HOME » FUTA-Q e-mail magazine » news » FUTA-Q Technical Information2023

FUTA-Q Technical Information2023

FUTA-Q Technical Information2023

update :

Dec. 20, 2023

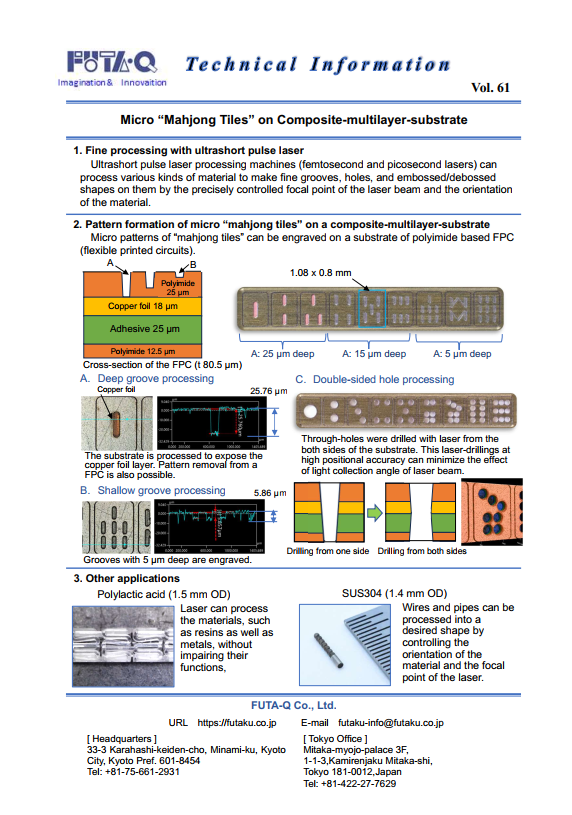

Micro “mahjong tiles” on a composite-multilayer-substrate

Ultrashort pulse laser processing machines (femtosecond and picosecond lasers) can process various kinds of material to make fine grooves, holes, and embossed/debossed shapes on them by the precisely controlled focal point of the laser beam and the orientation of the material.

↓For the Technical Information Vol.61 in PDF

The Vol.61 of the Technical Information

Nov. 20, 2023

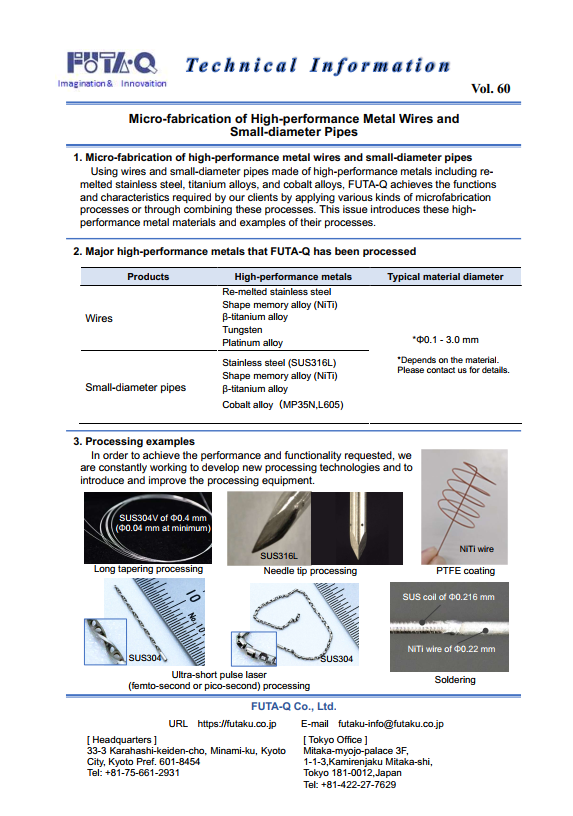

Micro-fabrication of high-performance metal wires and small-diameter pipes

Using wires and small-diameter pipes made of high-performance metals, FUTA-Q achieves the functions and characteristics required by our clients by applying various kinds of microfabrication processes or through combining these processes. This issue introduces these high-performance metal materials and examples of their processing.

↓For the Technical Information Vol.60 in PDF

The Vol.60 of the Technical Information

Oct. 20, 2023

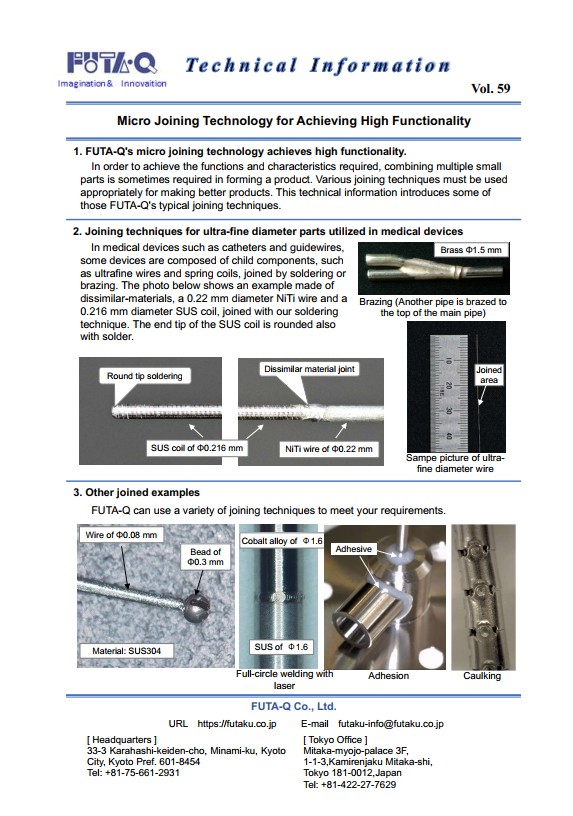

Micro joining technology for achieving high functionality

In order to achieve the functions and characteristics required, combining multiple small parts is sometimes required to form a product. Various joining techniques must be used appropriately for better products. This technical information introduces some of FUTA-Q’s typical joining techniques.

↓For the Technical Information Vol.59 in PDF

The Vol.59 of the Technical Information

Aug. 21, 2023

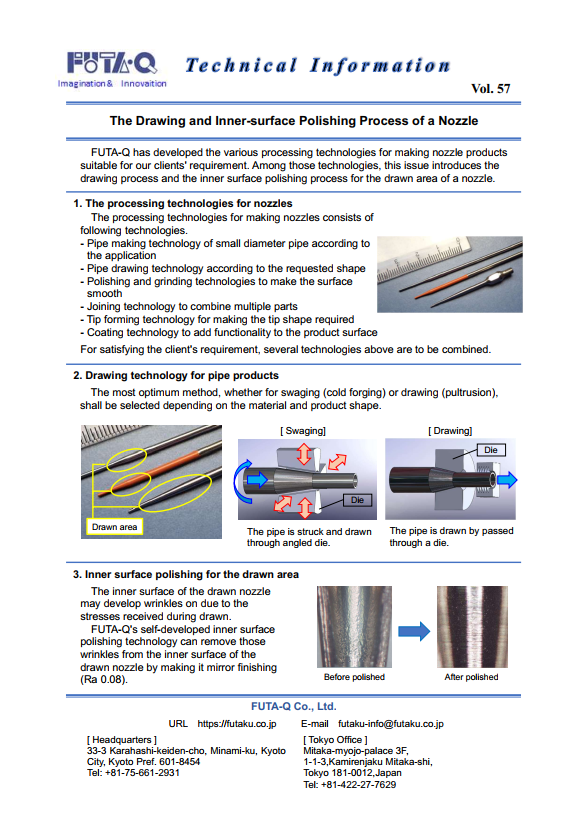

The drawing and inner surface polishing process of a nozzle

FUTA-Q has developed the various processing technologies for making nozzle products to meet our clients’ requirement. Among them, this issue introduces the drawing process and the inner surface polishing process for the drawn area of a nozzle.

↓For the Technical Information Vol.57 in PDF

The Vol.57 of the Technical Information

Mar. 20, 2023

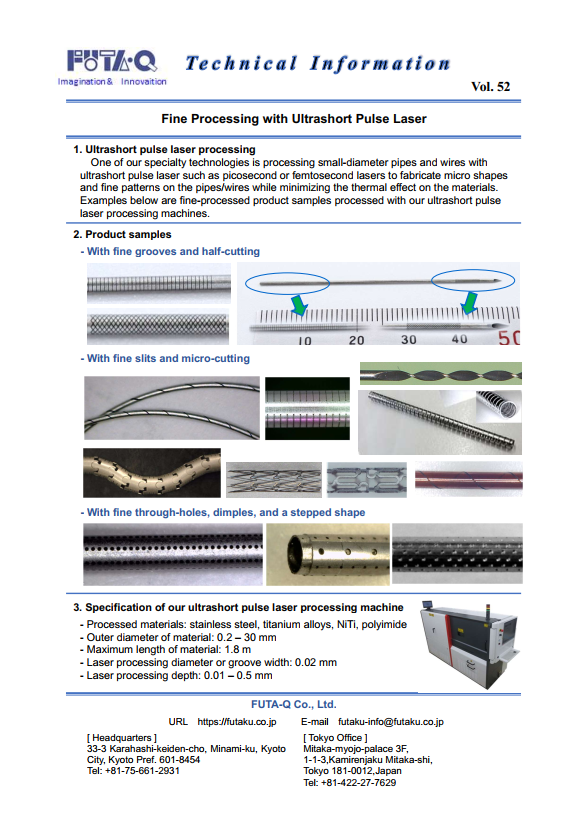

Fine processing with ultrashort pulse laser

This issue introduces the process for small-diameter pipes and wires with ultrashort pulse laser processing machines such as picosecond or femtosecond lasers to make micro shapes and fine patterns on the pipes/wires while minimizing the thermal effect on the materials.

↓For the Technical Information Vol.52 in PDF

The Vol.52 of the Technical Information

Jan. 20, 2023

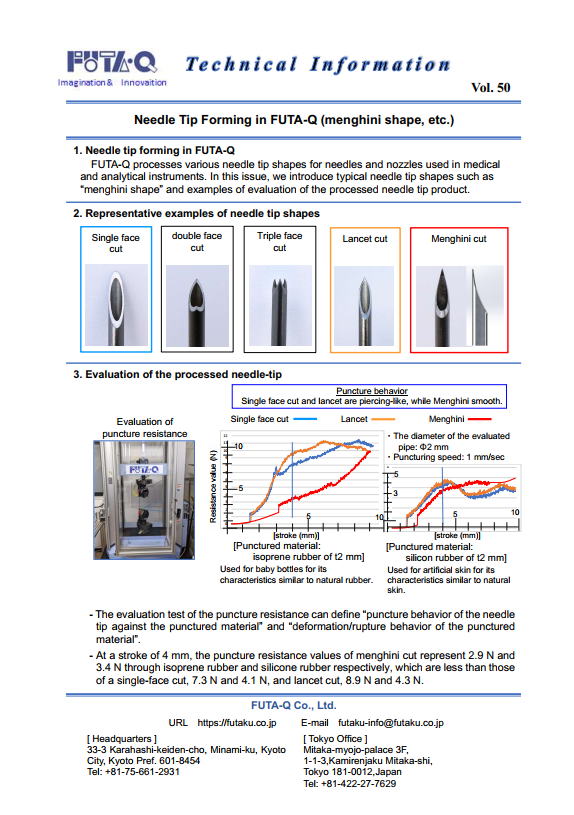

Needle Tip Forming in FUTA-Q (menghini shape, etc.)

FUTA-Q processes various needle tip shapes for needles and nozzles used in medical and analytical instruments. In this issue, we introduce typical needle tip shapes such as “menghini shape” and examples of evaluation of processed needle tip products.

↓For the Technical Information Vol.50 in PDF

The Vol.50 of the Technical Information