HOME » FUTA-Q Technology » Nozzle assembly process

Nozzle assembly process

Nozzle assembly process

update :

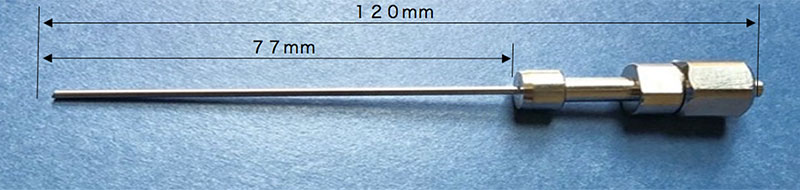

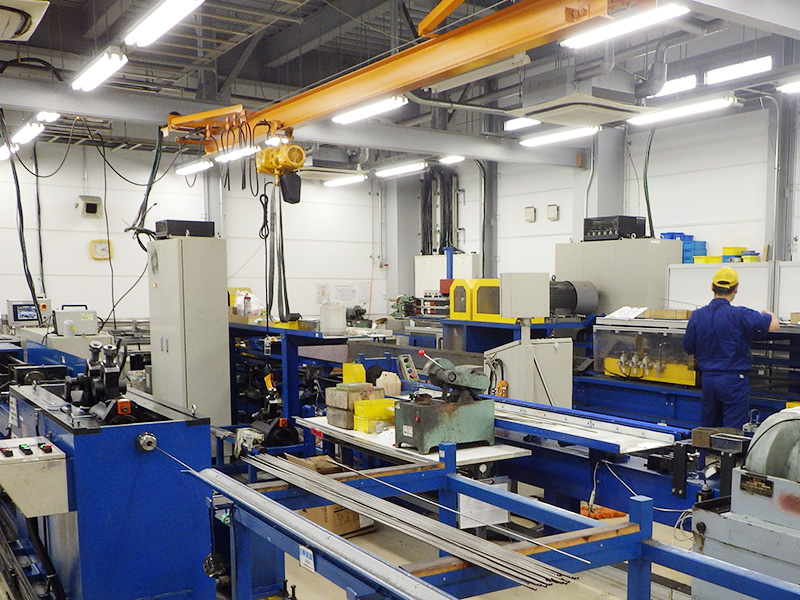

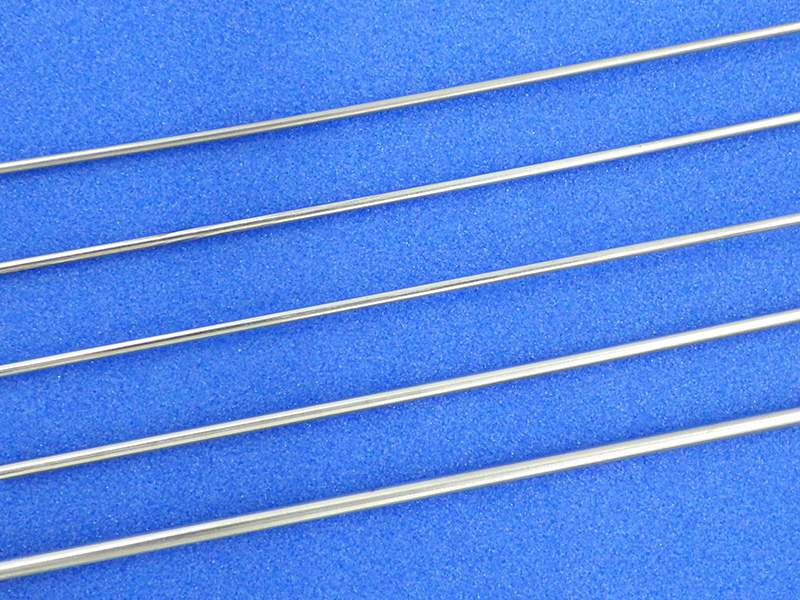

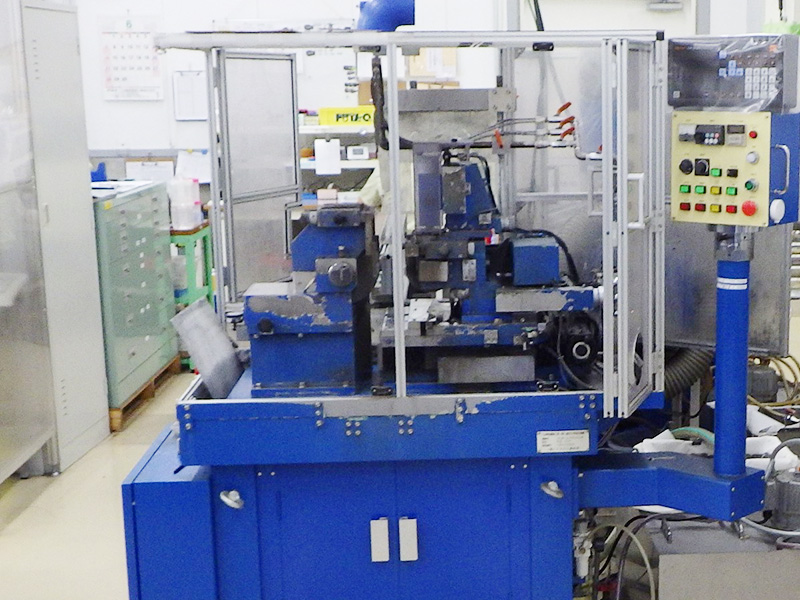

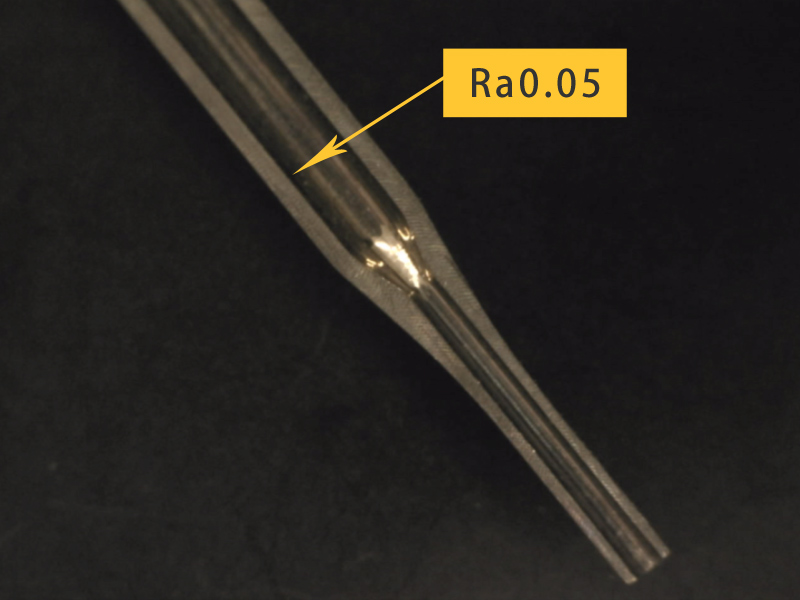

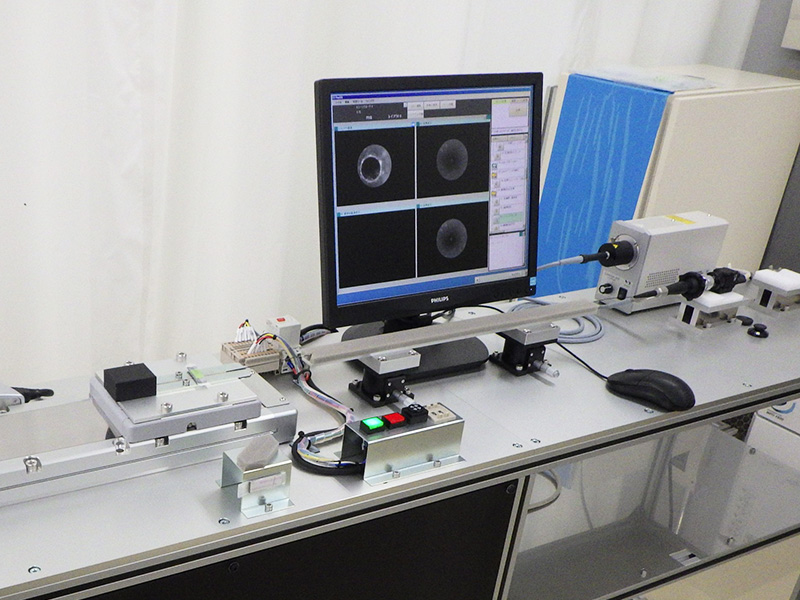

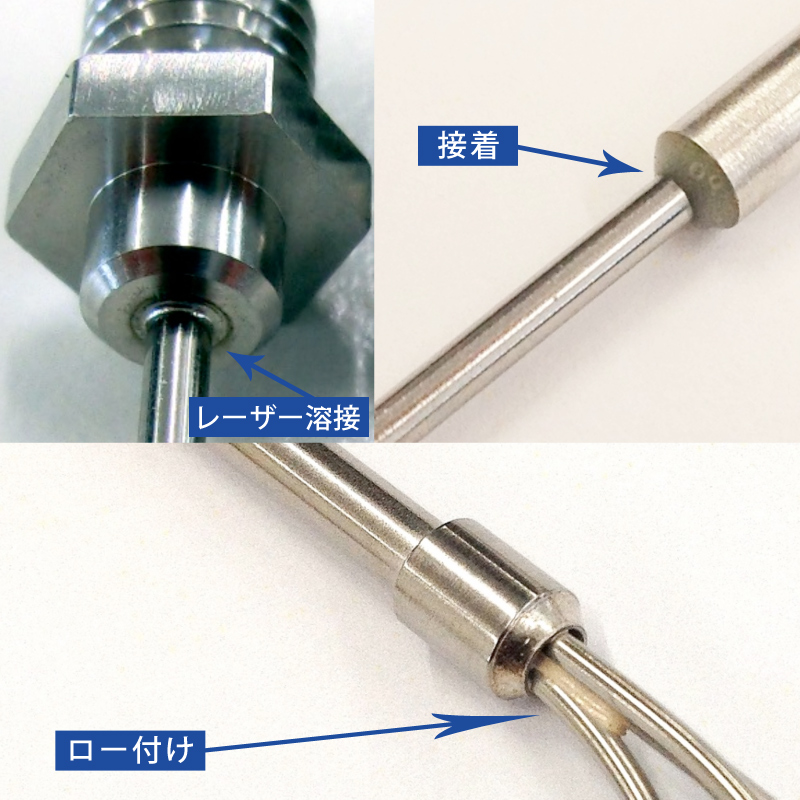

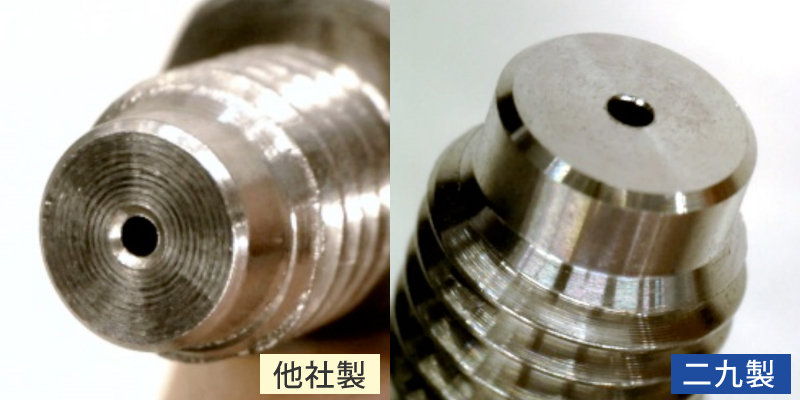

This section introduces the process through to the completion of the nozzle.

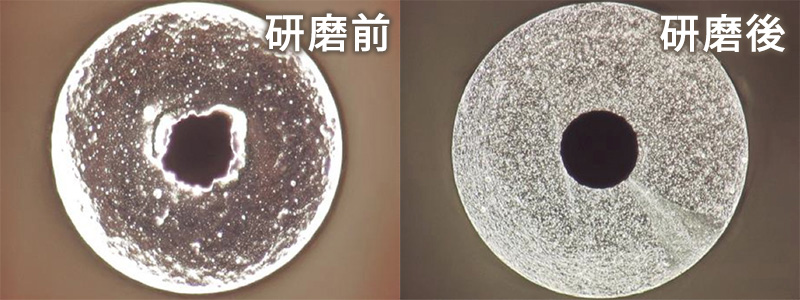

Among our nozzle assembly equipment, processing equipment such as pipe bore grinders,Designed and produced by the Kyoto Plant Development Section.

↓You can scroll horizontally.