HOME » FUTA-Q e-mail magazine » news » FUTA-Q Technical Information 2022

FUTA-Q Technical Information 2022

FUTA-Q Technical Information 2022

update :

Dec. 20, 2022

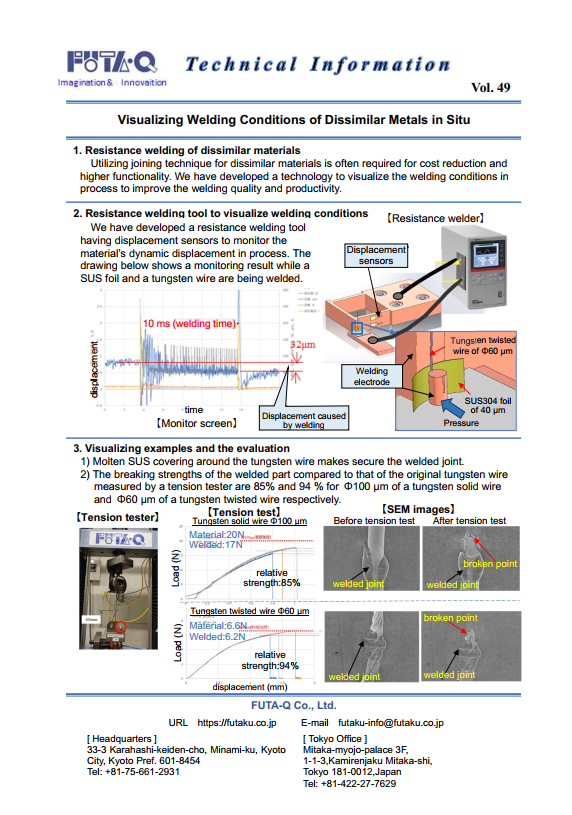

Visualizing Welding Conditions of Dissimilar Metals in situ

Resistance welding for jointing dissimilar materials has been required from many clients for increasing functionality and reducing the cost. We have developed a technology to visualize the welding conditions in process using displacement sensors. This visualization technology can improve the quality and productivity in resistance welding.

↓For the Technical Information Vol.49 in PDF

The Vol.49 of the Technical Information

Nov. 18, 2022

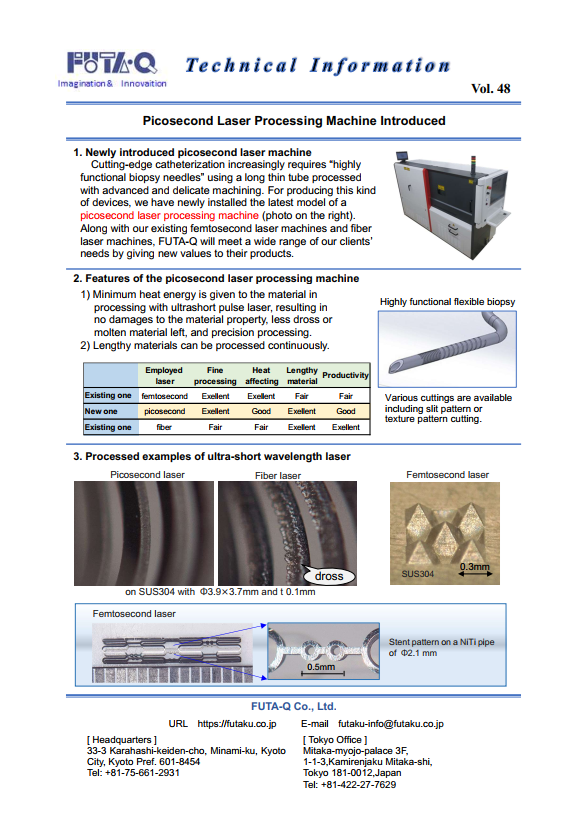

Picosecond Laser Processing Machine Introduced

Introducing the latest model of a “picosecond laser processing machine” allows us to process pipes or lengthy materials at high accuracy. This machine features the processing without thermal affect to the material by using ultra-short pulse laser, resulting in no damages to the material.

↓For the Technical Information Vol.48 in PDF

The Vol.48 of the Technical Information

July. 20, 2022

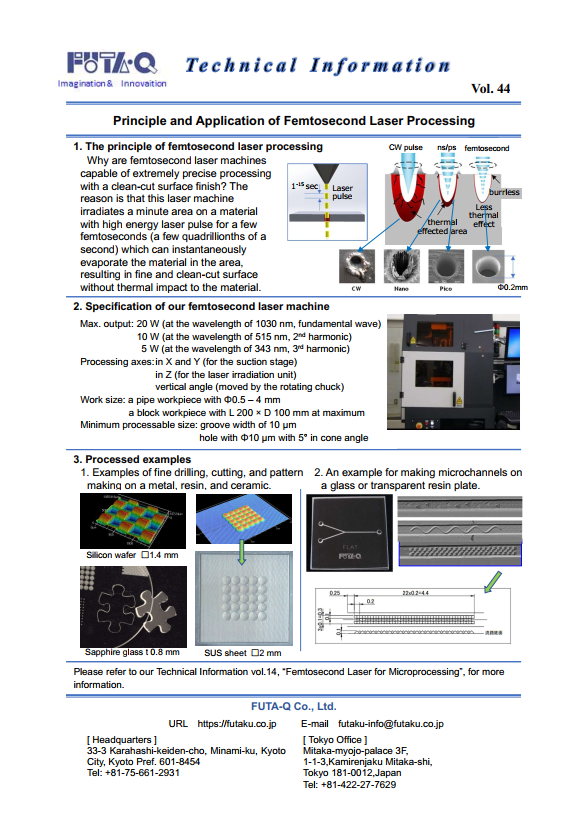

Principle and Application of Femtosecond Laser Processing

Why are femtosecond laser machines capable of extremely fine processing with clean cut surface finishes? You can find the answer and our solutions using our own femtosecond leaser machine.

↓For the Technical Information Vol.44 in PDF

The Vol.44 of the Technical Information

Apr. 20, 2022

FUTA-Q Install Additional Four CNC Combined-lathes

We have installed additional for CNC combined lathes which can continuously run for 24 hours with a bar-feeder and takeout mechanism. Difficult-to-machine materials can be also processed in micron order.

↓For the Technical Information Vol.41 in PDF

The Vol.41 of the Technical Information

Mar. 18, 2022

Mr. Eddy: Eddy-current Flaw Detector for Small Pipe

A small pipe having a thin wall can have a structure defect such as a crack, causing liquid leakage. We have developed the eddy-current flaw detector for small pipe, Mr. Eddy, for detecting this kind of defect which is invisible with a microscope.

↓For the Technical Information Vol.40 in PDF

The Vol.40 of the Technical Information

Feb. 18, 2022

Production of Long-taper Small Wires

The right images show a product sample of a long-taper small wire used as a core wire of medical equipment such as a catheter and a guide wire. For manufacturing this kinds of wires, FUTA-Q has set up the dedicated production line equipped with straightening machines, heat treatment furnaces, centerless grinders, and self-developed inspection tools.

↓For the Technical Information Vol.39 in PDF

The Vol.39 of the Technical Information

Jan. 20, 2022

Product/technology Analysis by Scanning Electron Microscope

This paper is showing the application examples of our SEM, scanning electron microscope which has an energy dispersive spectrometry (EDS) for quantitative analysis of elements, which are utilized for developing and improving our machining techniques, optimizing the production conditions, and certifying our products.

↓For the Technical Information Vol.38 in PDF

The Vol.38 of the Technical Information