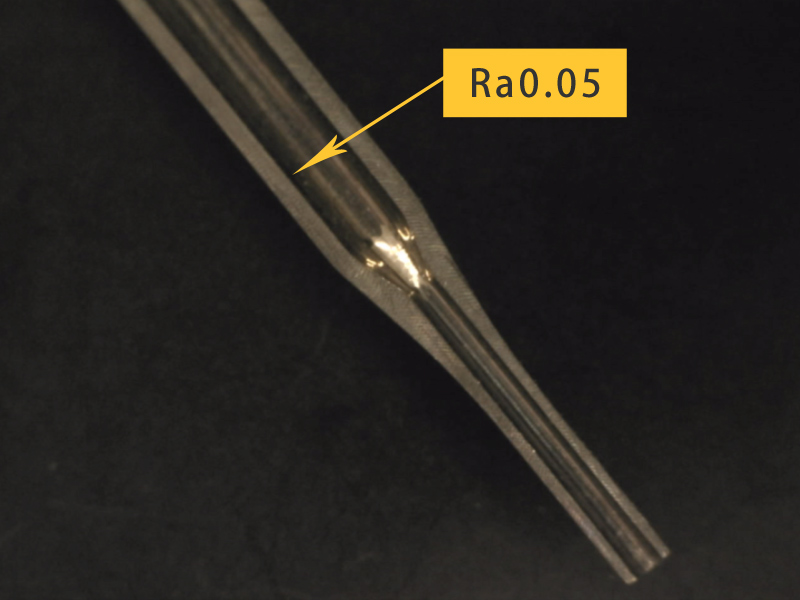

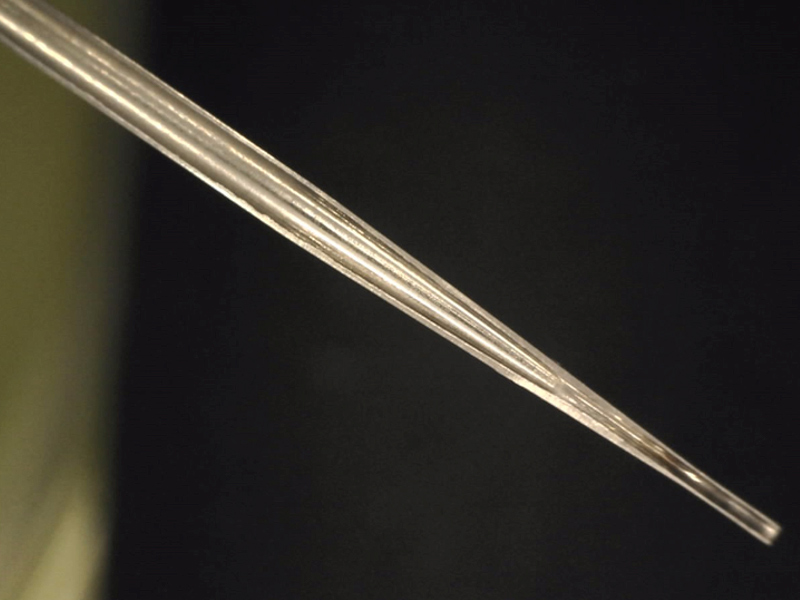

3)-1 Inner diameter polishing technology

(Applicable to difficult-to-cut materials such as SUS316L and Class 2-pure-titanium)

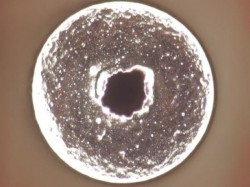

←【Before polishing】

←【Before polishing】

Inner shape of a small pipe on the market tends to be a distorted circle. Liquid of specimen often remains in roughness on the inner surface of the pipe even after washed, which sometimes prevents accurate analysis.

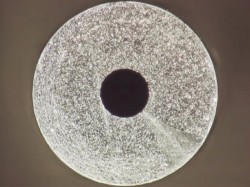

【After polishing】→

【After polishing】→

FUTA-Q employs inner diameter polishing process for improving circularity and smoothness so that easy cleaning of the inner surface is possible. This results in much less liquid residue for more precise quantitative analysis

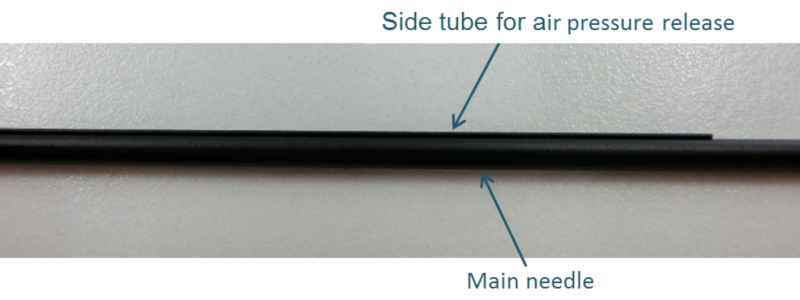

3)-2 Air pressure release technology (Air vent)

FUTA-Q offers two kind of air pressure release technology in which the inner pressure is adjusted to atmospheric pressure when aspirating a specimen from a sealed container such as an evacuated blood-collecting vessel, or when discharging it.

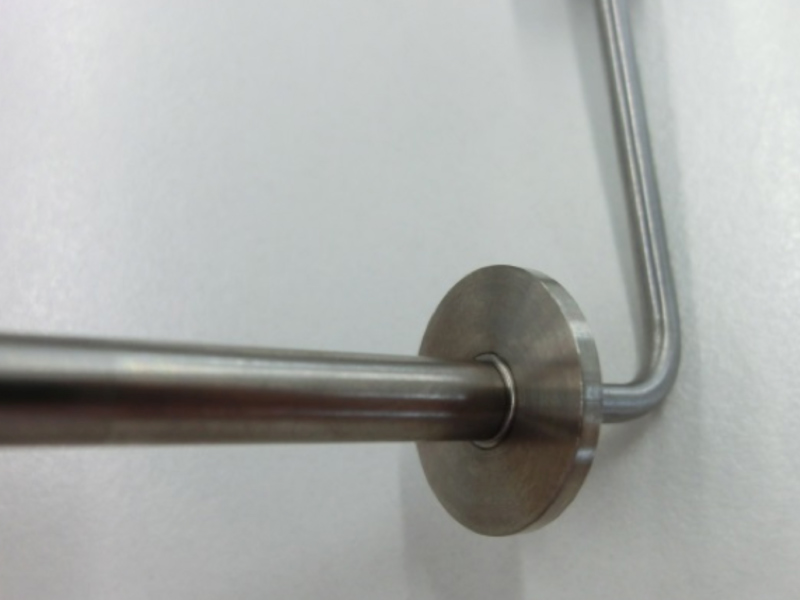

3)-2-1 Double needle structure

An air pressure release pipe is fixed to outside of a main needle pipe by welding or a similar way. This structure is applicable to any size you want.

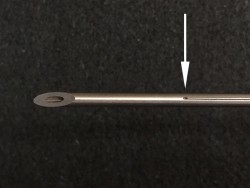

3)-2-2 Grooved needle structure

A groove is provided on a side of a needle pipe for releasing air pressure for preventing resistance during impalement of the needle.

3)-3 Bending process

3)-4 Improvement of draining and repellence

Drainability and repellency are improved with a special nozzle shaping (long taper) and various surface treatments. We propose coating such as PTFE, which has high insulation effect, and F2901, which is colorless transparent and 1μm or lower in thickness.

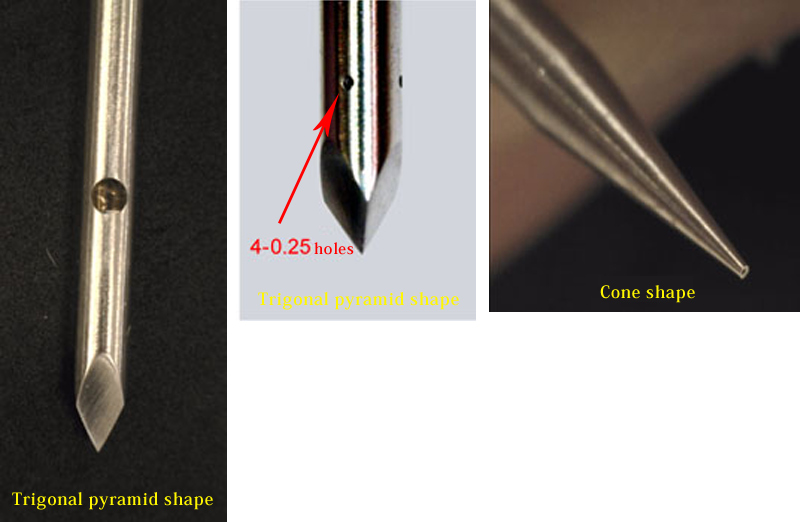

4) Tip processing technology

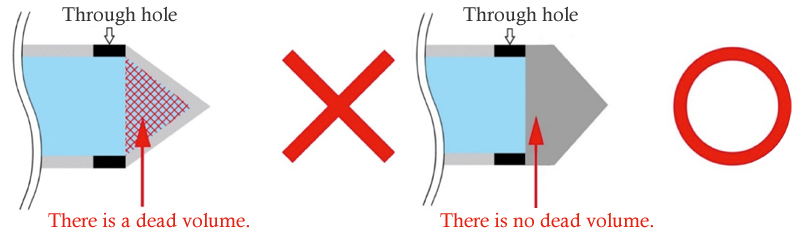

4)-1 Dead-volume free

A space inside a needle tip causes liquid residue in it, which is called dead-volume. This will cause contamination and deterioration of the analysis accuracy. FUTA-Q can manufacture needles without a dead volume at a needle tip by our unique technology.