HOME » FUTA-Q Technology » Surface Finishing » FC-180 (Thin Film Fluorine Coating)

FC-180 coat (thin-film fluoropolymer coat) - thin-film stain-resistant surface treatment coat!

FC-180 (Thin Film Fluorine Coating)

update :

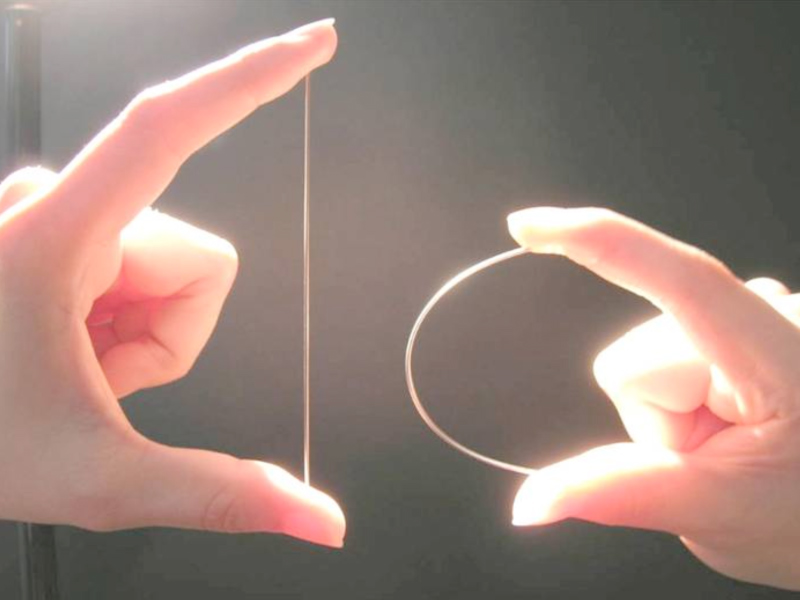

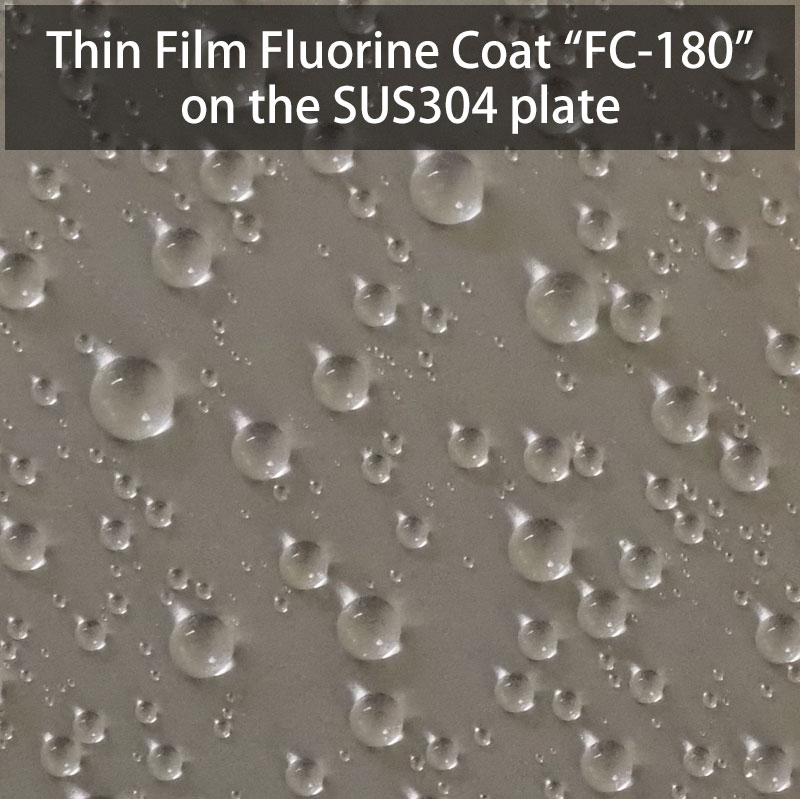

We have newly developed FC-180, a contamination-free surface coating, which can withstand repeated exposure to cleaning chemicals such as highly concentrated alkaline solutions. A metal surface usually has an affinity with water, alcohol, oil, or other liquids. A drop of alcohol on a metal surface, for example, will spread out on it.

Repelling alcohol inside a needle

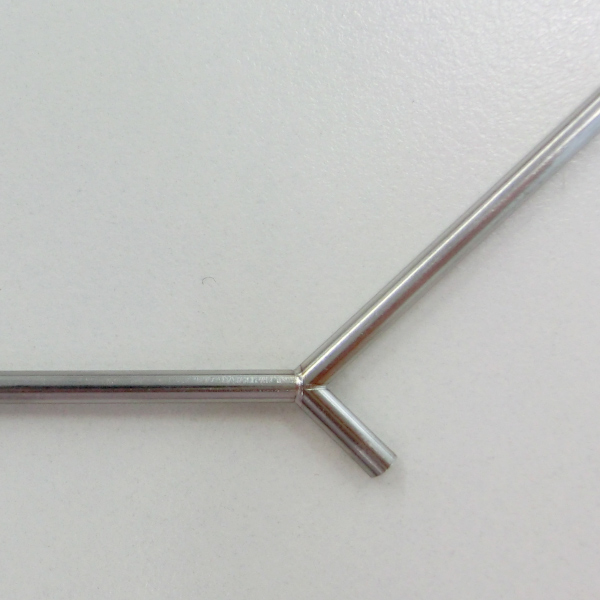

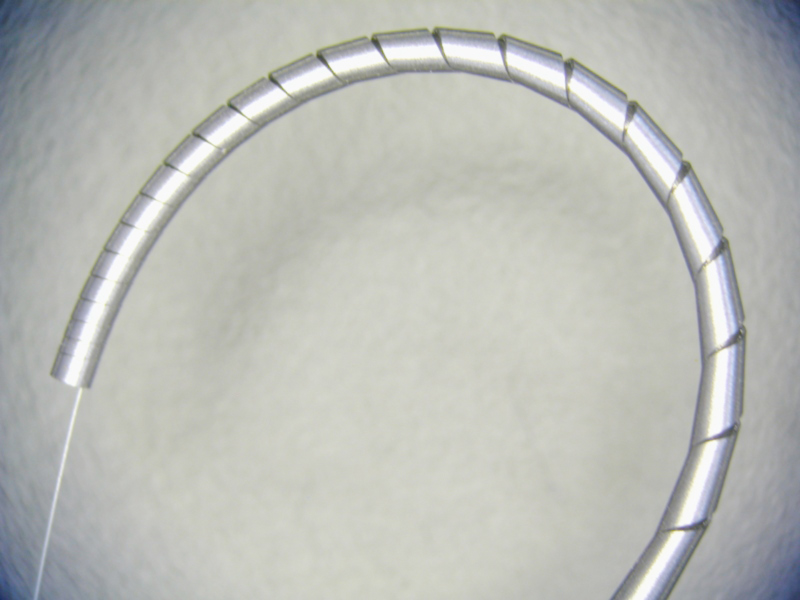

FC-180 coating forms a fluorine coat on the surface of a needle or micro channel to improve the water repellency and prevent a deposition of adhesives on the surface. FC-180 is a transparent fluorine coat with as thin as 1 μm or less in thickness and has water and oil repellency. It requires no changes in dimension of the current products. Please try this newly developed fluorine coating.

Features of FC-180

- – The coating has a thickness of submicron (<1 μm) which gives minimal dimensional effects on a work.

- – Uniform coating can be obtained on the inner surface of a pipe with about 0.3 mm in ID.

- – The firing process at a low temperature to form the coating layer gives no adverse effects on the works such as nozzles.

- – A transparent antifouling coating having high adhesiveness and hardness is formed.

- – The high chemical resistance of this coating allows your products to be repeatedly used.

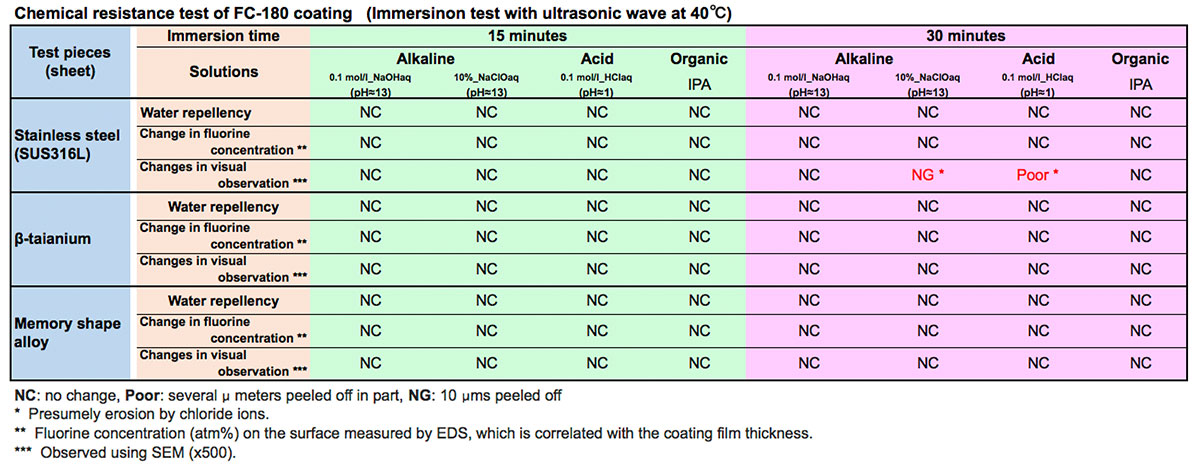

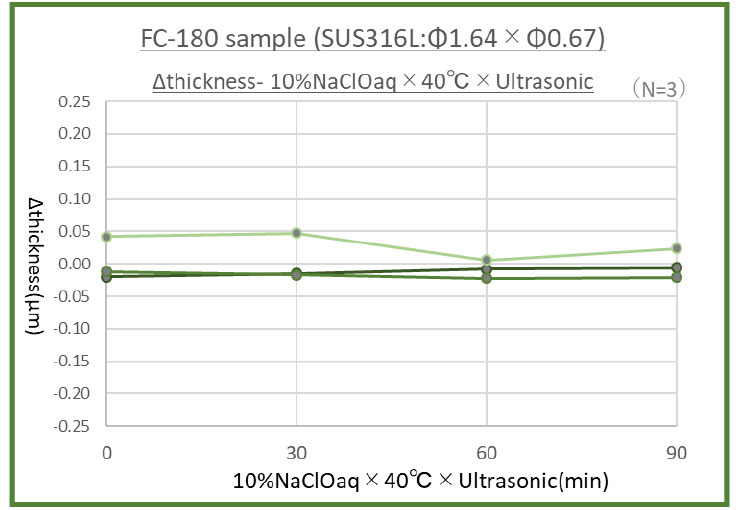

Evaluation of chemical resistance

Accelerated tests have been conducted to evaluate the durability of FC-180 against repeating washings using a highly concentrated alkaline solution.

【Evaluation method】

1.A specimen was immersed in 10% NaClOaq solution with ultra-sonic wave for accelerating the test effect to be observed for the surface conditions at every 30 minutes.

2.The thicknesses of the fluorine coats were calculated from the value obtained by the elemental analysis of an electronic microscope.

【Evaluation results】

Neither degradation nor thickness reducing was observed after dipping tests for 60 to 90 minutes with 10% solution of NaClO.

The sample surface shows no degradation of water- and oil-repellent properties, after immersed in 10% solution of NaClO for 60 minutes.

No thickness changes of the FC-180 coating were observed, after immersed in 10% solution of NaClO for 90 minutes.

Effectiveness of FC-180 thin film fluorine coating (with video clips)

Sprayed with isopropyl alcohol

↓Left half: non-coated

↓Right half: coated with FC-180

The right half coated with FC-180 obviously shows its excellent water-repellent property on which a droplet of alcohol makes a ball shape, while on the left half it spreads over on the surface.

Immersed in milk

↓Left half: non-coated

↓Right half: coated with FC-180

The right half coated with FC-180 shows its excellent draining property on which the milk falls apart from the surface quickly, while on the left half it remains on the surface.

Coating an inner surface of a nozzle with FC-180 allows you to easily remove the residual liquid inside the nozzle by air blowing because of its water/oil repellency. This will improve your cleaning workability and reduce contaminants inside nozzles.

Please contact us for details by phone and e-mail below.

» Contact Form

(Tel: +81-75-661-2931/Fax: +81-75-661-2937)

FC-180 Related pages