HOME » INDEX for Quality

INDEX for Quality

INDEX for Quality

FUTA-Q Technologies for Quality

Testing Facilities

- Measuring Tools

- Leak Detection Testing Devices

- Strength Tester

- Online Factory Tour (Quality Management Div.)

- Clean Room

- Welding Environment and Inspection

Quality Assurance

In-house Developed Equipment

- Precision Inspector, the micro component discriminator

- PipeEndoscope, the non-destructive inner surface inspector

Inspection & Reliability

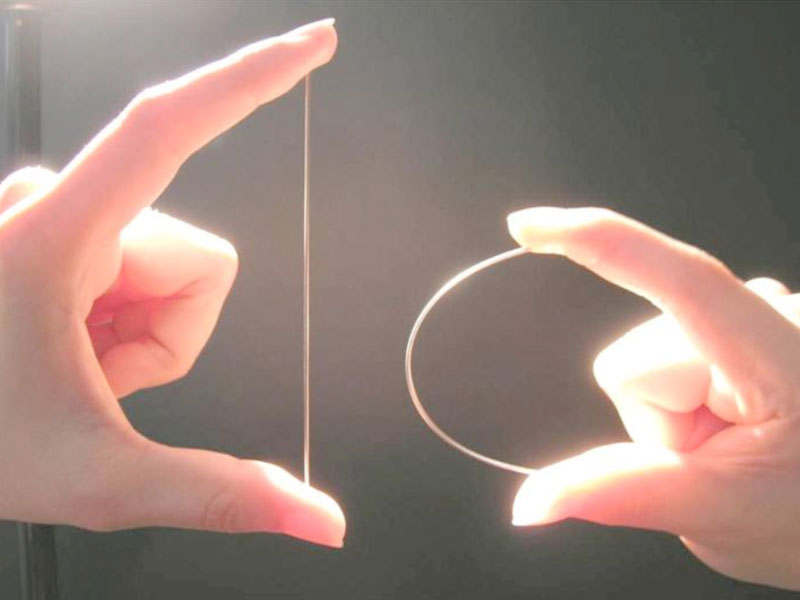

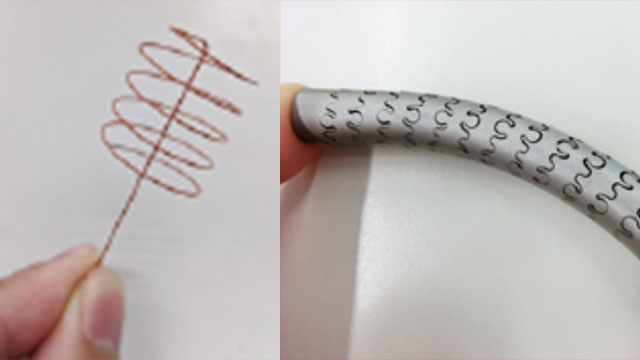

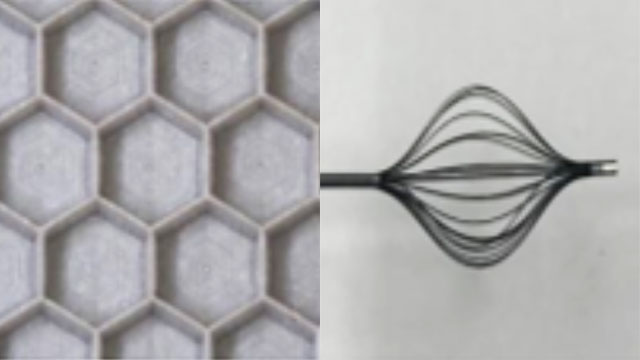

FUTA-Q’s pipes feature two

characteristics; super-elasticity and

shape-memory function. Nickel-titanium alloys are available in various shapes of

wire, small-diameter pipe, or sheet, with advanced processing such as laser cutting.

FUTA-Q’s pipes feature two

characteristics; super-elasticity and

shape-memory function. Nickel-titanium alloys are available in various shapes of

wire, small-diameter pipe, or sheet, with advanced processing such as laser cutting.

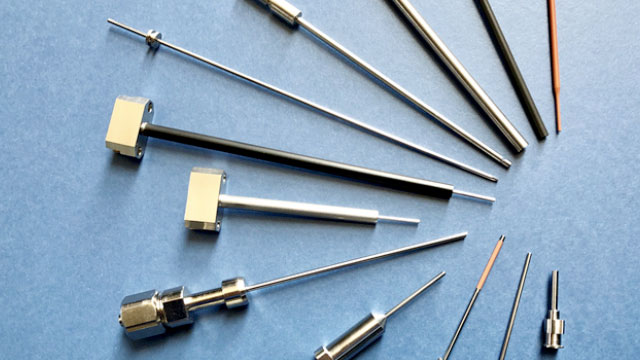

Our production system for pipes & wires covers

the all processes from machining to assembly, including inner surface polishing,

laser welding, and bending.

Our production system for pipes & wires covers

the all processes from machining to assembly, including inner surface polishing,

laser welding, and bending.

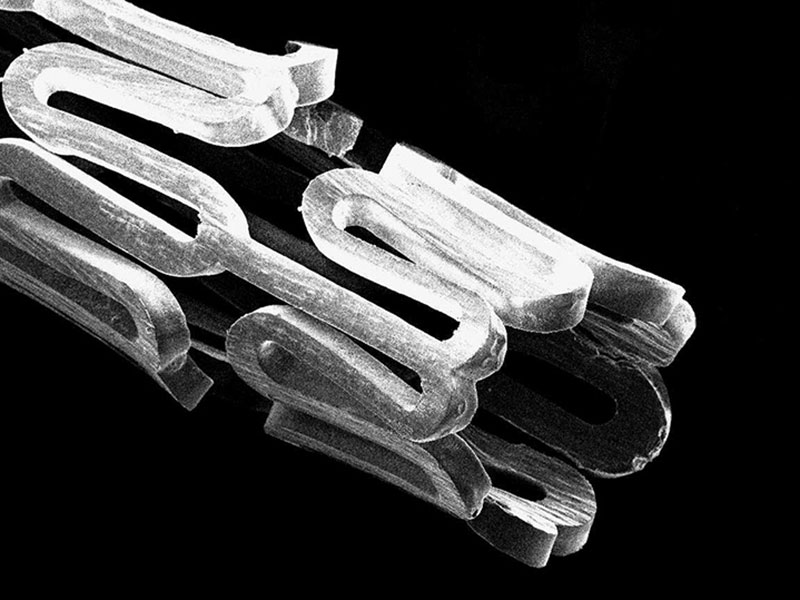

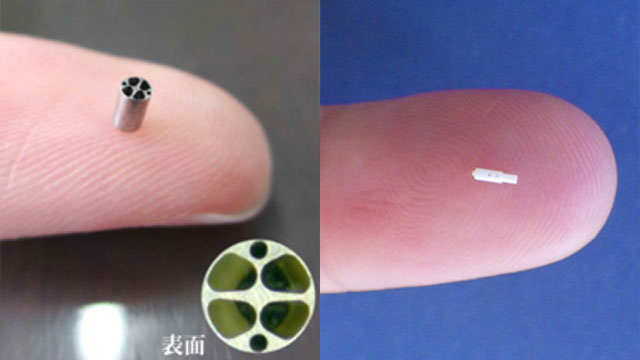

Medical parts require to be a smaller

size and to use a tougher material. Some clients request us to make microminiature

parts using titanium as well as ceramics.

Medical parts require to be a smaller

size and to use a tougher material. Some clients request us to make microminiature

parts using titanium as well as ceramics.

FUTA-Q

has newly developed FC-180 fluorine

thin-film coating having water/oil repellency and coating thickness of less than one

micrometer, which can withstand repeated washing with a sterilizing solution of

sodium hypochlorite.

FUTA-Q

has newly developed FC-180 fluorine

thin-film coating having water/oil repellency and coating thickness of less than one

micrometer, which can withstand repeated washing with a sterilizing solution of

sodium hypochlorite.

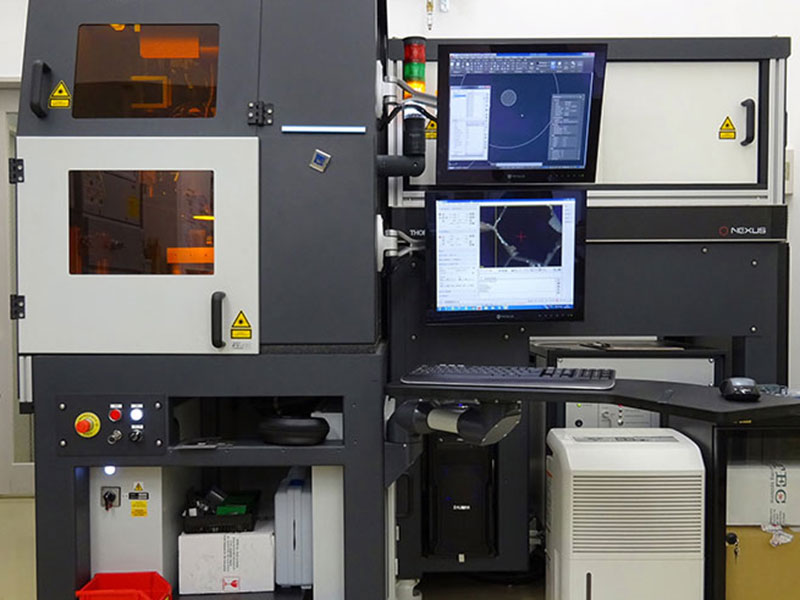

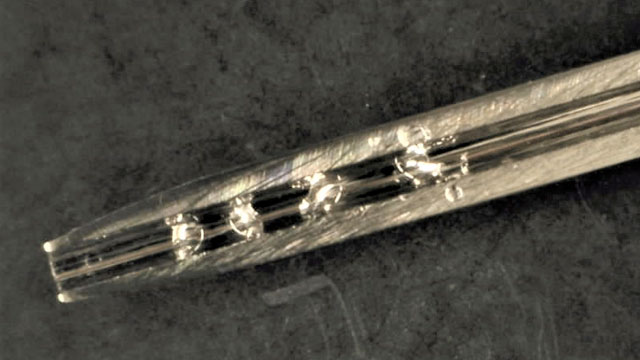

Femtosecond laser can process a work with

minimal thermal

effects using the ultra-short pulse laser. The inside of a transparent material can

be processed to form miniature shapes.

Femtosecond laser can process a work with

minimal thermal

effects using the ultra-short pulse laser. The inside of a transparent material can

be processed to form miniature shapes.

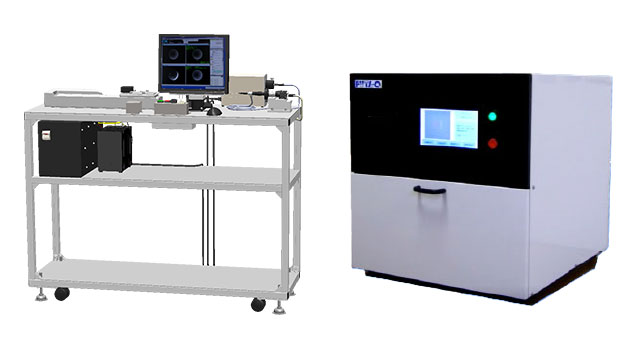

FUTA-Q has newly developed the

Precision Inspector, the non-destructive inner surface inspector, which can be used

for total number inspection of small diameter pipes. This is a non-destructive type,

and can automatically measure inner surface roughness and also detect scratches and

residues on the inner surface like endoscopes can.

FUTA-Q has newly developed the

Precision Inspector, the non-destructive inner surface inspector, which can be used

for total number inspection of small diameter pipes. This is a non-destructive type,

and can automatically measure inner surface roughness and also detect scratches and

residues on the inner surface like endoscopes can.