At the foundation of a gentle world and prosperous future

Manufacturing that underpins energy and industry

Case study01

Machined parts made from difficult-to-cut materials

Titanium, Hastelloy, Inconel materials

Demand is growing for difficult-to-machine materials with high functionality, such as heat resistance and corrosion resistance. We perform high-precision machining on these high-performance components.

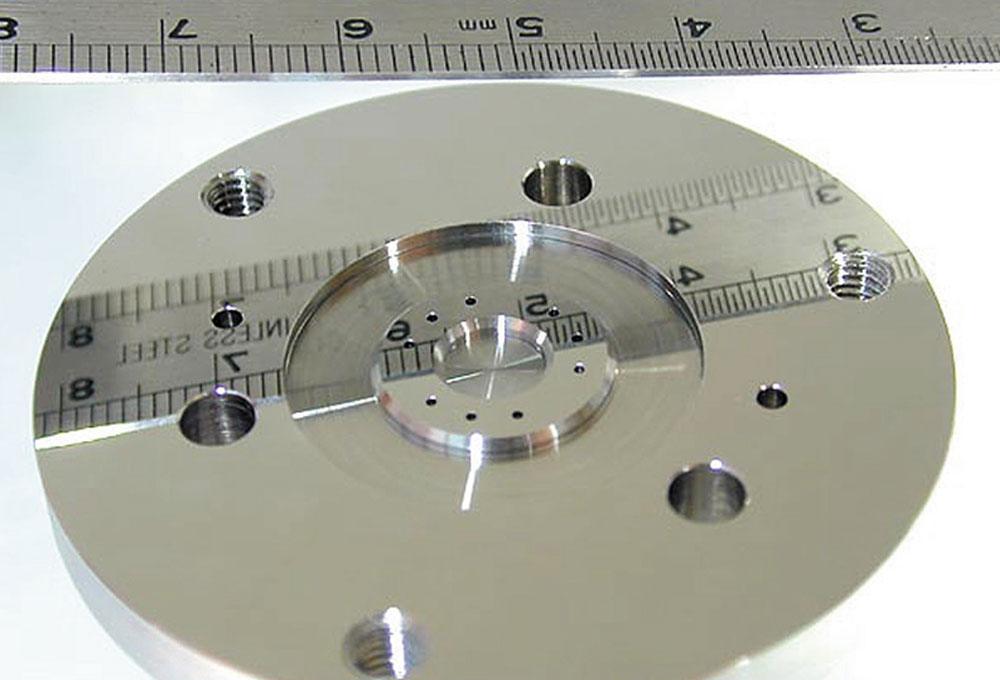

Case study02

Precision CNC Turning

H-rule fittings and flanges

We have extensive experience in lathe machining. We operate a fleet of 42 machines, including the latest multi-tasking CNC lathes and Swiss-type CNC lathes.

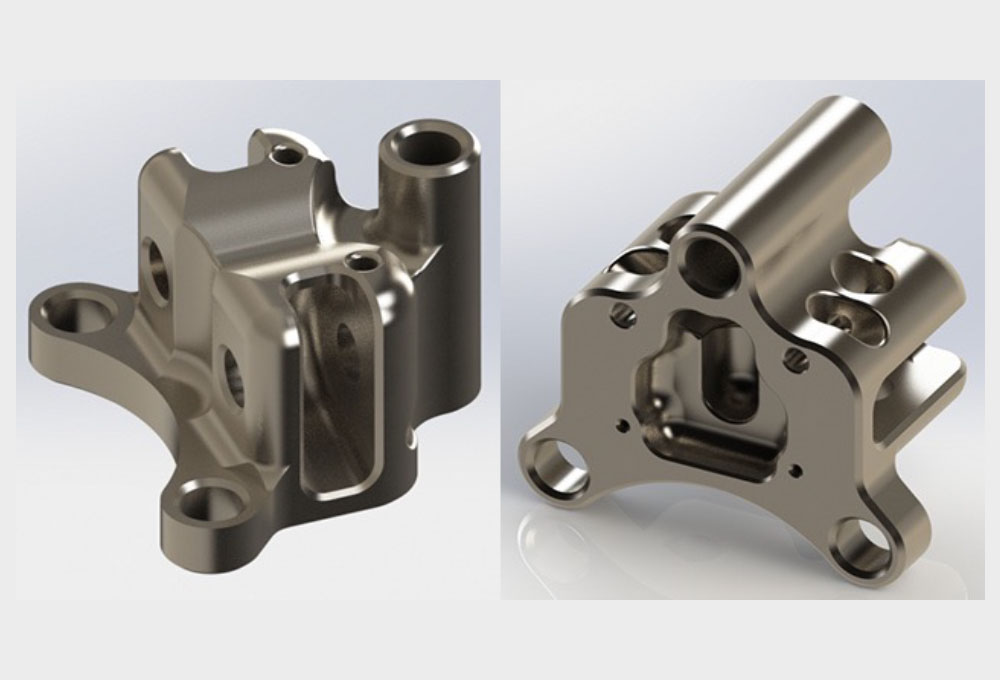

Case study03

Precision Machining

Flow Path Block · Building Block

We specialize in high-precision machining of complex-shaped parts made from difficult-to-machine materials using 3D simulation technology.

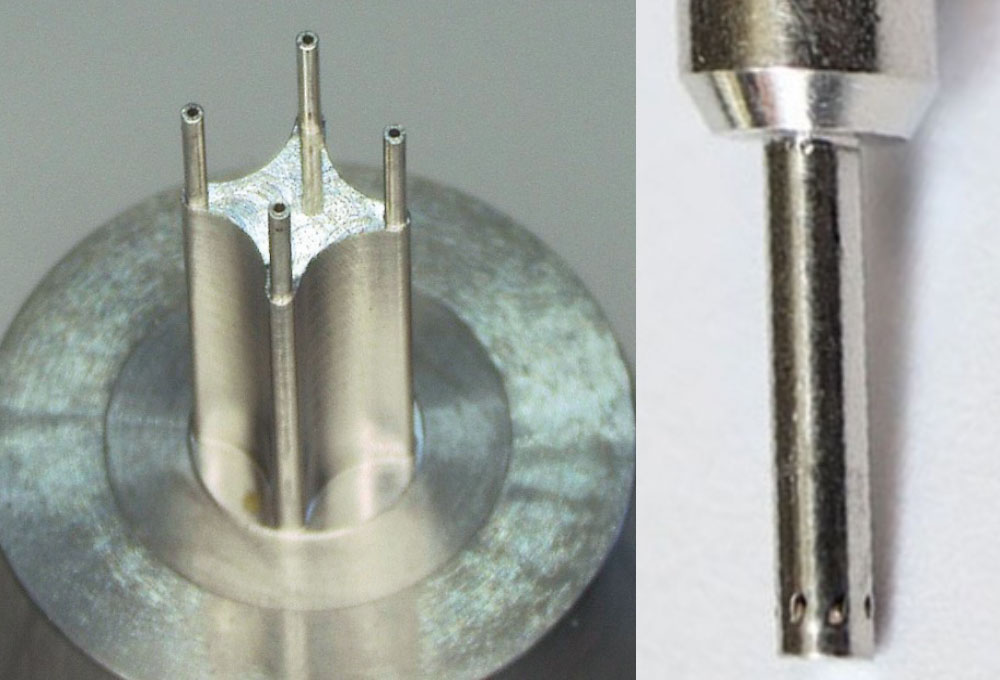

Case study04

Part joining and assembly

Special-Shaped Nozzle (Spray Nozzle, Multiple Holes)

For joining precision parts, straight and rotary laser welding produces a clean finish. For relatively large parts, TIG welding excels.

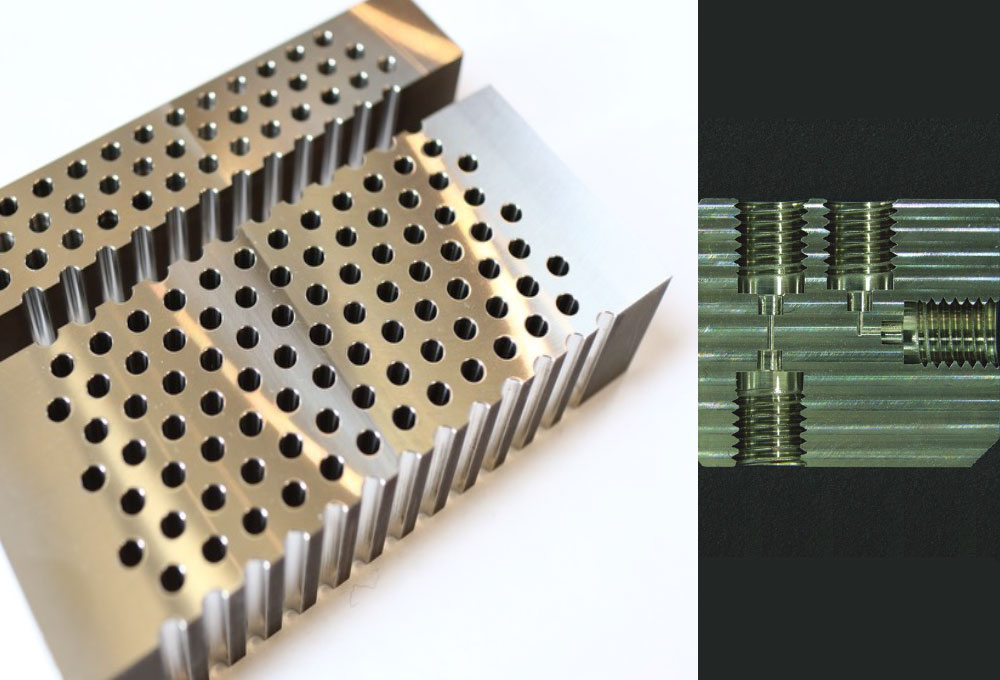

Case study05

Precision Small-Diameter Deep Hole Machining

Precision flow path components

We have extensive experience in lathe machining. We maintain a fleet of 42 machines, including the latest multi-tasking CNC lathes and Swiss-type CNC lathes.

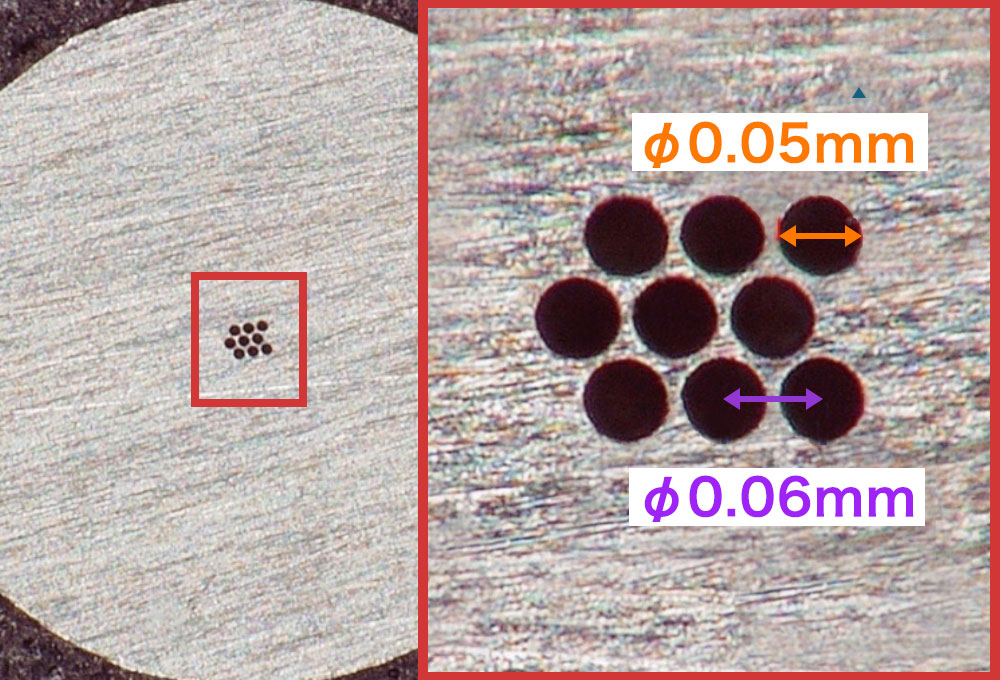

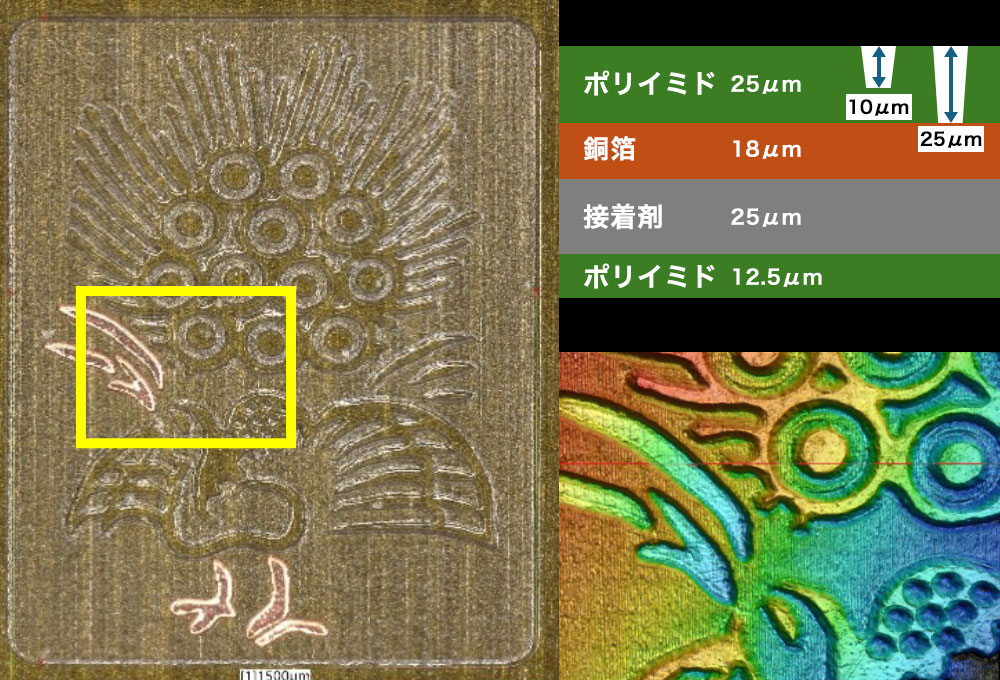

Case study06

Ultra-short pulse laser processing

Precision Pattern & Micro Hole Drilling

We possess hybrid processing machines combining excimer and femtosecond lasers, as well as picosecond laser processing machines capable of continuous processing from long materials.

Case study07

Precision finishing and polishing (mirror finish)

Wrapping Blast Vanishing

We achieve the required finish, from flat grinding using abrasive particles sprayed onto a lap plate to buff finishing under a microscope.